An e-waste recycling device that prevents sucked-out solder from reflowing through the bracket limit

A technology of electronic waste and recovery device, which is applied in the direction of transportation and packaging, solid waste removal, chemical instruments and methods, etc. It can solve the problem that solder is easy to stick to the inner wall of the equipment, which affects the recovery work, and it is difficult to find electrical filaments. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

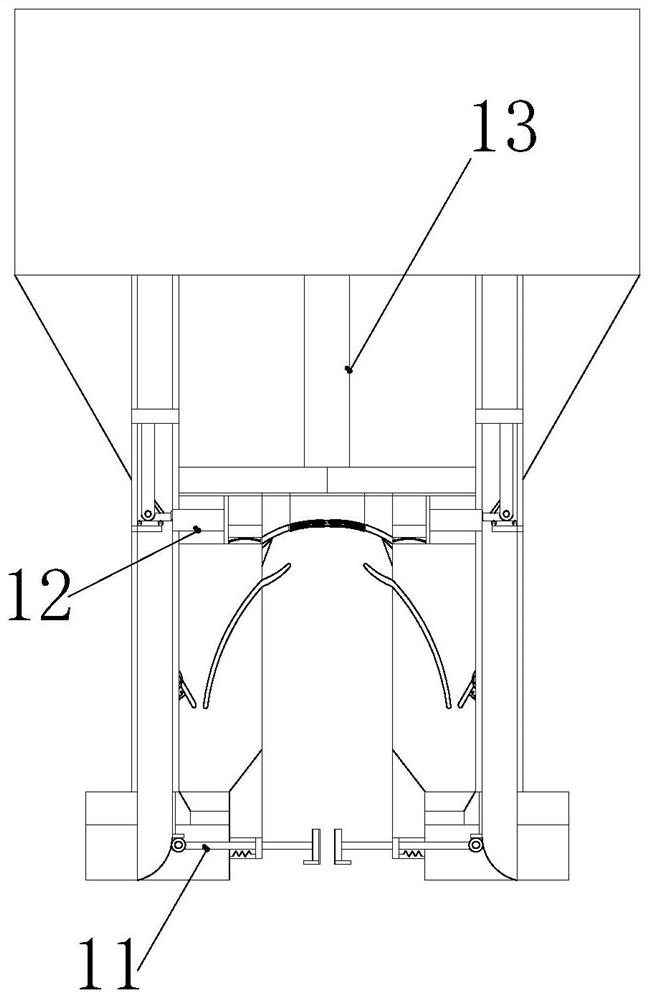

[0027] see figure 1, the present invention provides an electronic waste recovery device that prevents solder from being sucked out and reflowed through the limit of the bracket. The device 1 is located on the lower end surface of the device housing 4 and is movably connected with the device housing 4. The card slot 2 is located inside the device housing 4 and is movably connected with the device housing 4. The hose 5 is located in the device housing. The upper surface of the body 4 is connected to the device housing 4 at the same time, the adjustment block 3 is located on the outer surface of the card slot 2 and is in clearance fit with the card slot 2, and the hose 5 is connected to the external negative pressure fan through the Together, the direction can be adjusted conveniently through the hose 5 so as to be connected with the external negative pressure fan.

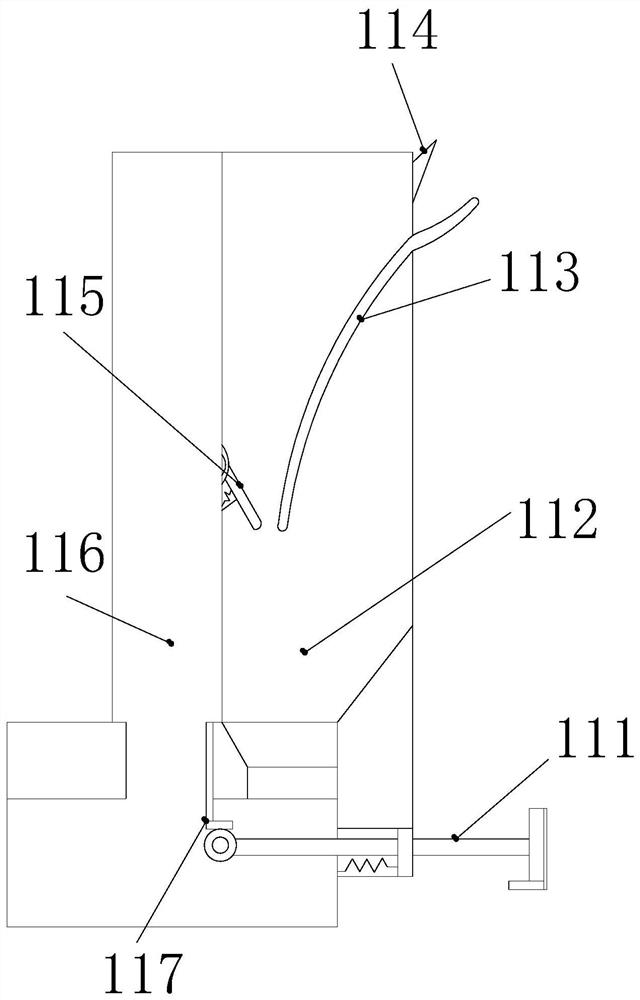

[0028] see figure 2 , the present invention provides an electronic waste recovery device that prevents sucked o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com