Method for sterilizing low-acid fruit and vegetable juice by cooperation of freezing pretreatment and ultrahigh pressure

A freezing pretreatment and ultra-high pressure technology, applied in ultra-high pressure food processing, food freezing, food science and other directions, can solve the problems of limited sterilization ability, limited sterilization ability of spore-forming bacteria, and difficulty in achieving commercial sterilization, and achieve sterilization effect. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

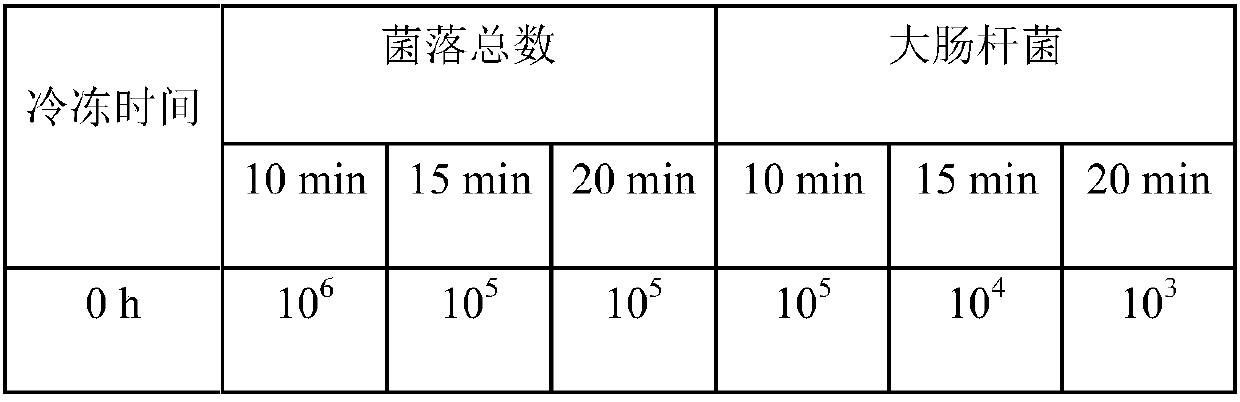

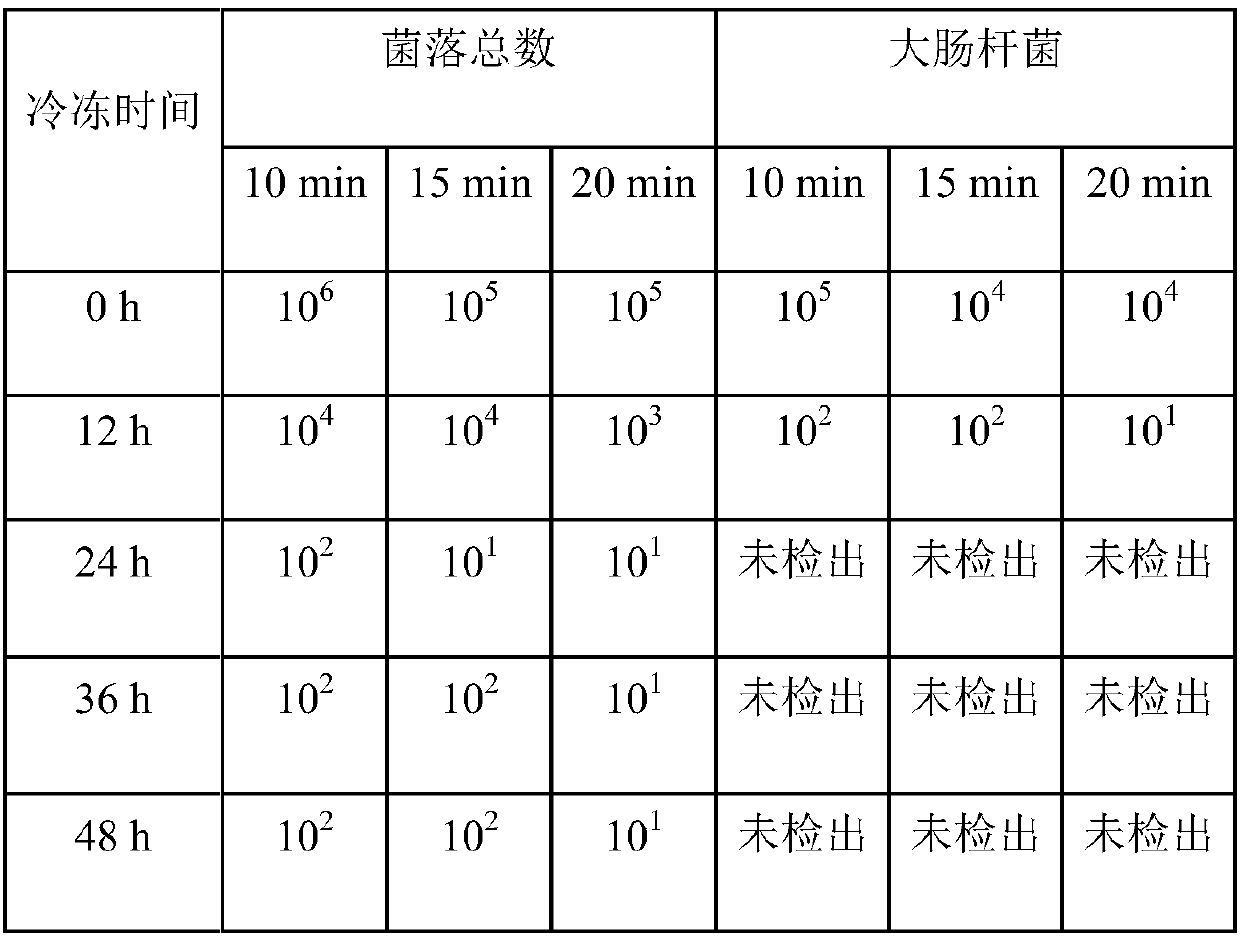

[0020] Squeeze the juice of cucumber, carrot and watermelon, then centrifuge at 10,000 rpm for 20 minutes and take the supernatant to obtain cucumber juice, carrot juice and watermelon juice. Inoculate the colonies separately so that the total number of fruit and vegetable juice colonies in Group 1 reaches 10 8 CFU / ml, so that the number of E. coli in the fruit and vegetable juice of group 2 reaches 10 7 CFU / ml. The two groups of fruit and vegetable juices after inoculation were frozen at -20°C for 0h (unfrozen), 12h, 24h, 36h and 48h, and then thawed at room temperature for 6 hours, respectively, using pressures of 400, 500, 600Mpa and 10 , 15, 20min dwell time of ultra-high pressure processing parameters processing. The ultra-high pressure treatment refers to transferring the vacuum packaging bag containing fruit and vegetable juice to a pressure container, and then filling compressed gas to a predetermined pressure; or directly filling the pressure container containing fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com