Cloth polar fleece forming device and forming process

A technology of forming equipment and cloth, applied in heating/cooling fabrics, textiles and papermaking, roughening and other directions, can solve the problems of low work efficiency, low forming quality, high energy consumption for setting, etc., and achieve the effect of high forming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

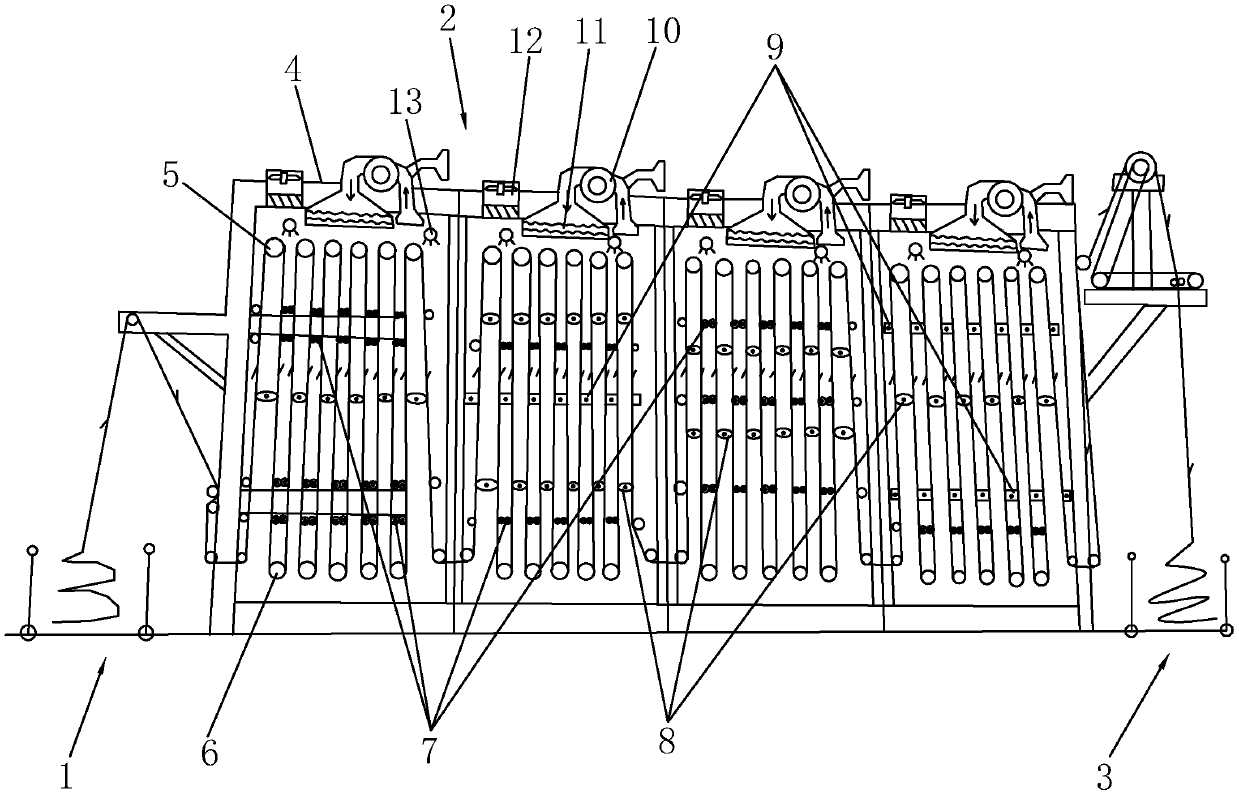

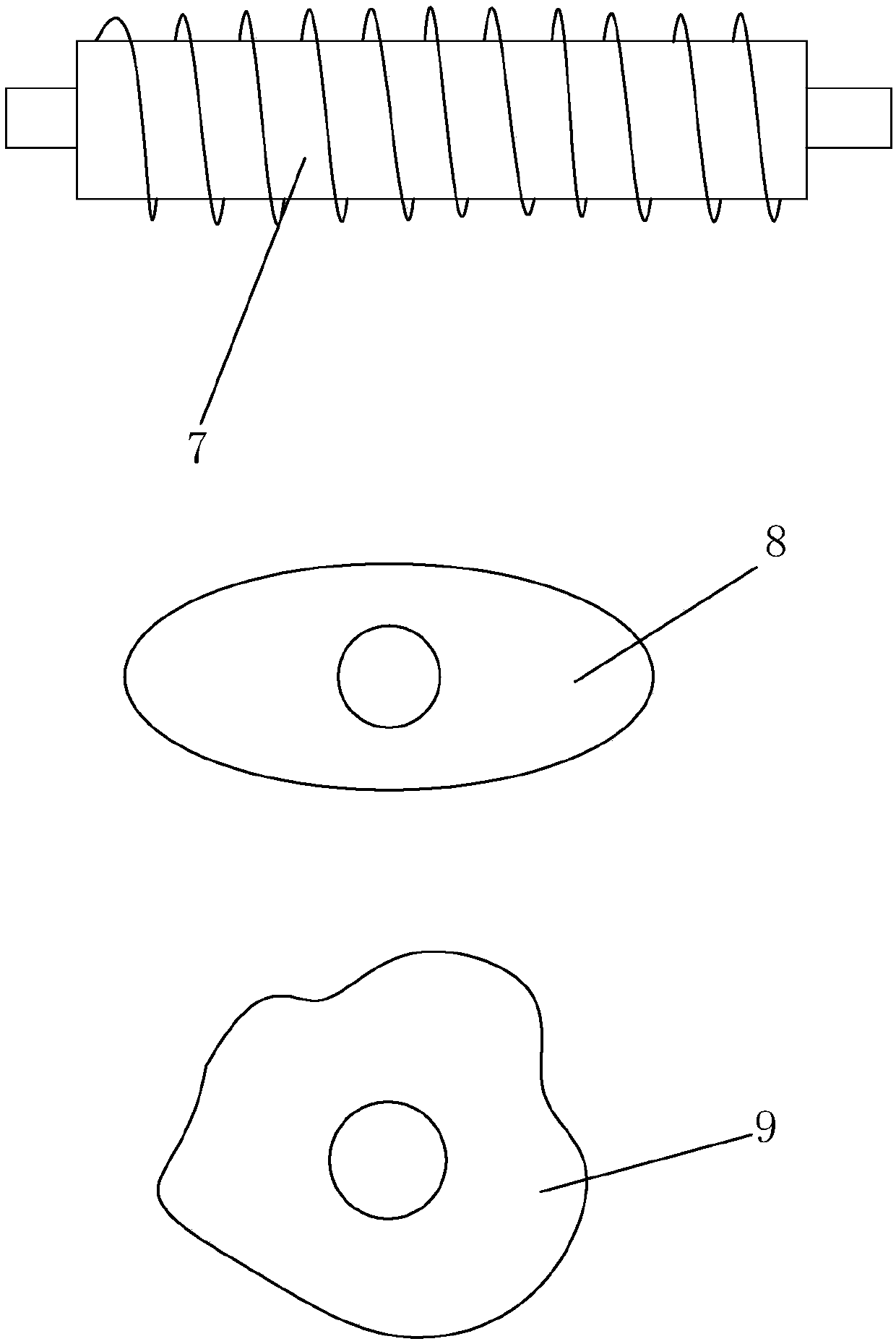

[0023] Embodiment 1: a kind of cloth shake grain forming equipment, such as figure 1 As shown, it includes a cloth feeding device 1, a shaker molding device 2, and a cloth outlet device 3. The cloth feeder 1 is mainly composed of several cloth guide rollers driven by a motor to transfer the cloth to the shaker forming device 2, and the shaker The molding device 2 can be provided with a plurality of boxes 4, each box 4 is used as an independent unit, and an upper cloth guide roller 5 and a lower cloth guide roller 6 are arranged in the box body 4, both of which are driven by a motor to rotate. Between the upper cloth guide roller 5 and the lower cloth guide roller 6, there are several left and right forming rollers 7, beating forming roller one 8, and beating forming roller two 9; observation windows are provided on the box body 4 for convenient observation of the box body 4 internal conditions, so as to achieve the function of being able to stop and adjust at any time.

[002...

Embodiment 2

[0027] Embodiment 2: A process for forming cloth eccentric particles, including producing by the cloth eccentric granule forming machine of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com