A device for lifting the mass of the tooth-by-tooth heating end with a guide block

A guide block and heating end technology, applied in the field of heat treatment, can solve the problems of poor end quality, difficult control and adjustment, etc., and achieve the effects of reducing processing costs, reducing accumulated processing errors, and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

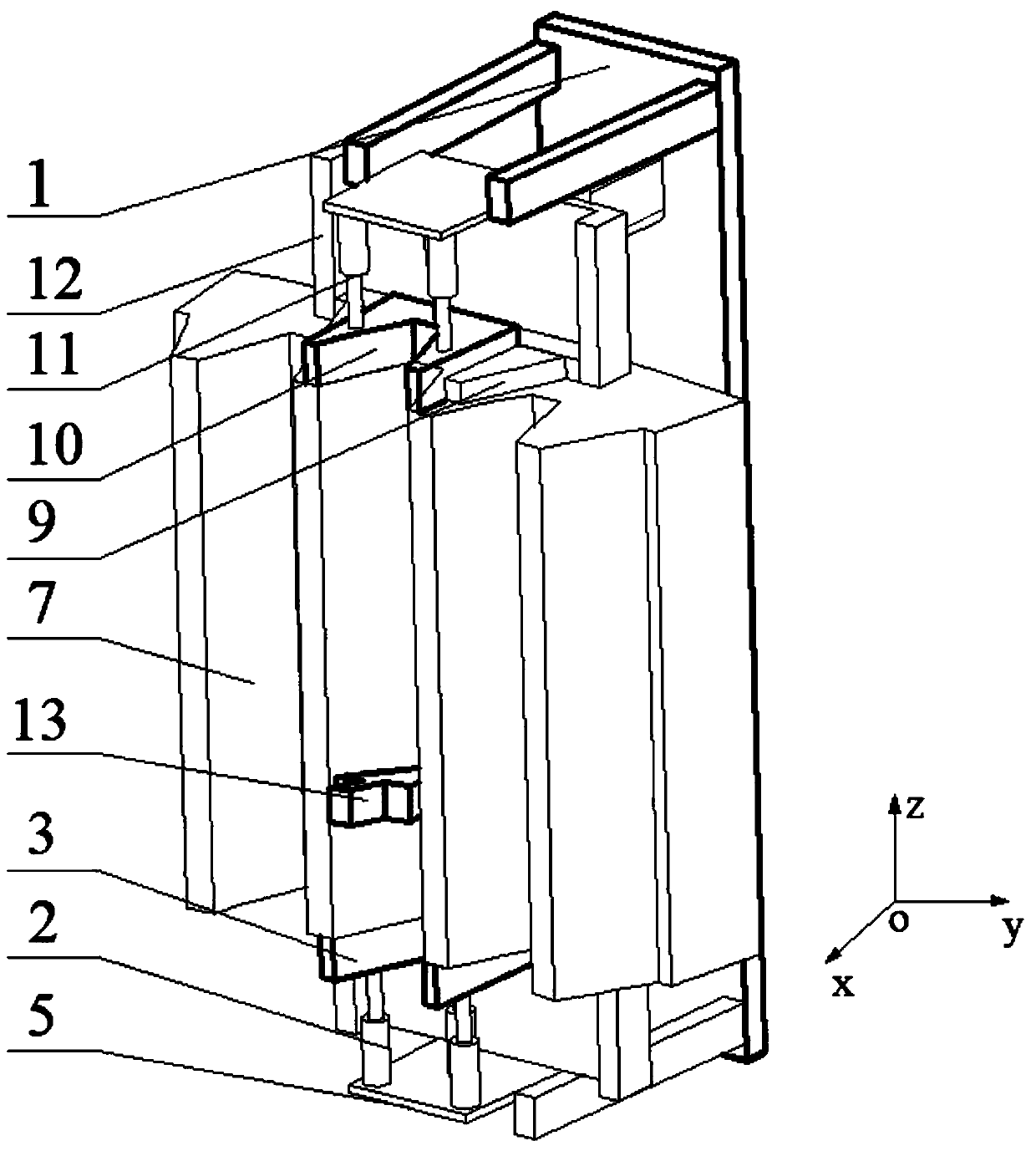

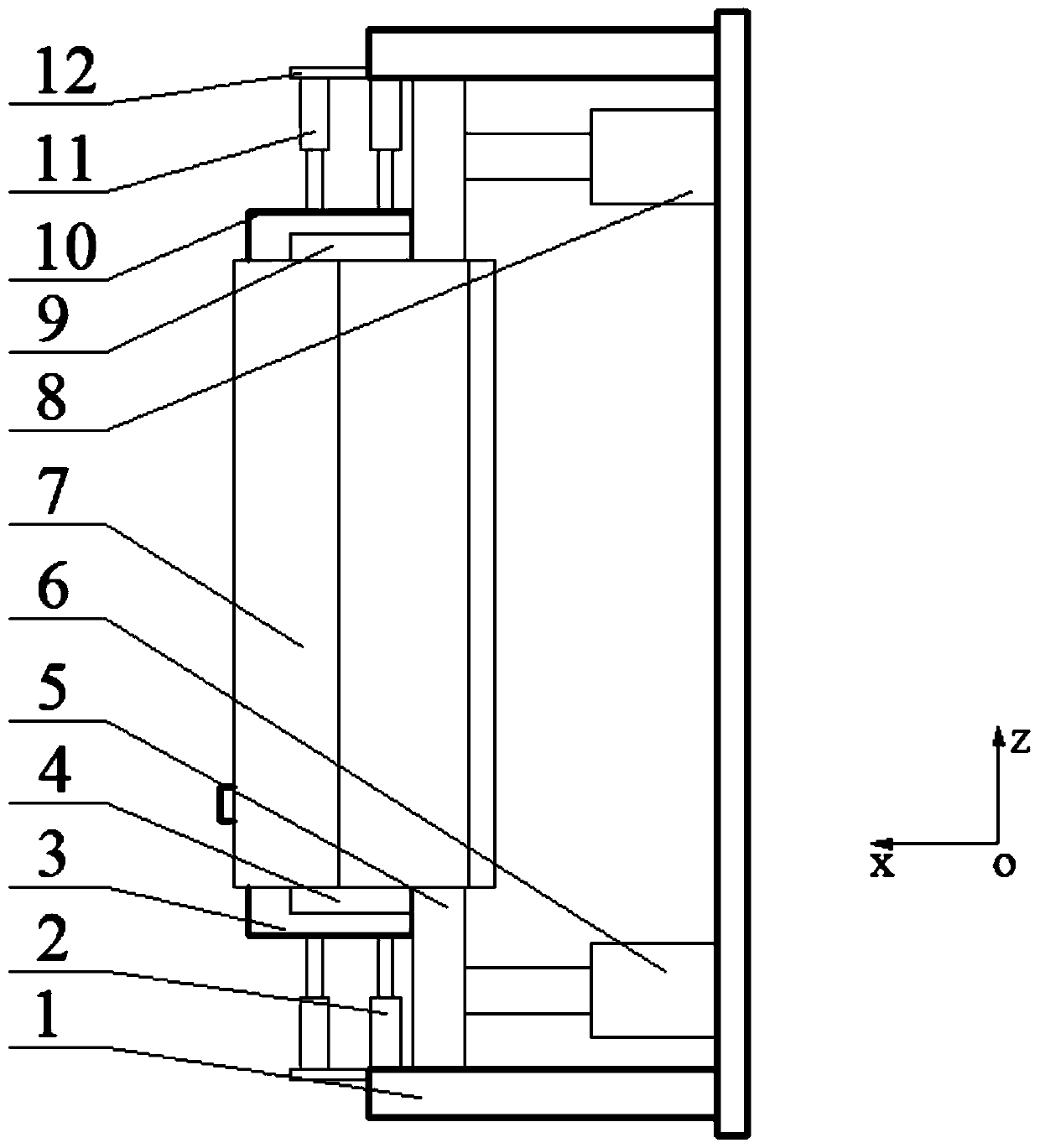

[0022] In order to detail the technical content, structural features, achieved goals and effects of the present invention, the following will be described in detail in conjunction with the accompanying drawings.

[0023] The present invention is a device for lifting the quality of the end part of the heating by the guide block, and the specific structure is as follows: figure 1 and figure 2 shown. The device of the present invention for improving the quality of the end of the guide block heating tooth by tooth includes a cage 1, an upper pressing mechanism 11, an upper guiding block 10, an upper clamping mechanism 9, an upper fixing frame 12, an upper adjustment mechanism 8, and a lower pressing mechanism 2. The lower guide block 3, the lower clamping mechanism 4, the lower fixing frame 5 and the lower adjusting mechanism 6. The shape of the cage 1 is rectangular, and it is used to fix and place the overall structure. Two rectangular columns protrude from the upper and lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com