Energy-saving and environment-friendly 3D printing powder conveying device

A powder conveying device and 3D printing technology, applied in the field of 3D printing, can solve problems such as environmental pollution, and achieve the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

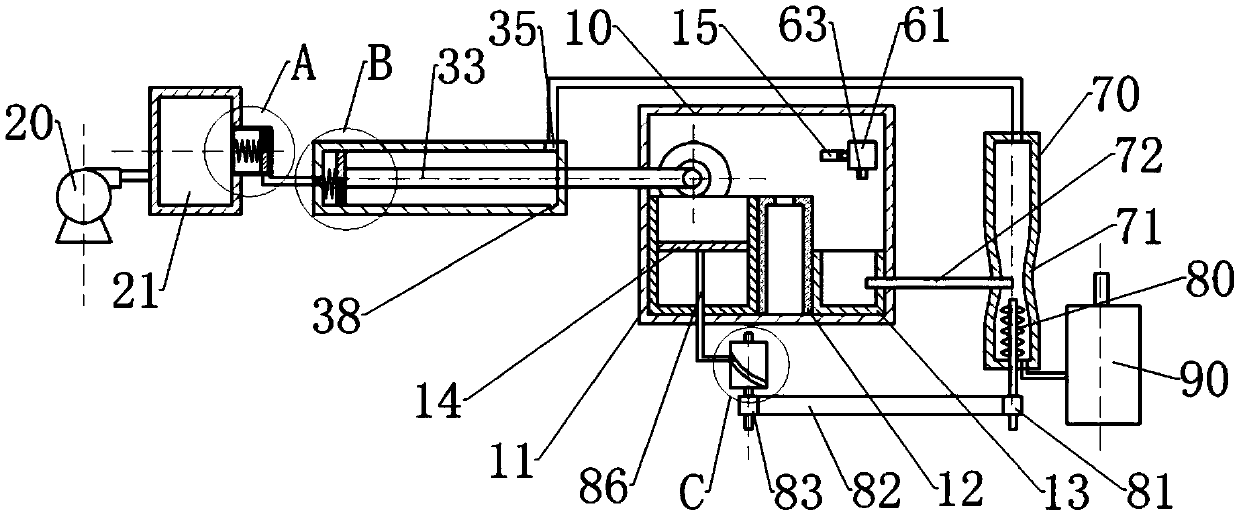

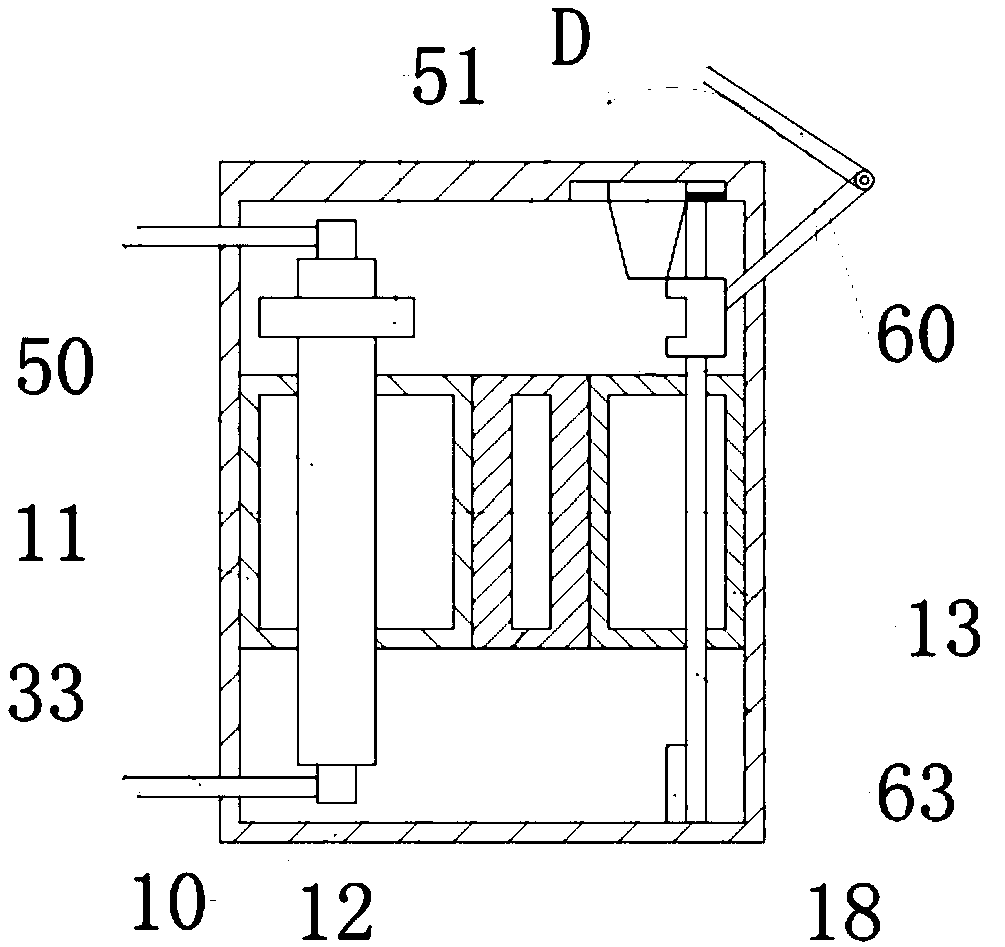

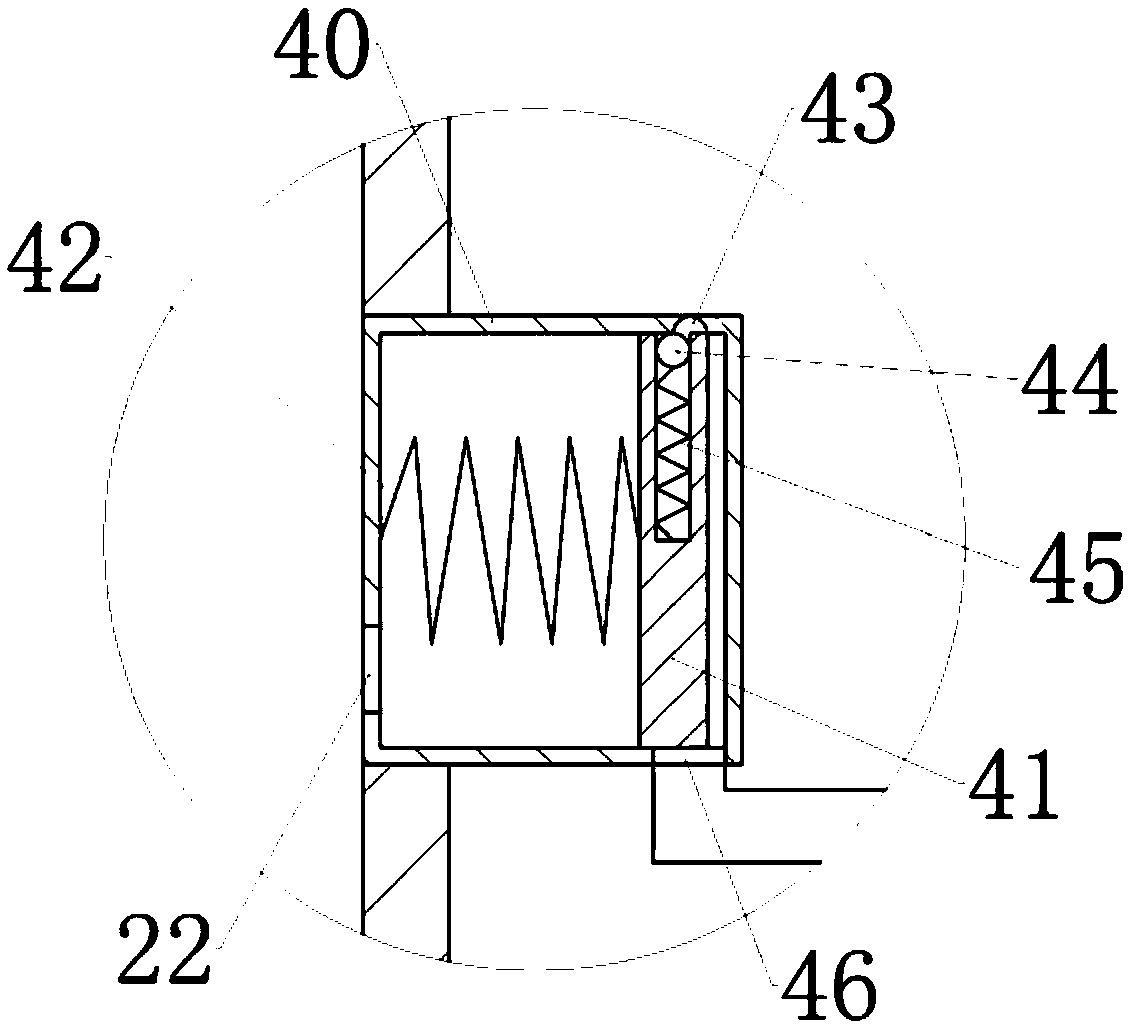

[0034] The following is further described in detail through specific implementation methods:

[0035] The reference signs in the drawings of the description include: box body 10, discharge box 11, workbench 12, material receiving box 13, electric heating plate 14, a slider 15, a chute 16, first spring 17, motor switch 18. Air pump 20, gas storage tank 21, gas storage tank outlet 22, first piston cylinder 30, first piston 31, second spring 32, first piston rod 33, one-way intake valve 34, first piston cylinder row Air port 35, third spring 36, first ball 37, first arc groove 38, second piston cylinder 40, second piston 41, fourth spring 42, second arc groove 43, second ball 44 , the fifth spring 45, the second piston cylinder exhaust port 46, the roller 50, the scraper 51, the crank 60, the b slider 61, the slider groove 62, the b chute 63, the Venturi tube 70, the throat 71, Suction pipe 72, turbine 80, first pulley 81, belt 82, second pulley 83, cylindrical cam 84, block 85, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com