Sludge carbonizing method

A technology of sludge and carbonization system, which is applied in biological sludge treatment, pyrolysis sludge treatment, dehydration/drying/concentrated sludge treatment, etc. It can solve the problems of laborious cutting into small pieces, low drying efficiency and easy generation of sludge Odor and other problems, to achieve the effect of increasing the specific surface area, conducive to drying, and avoiding health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

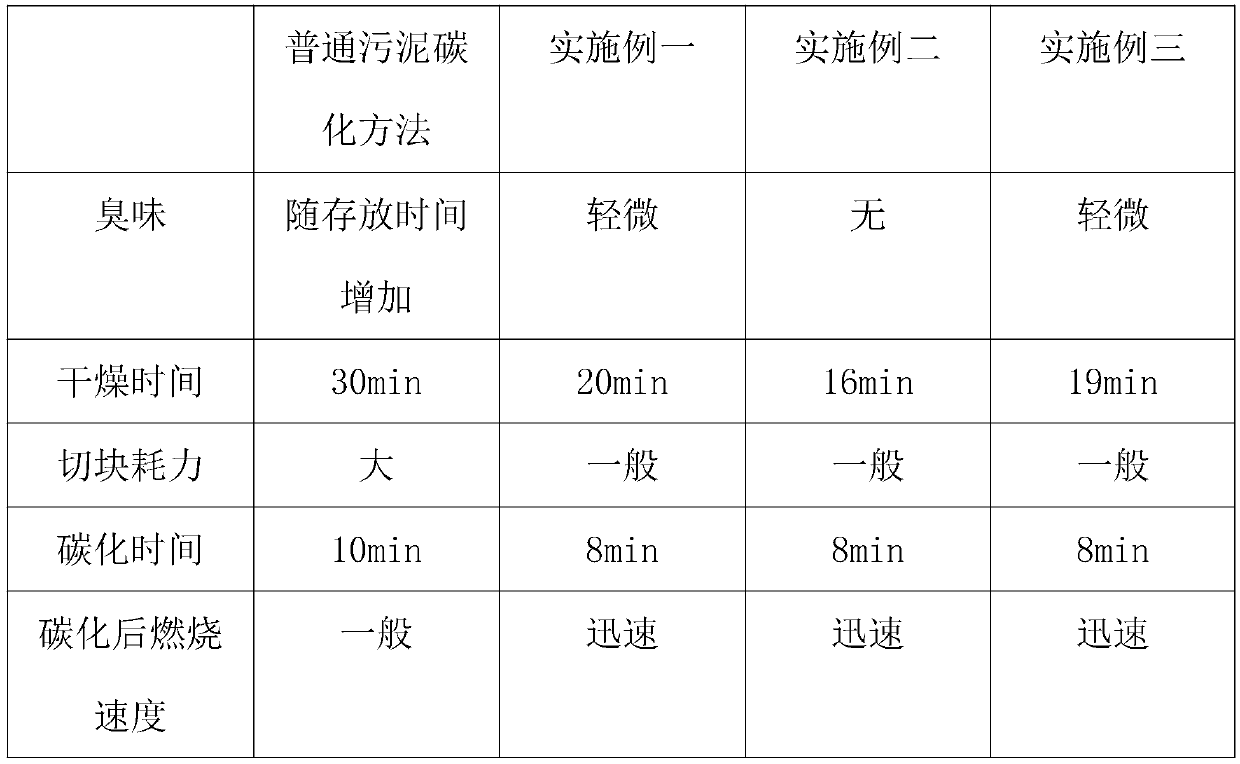

Examples

Embodiment 1

[0027] A sludge carbonization method, comprising the following steps,

[0028] (1) Sludge deodorization, configure deodorizing bacteria according to the formula, add deodorizing bacteria after the sludge is heated up, stir and let it stand for 2 hours;

[0029] (2) Drying, sending the sludge into the drier to dry to a water content of 85%, then use a press to press into a honeycomb shape, put it into the drier and continue drying until the water content is 70%;

[0030] (3) carbonization, chop the dried sludge into small pieces, pressurize it and send it into the carbonization system, and cool to room temperature after carbonization;

[0031] (4) Recycling, the carbonized sludge is pressed into a net shape, and three pieces of carbonized sludge nets are used to overlap to form a simple filter device, and the sludge in step (1) is passed through the filter device for deodorization. ;

[0032] (5) Carbonized sludge treatment, the filtered carbonized sludge net is dried and use...

Embodiment 2

[0042] A sludge carbonization method, comprising the following steps,

[0043] (1) Sludge deodorization, configure deodorizing bacteria according to the formula, add deodorizing bacteria after the sludge is heated up, stir and let it stand for 2-10 hours;

[0044] (2) Drying, sending the sludge into the drier to dry to a water content of 88%, then use a press to press into a honeycomb shape, put it into the drier and continue drying until the water content is 75%;

[0045] (3) carbonization, chop the dried sludge into small pieces, pressurize it and send it into the carbonization system, and cool to room temperature after carbonization;

[0046] (4) Recycling, pressing the carbonized sludge into a net shape, using 4 carbonized sludge nets to overlap to make a simple filter device, passing the sludge in step (1) through the filter device and then performing deodorization ;

[0047] (5) Carbonized sludge treatment, the filtered carbonized sludge net is dried and used for burni...

Embodiment 3

[0057] A sludge carbonization method, comprising the following steps,

[0058] (1) Sludge deodorization, configure deodorizing bacteria according to the formula, add deodorizing bacteria after the sludge is heated up, stir and let it stand for 10 hours;

[0059] (2) Drying, sending the sludge into the drier to dry to a water content of 90%, then use a press to press into a honeycomb shape, put it into the drier and continue drying until the water content is 80%;

[0060] (3) carbonization, chop the dried sludge into small pieces, pressurize it and send it into the carbonization system, and cool to room temperature after carbonization;

[0061] (4) Recycling, the carbonized sludge is pressed into a net shape, and 5 carbonized sludge nets are overlapped to make a simple filter device, and the sludge in step (1) is passed through the filter device for deodorization ;

[0062] (5) Carbonized sludge treatment, the filtered carbonized sludge net is dried and used for burning.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com