Anti-clogging device and garbage compression station with the same

A garbage compression station and plugging technology, which is applied in the direction of garbage transmission, garbage collection, storage devices, etc., can solve the problems of garbage plugging on the compression chamber, increasing the labor intensity of operators, and ineffective emptying of the compression pusher. It achieves the effect of low labor intensity, good effect of breaking the canopy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

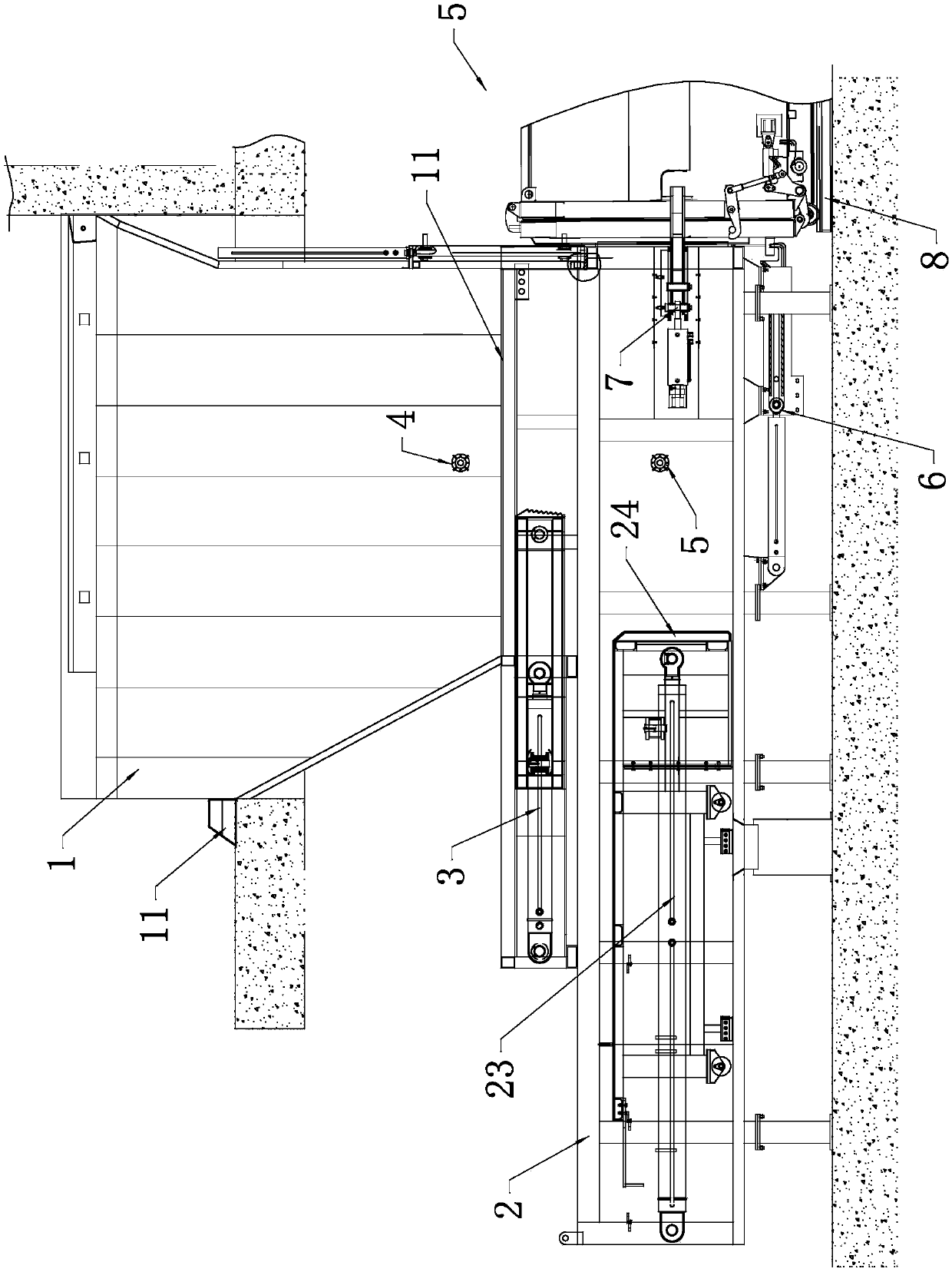

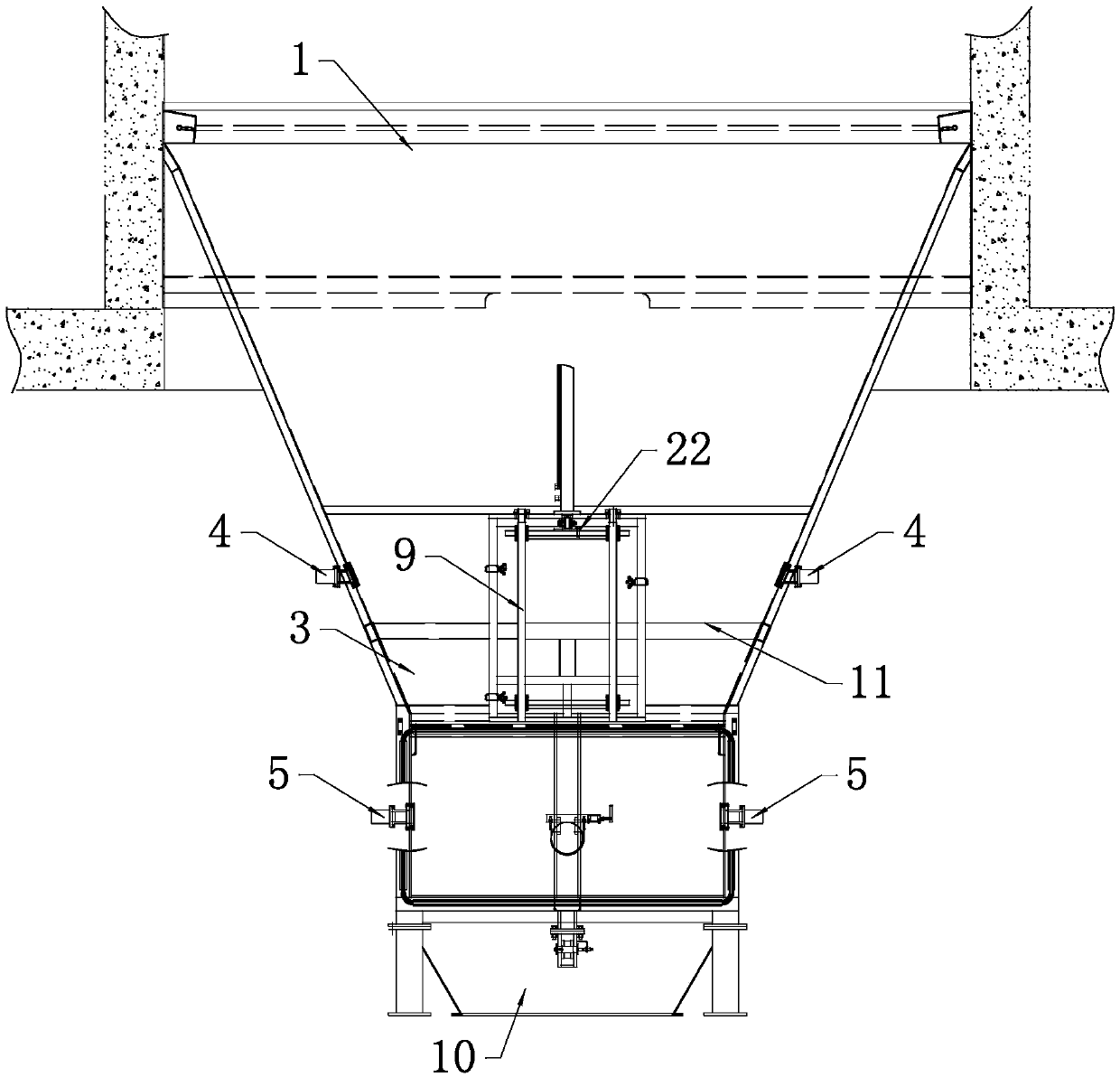

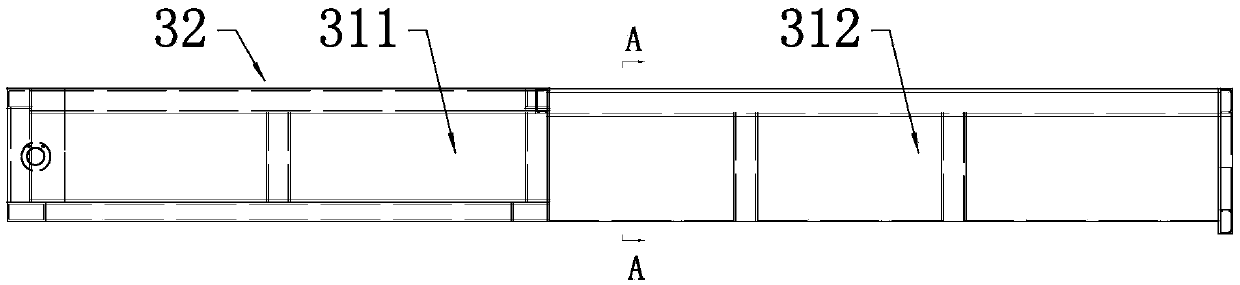

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 As shown together, a garbage compression station equipped with an anti-clogging device includes a discharge bin 1 and a compression chamber 2 arranged up and down, and also includes an anti-clogging device 3 . Anti-canopy blocking device comprises breaking canopy blocking work room 31 and the breaking canopy blocking pushing head 32 that is arranged on the inside of breaking canopy blocking work room 31. The canopy-breaking push head 32 moves horizontally in the canopy-breaking workroom 31, and the canopy-clogging garbage is forcibly crushed to realize the canopy-clogging of the clogged garbage. The tent breaking workshop 31 includes a first chamber 311 and a second chamber 312 which are communicated with each other. The first chamber 311 is equipped with a tent breaking push head 32 . The cavity side of the second cavity 312 is a smooth inner wall. The inner side wall is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com