Processing mixer for lubricating grease blending

A technology for lubricating grease and mixers, which is applied in mixers, shaking/oscillating/vibrating mixers, mixers with rotating stirring devices, etc. It can solve the problems of small stirring force and amplitude of stirring rods, difficulty in mixing oils and fats, etc. , to achieve the effect of improving the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

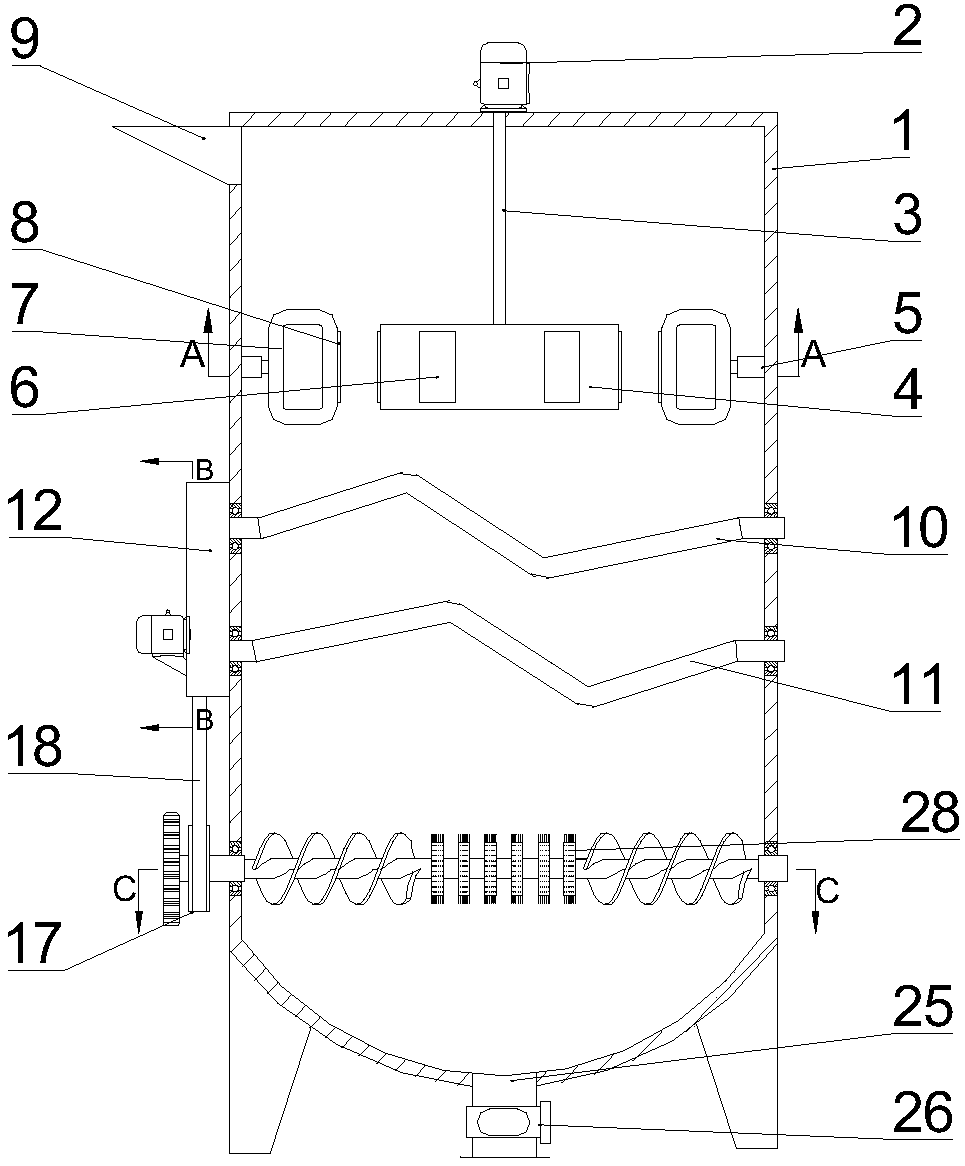

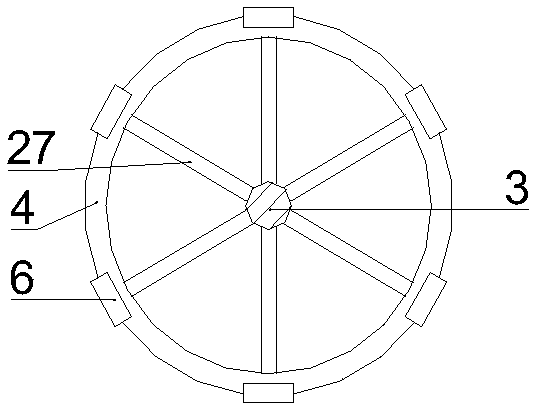

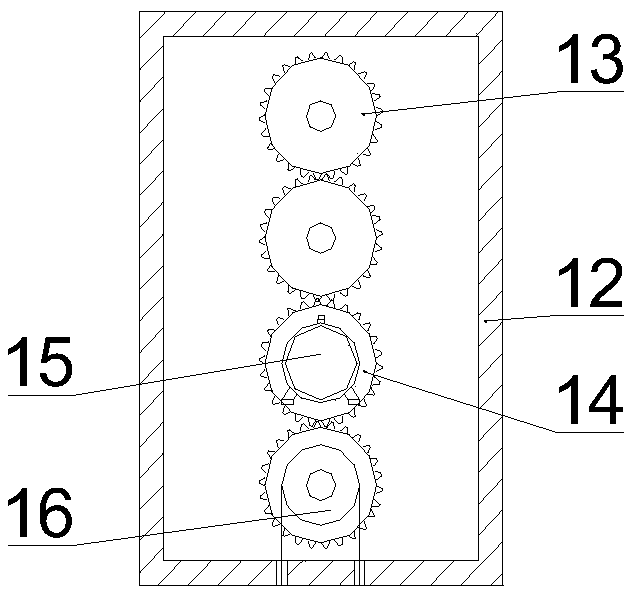

[0019] see Figure 1-4 , a processing mixer for lubricating grease blending, comprising a tank body 1, the inside of the tank body 1 is provided with a rotating ring 4, the surface of the rotating ring 4 is evenly and fixedly connected with a plurality of first magnets 6, and the adjacent first magnets The directions of the magnetic south pole and the magnetic north pole of 6 are opposite, and the inner wall of the tank body 1 is fixedly connected with a plurality of elastic expansion devices 5 along the circumferential direction, and the movable end of the elastic expansion device 5 is fixedly connected with a frame body 7, and the frame body 7 faces the direction of the rotating ring. The side is fixedly connected with a second magnet 8, and the magnetic south pole and the magnetic north pole of the adjacent second magnet 8 are in opposite direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com