Vacuum preloading device with sandbag cushion layer, and construction method thereof

A sandbag and preloading technology, which is applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of vacuum tube failure, increased reinforcement area, and increased sand consumption, so as to avoid damage, reduce fluidity, and improve The effect of overall structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

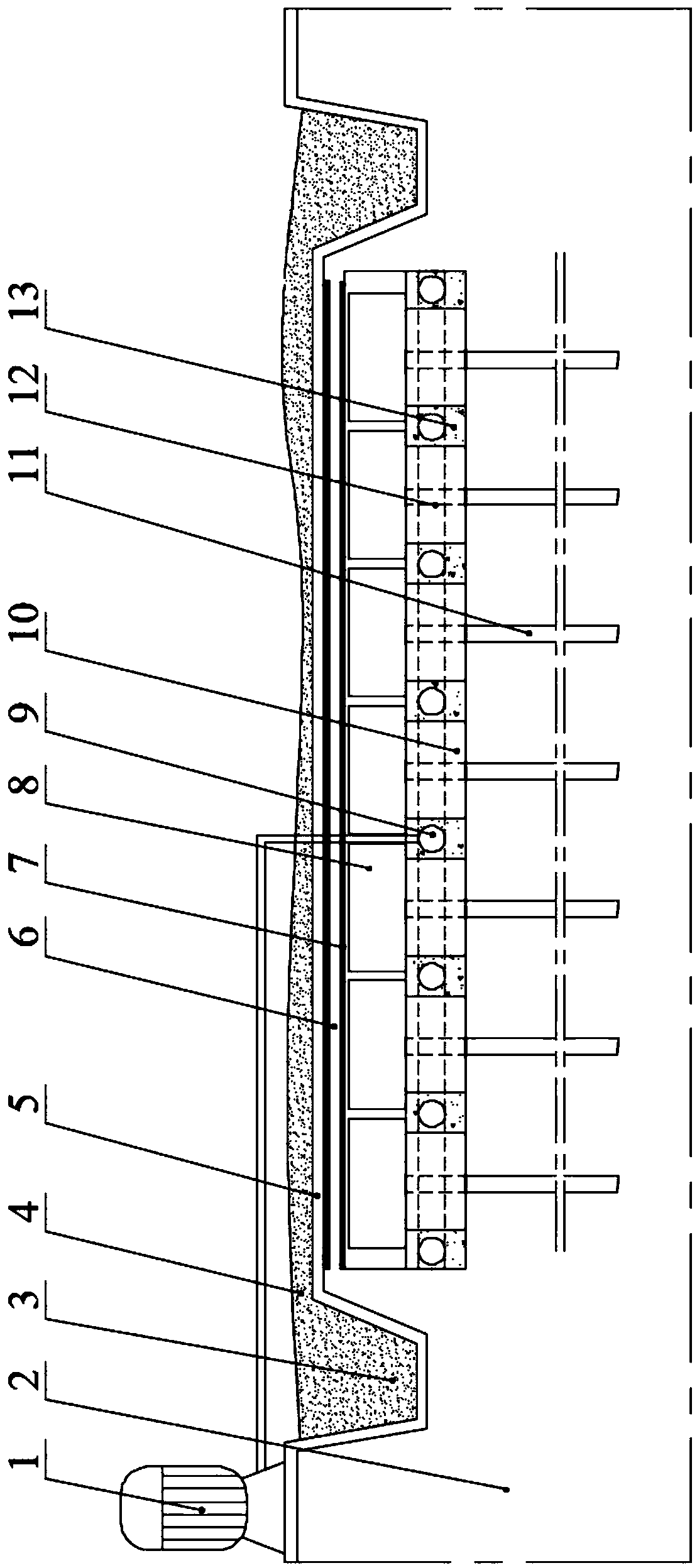

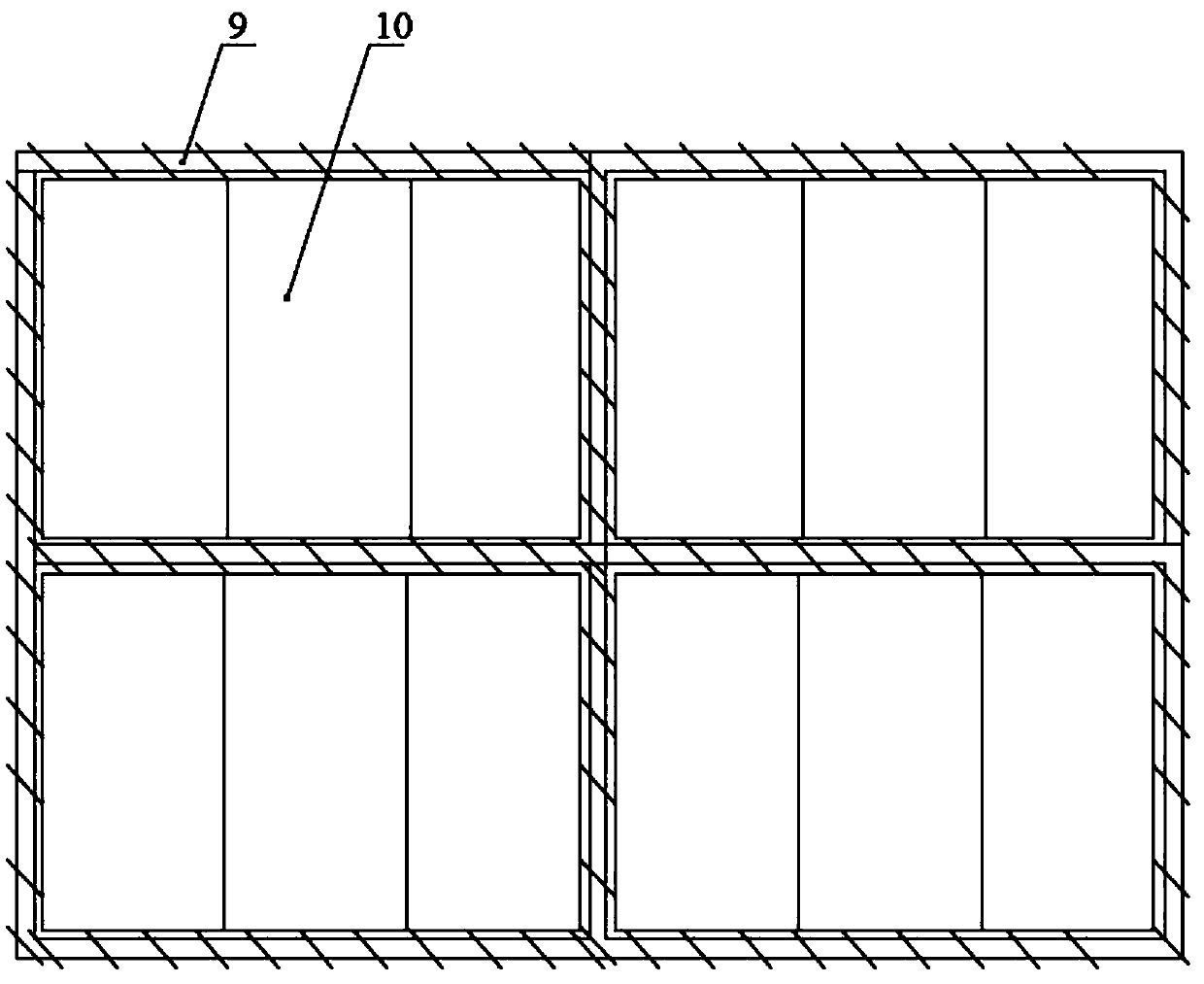

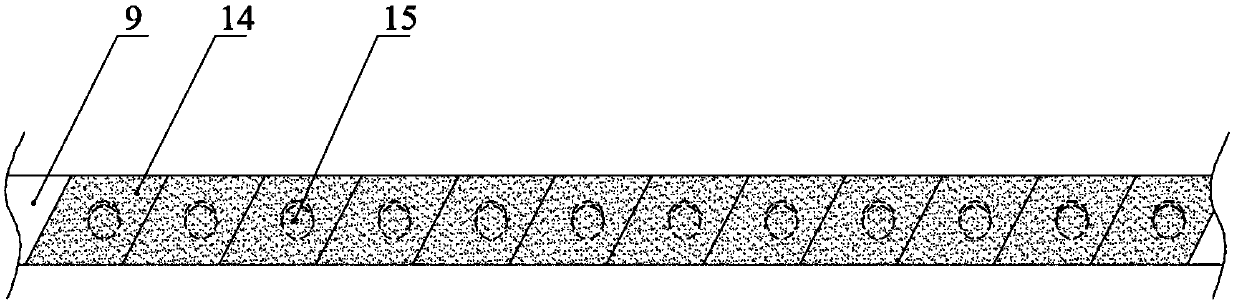

[0044] A vacuum preloading device with a sandbag cushion and a construction method thereof of the present invention are especially suitable for reinforcement of muddy soil, miscellaneous filling soil and intertidal zone soft soil. Among them, the horizontal sandbag layer and the vertical sandbag layer made of splicing sandbags form a multi-layer "sand blanket" arranged vertically and horizontally, which can improve the overall stability of the horizontal drainage system in the prior art and avoid direct contact between sand and soil. A series of problems such as failure of sand fractures and damage to vacuum tubes have indirectly increased the rate of vacuum diffusion and drainage efficiency. The connection between sandbags, vacuum pipes and plastic drainage boards is simple, easy to arrange and construct on site. Compared with traditional paving methods, sand resources can be recycled and reused. On the whole, the method is more simple and green.

[0045] The specific imple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com