Motor driving testing device with microsecond-grade real-time control data monitoring function

A real-time control and data monitoring technology, which is applied in the direction of motor generator testing, measuring devices, measuring electricity, etc., can solve the problems of increased difficulty in fault diagnosis, inability to store data, and inability to obtain motor data, etc., to achieve a beneficial effect for fault diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. The present invention includes but is not limited to the following examples.

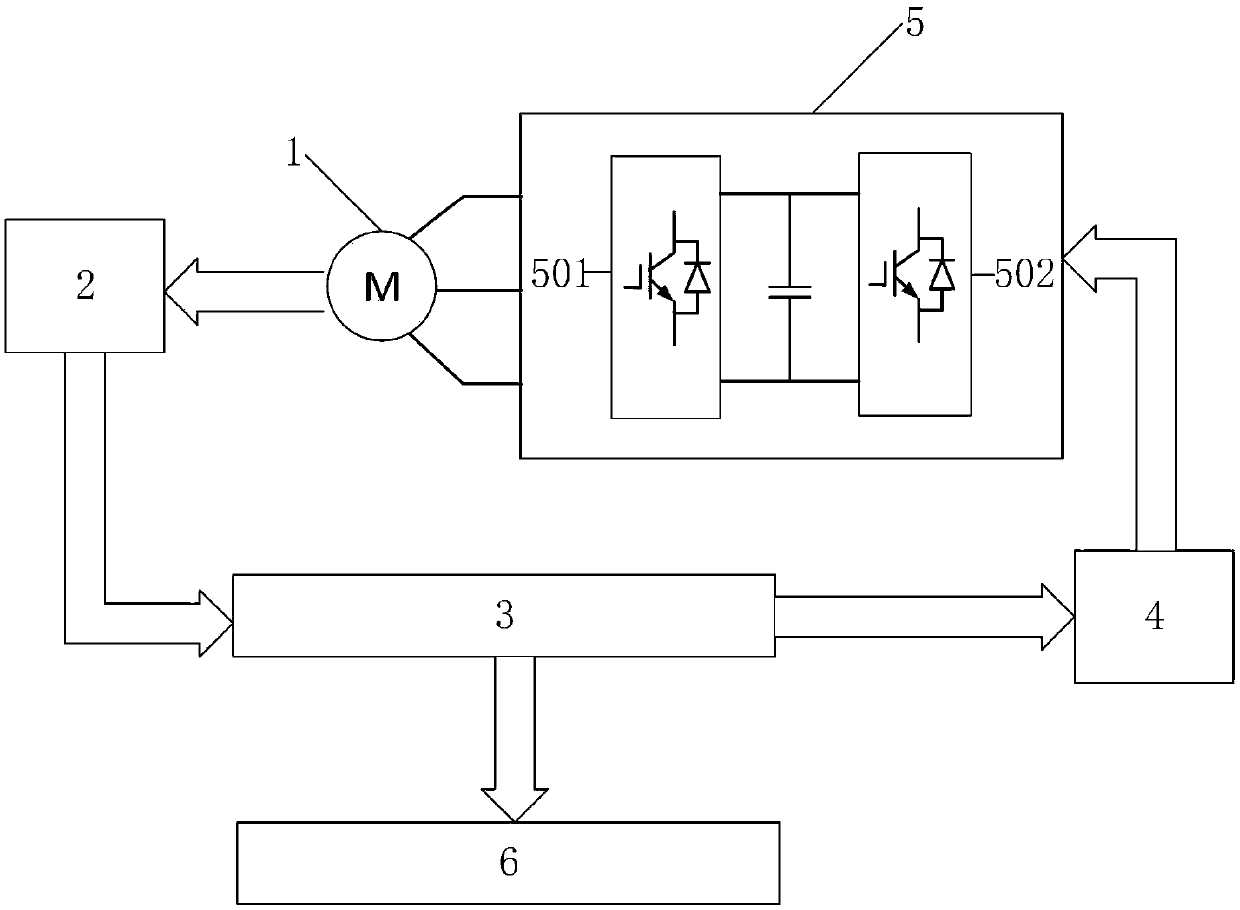

[0029] like figure 1 As shown, the present invention provides a motor drive test device with microsecond-level real-time control data monitoring, including: a motor under test 1, a data processor 2, a controller 3, a driver 4, a dual PWM topology unit 5, and a control center 6;

[0030] Wherein, the data processor 2, the controller 3, the driver 4 and the dual PWM topology unit 5 are serially connected in series, and the controller 3 is also connected to the control center 6; the data processor 2 and the dual PWM topology unit 5 are respectively connected to the motor 1 under test;

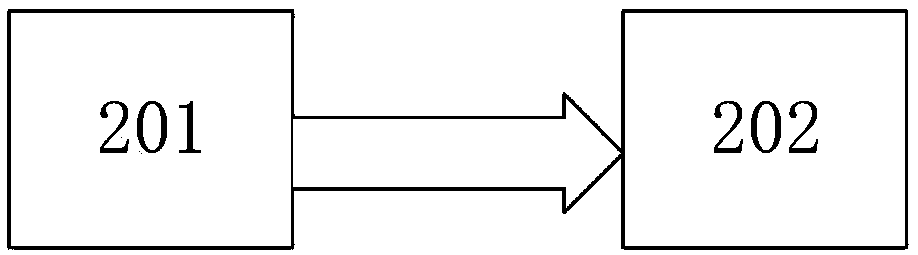

[0031] The composition of described data processor 2 is as figure 2 As shown, it includes a sampling module 201 and a first operational amplification module 202 . The sampling module 201 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com