A detection device and method for environmental test stability of a camera device

A technology for camera devices and environmental testing, which is used in measurement devices, optical instrument testing, machine/structural component testing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

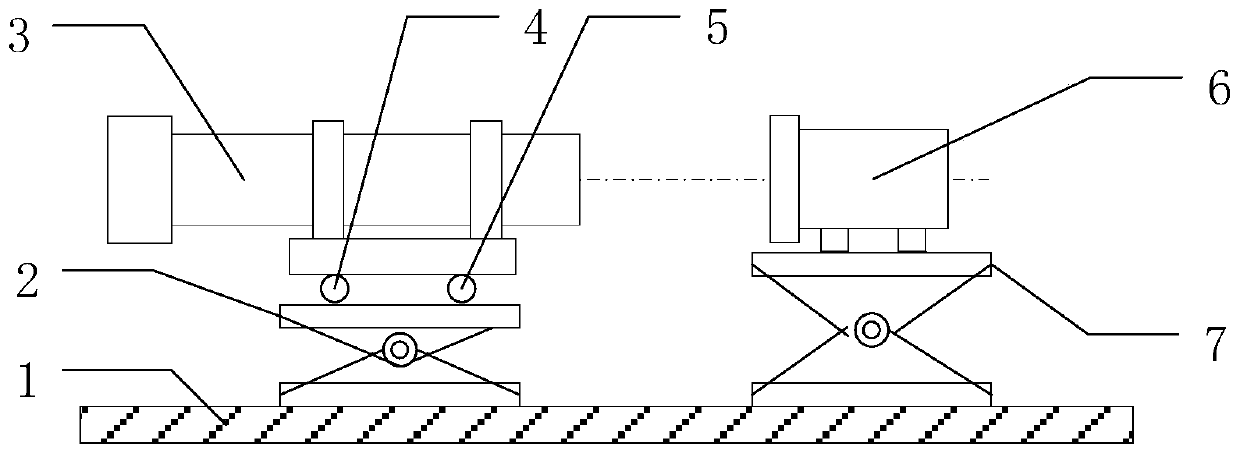

[0039] A detection device for the environmental test stability of an imaging device of the present invention, such as figure 1 As shown, it includes an optical table 1, a shear frame I2 and a shear frame II7 are installed at intervals on the optical table 1, a PSD autocollimator 3 is placed on the shear frame I2, and a camera device 6 is placed on the shear frame II7 to adjust the shear The heights of the frame I2 and the shear frame II7 control the optical axis of the PSD autocollimator 3 to be equal to the optical axis of the camera device 6 .

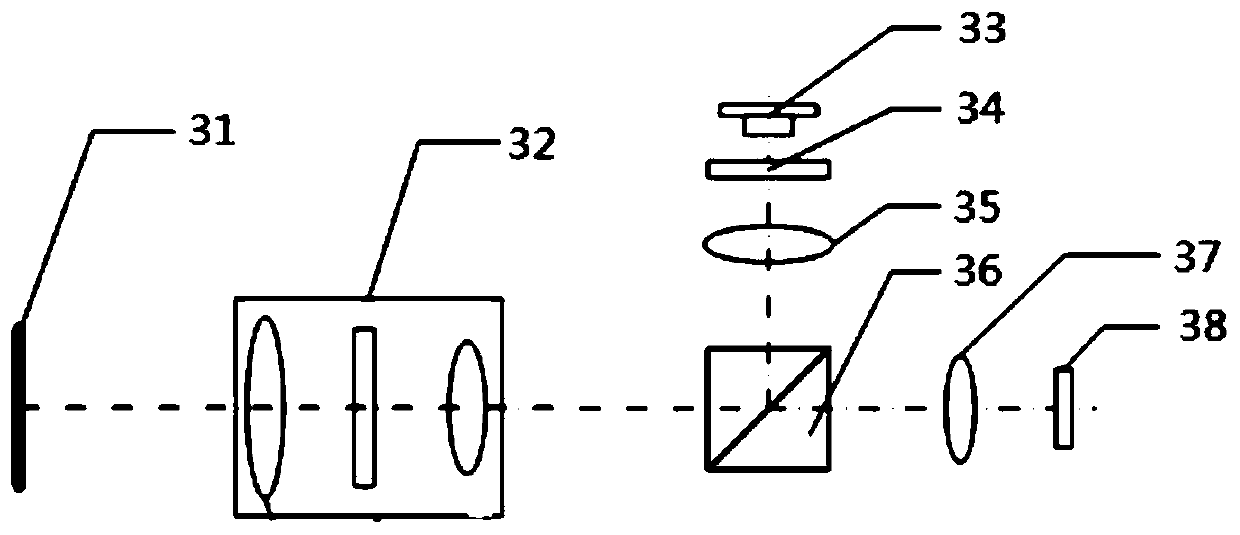

[0040] Such as figure 2 As shown, the PSD autocollimator 3 includes a target reflection surface 31, a telescopic lens group 32, a light source 33, a focusing lens 35, a dichroic prism 36, a converging lens 37 and a PSD chip 38, and the focal point of the converging lens 37 and the light source 33 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com