Integrated planar supercapacitor and preparation method thereof

A supercapacitor, planar technology, applied in the manufacture of hybrid/electric double layer capacitors, multiple hybrid/electric double layer capacitors, etc., can solve the problem of reducing device mass specific capacity, volume specific capacity, device integration, and unfavorable electronic components Integration, complex preparation process and other issues, to achieve the effect of adjustable capacity, wide applicability, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

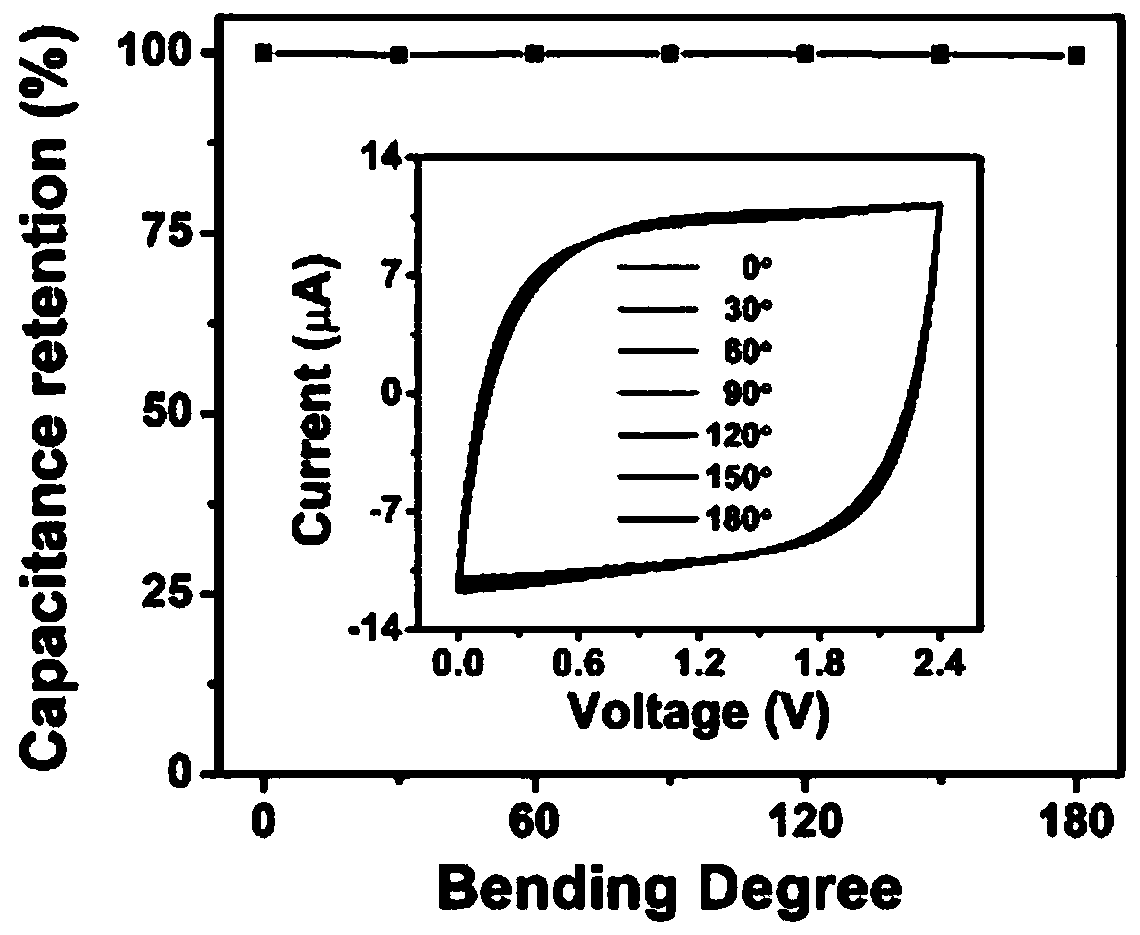

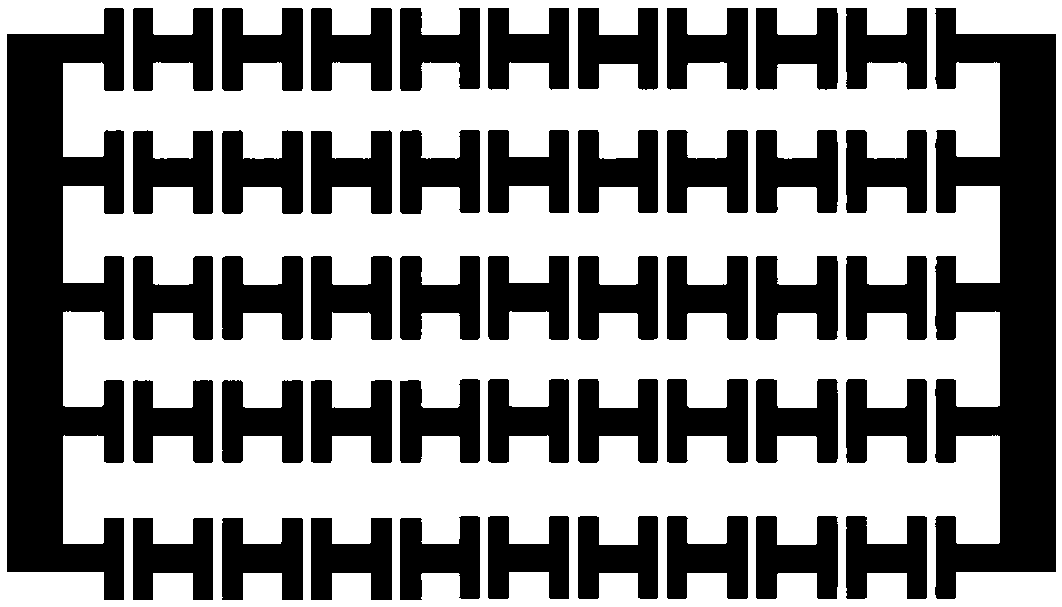

Embodiment 1

[0041] The intercalation-exfoliated graphene and conductive carbon black are fully mixed with a mass ratio of 8:2 to obtain a mixture of the two, and then the above mixture is dispersed in a bivalent ester dissolved in polyvinyl chloride vinyl acetate by ball milling, wherein the mixture The mass ratio of polyvinyl chloride vinyl acetate and dibasic acid ester is 1:1:9, and the resulting dispersion system is used as conductive ink for screen printing. Design the screen printing screen, the screen part is 3 concentric circular devices and the connectors in series between the devices, the diameter of the inner circle is 4mm, the diameter of the outer circle is 6.5mm, the distance between the inner and outer circles is 0.5mm, and the width of the connector is 2mm. Such as figure 1 shown. When screen printing, place PET about 5mm below the screen, apply conductive ink to the blank space at one end of the screen, and then use a scraper to scrape the ink to the other end of the scr...

Embodiment 2

[0044] The reduced graphene oxide and the conductive carbon black are fully mixed with a mass ratio of 7:3 to obtain a mixture of the two, and then the above mixture is dispersed in a bivalent ester dissolved in polyvinyl chloride vinyl acetate by a ball milling method, wherein the mixture, poly The mass ratio of vinyl chloride vinyl acetate and dibasic ester is 1:1:9, and the resulting dispersion system is used as conductive ink for screen printing. Design the screen printing screen, the screen part is 4 linear devices and the connectors in series between the devices, the length of a single electrode of the linear device is 1cm, the width is 0.6mm, the spacing is 1mm, the length of the connector is 6mm, and the width is 2mm. When screen printing, place A4 paper about 5mm below the screen, apply conductive ink to the blank space at one end of the screen, and then use a scraper to scrape the ink to the other end of the screen at a speed of about 3cm / s, during which the ink is s...

Embodiment 3

[0047] Mix multi-walled carbon nanotubes and polyvinylidene fluoride at a mass ratio of 9:1 to obtain a mixture of the two, disperse the above mixture in N-methylpyrrolidone, and the mass ratio of the mixture to N-methylpyrrolidone is 1:5, The resulting dispersion was used as a screen printed conductive ink. Design the screen printing screen, the screen part is 4 linear devices and the parallel connection between the devices, the length of a single electrode of the linear device is 1cm, the width is 0.6mm, the spacing is 1mm, the length of the connector is 1cm, and the width is 3mm. When screen printing, place the glass plate about 5mm below the screen, apply conductive ink to the blank space at one end of the screen, and then use a scraper to scrape the ink to the other end of the screen at a speed of about 3cm / s, during which the ink is squeezed Deposit on the glass plate by pressing through the mesh of the screen plate, then dry the glass plate at 100°C for 12 hours, and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com