Ship toilet negative-pressure screw pushing gas-liquid conveying device

A conveying device and gas-liquid technology, which is applied in the field of gas-liquid conveying devices and conveying devices, can solve the problems of strong odor and unclean cleaning, and achieve the effect of simple structure, good deodorizing effect and clean cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

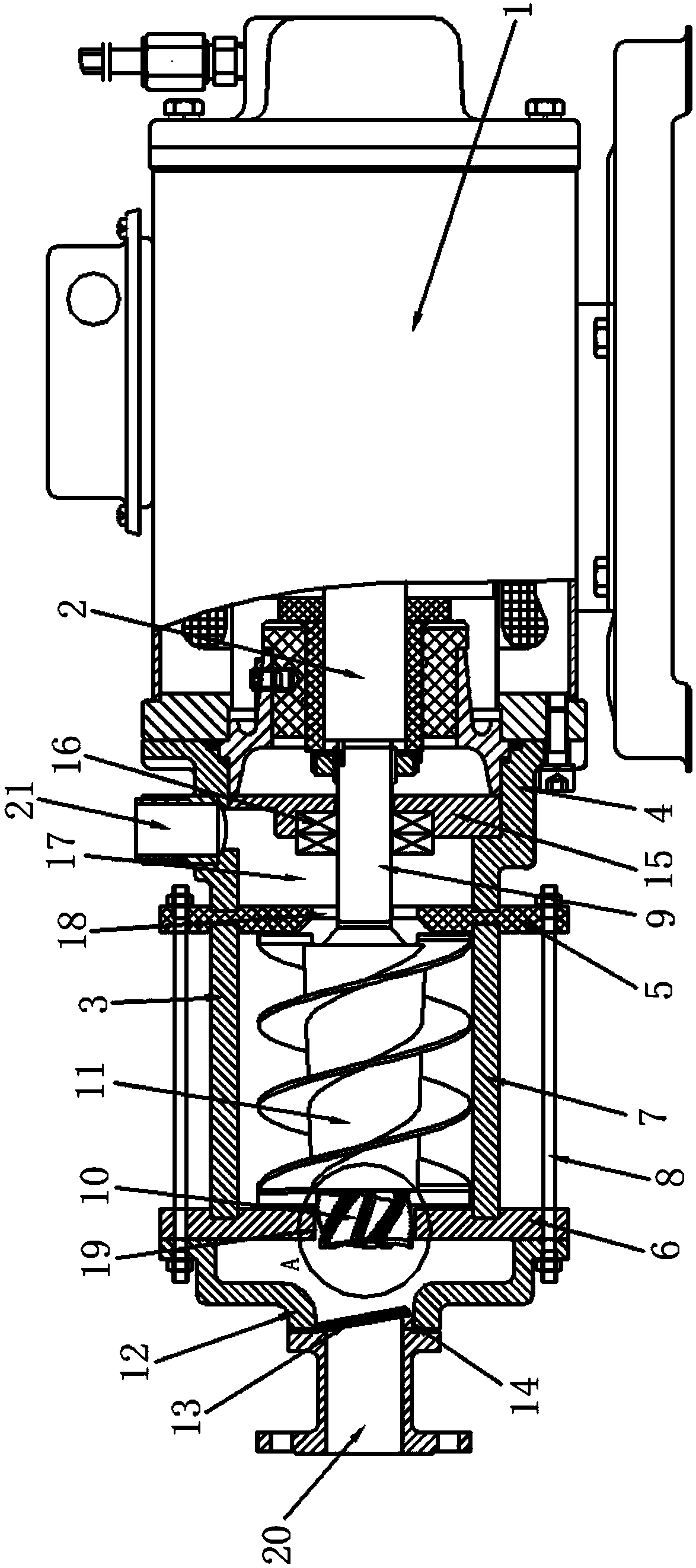

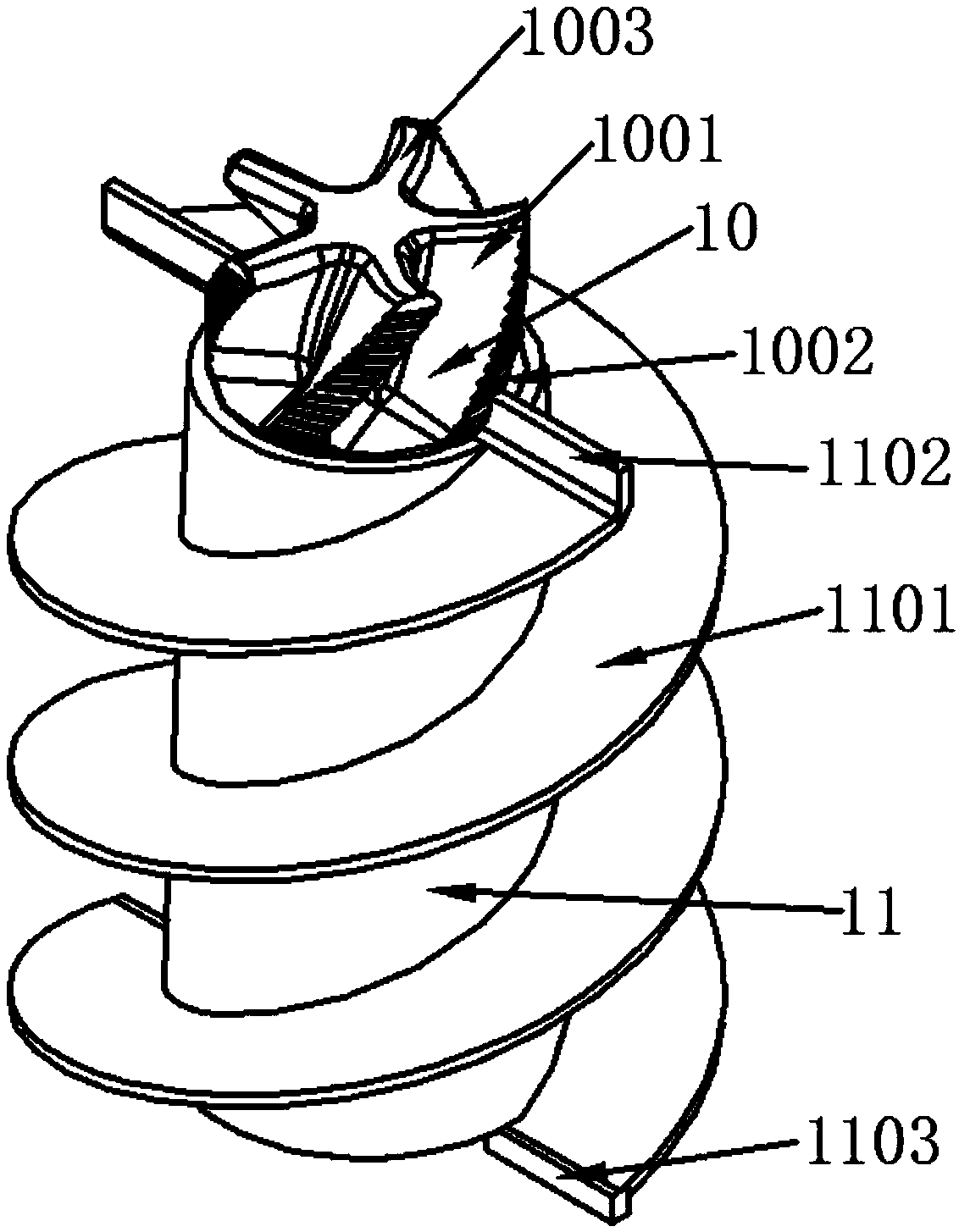

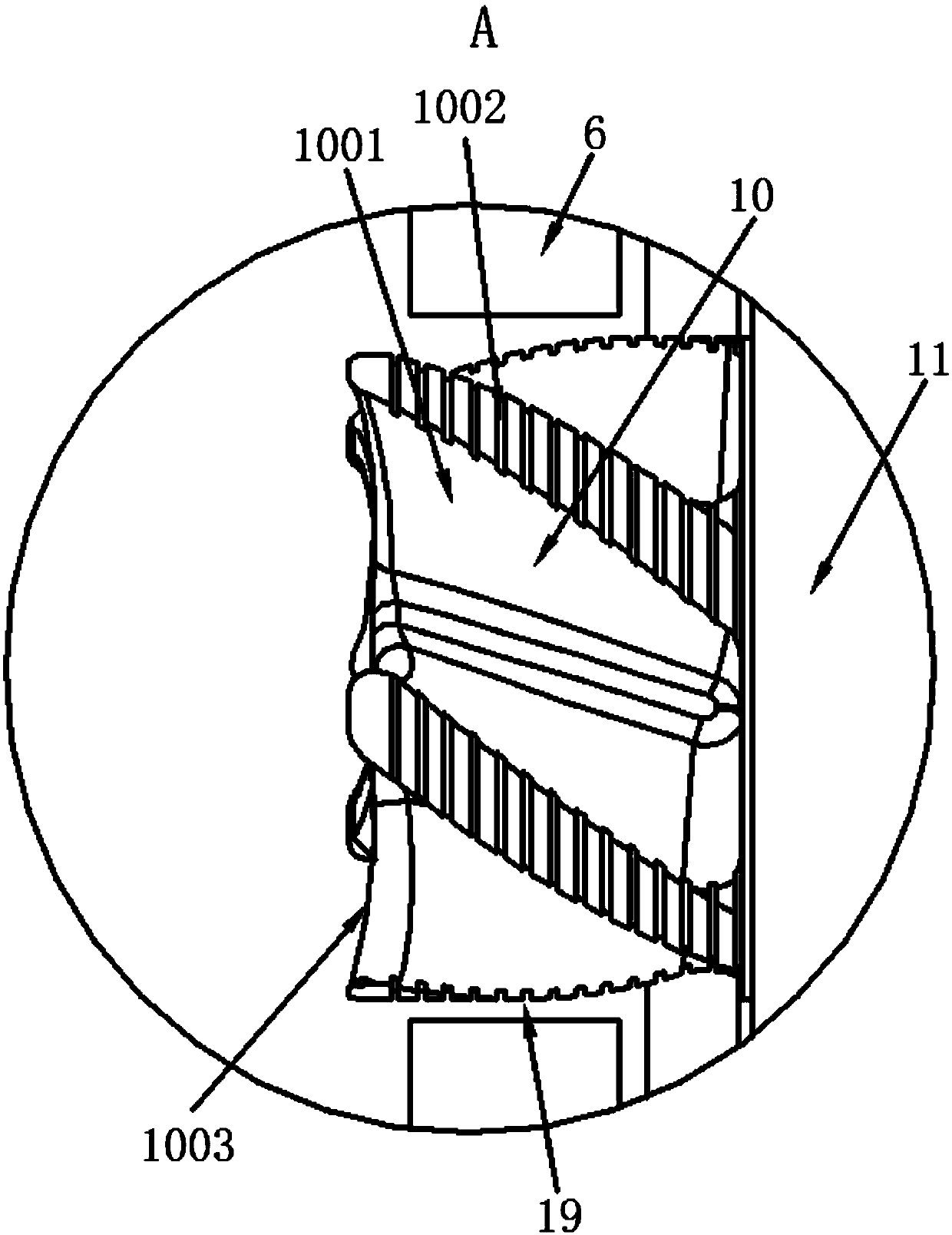

[0017] refer to Figure 1-Figure 3 , a negative pressure rotary gas-liquid conveying device for marine toilets of the present invention, comprising a motor 1, a gas-liquid conveying device 3, a conveying shaft 9, a non-return baffle 13, a sewage inlet 20 and a sewage discharge port 21, one end of the motor 1 A motor connector 4 is connected, and an air-liquid delivery device 3 is connected to one end of the motor connector 4. The gas-liquid delivery device 3 includes a first connecting plate 5, a second connecting plate 6, a ring column 7, and a delivery terminal 10 , screw sleeve 11 and inlet end cover 12, one end of the output shaft of the motor 1 is connected with a conveying shaft 9, and the conveying shaft 9 passes through the round hole and the sealing sleeve 16 on the partition plate 15 inside the motor connector 4, and the sealing sleeve 16 Set in the round hole; one end of the motor connector 4 is connected to the side of the first connecting plate 5, a ring column 7 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Helix angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com