Surface drag reduction simulation testing device for underwater vehicle under deep-sea high-pressure environment

A technology for underwater vehicles and high-pressure environments. It is applied in the direction of measuring devices, testing of machines/structural components, and instruments. It can solve problems such as the inability to test the drag reduction effect of deep-water vehicles, and achieve simple structure, easy operation, and experimental results. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

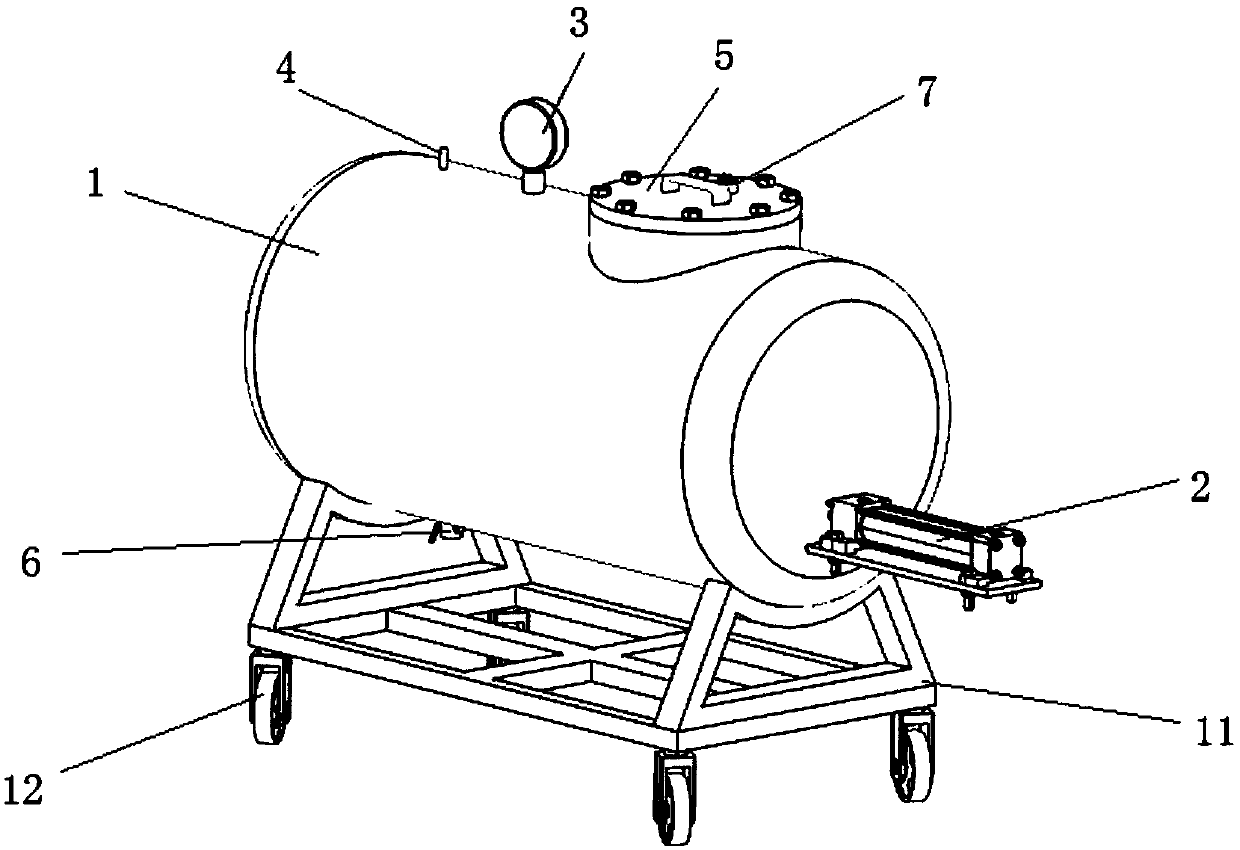

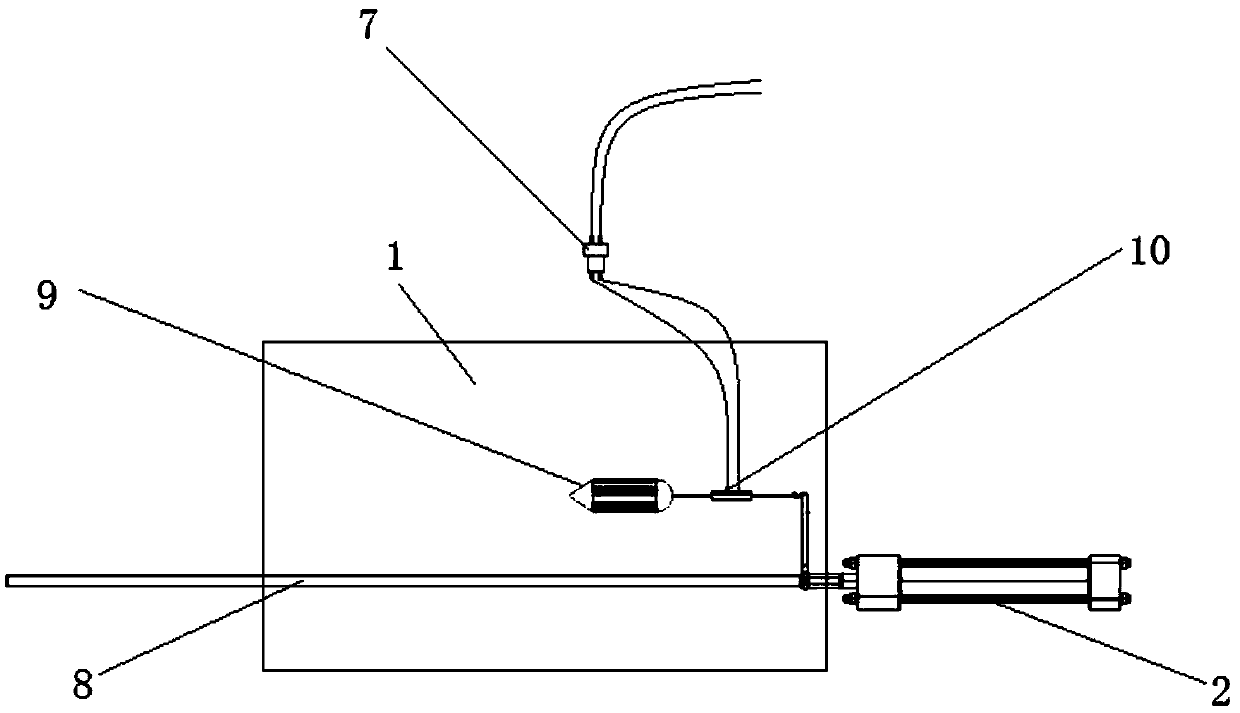

[0021] like figure 1 As shown, the surface drag reduction simulation test device of the underwater vehicle under the deep-sea high-pressure environment of the present invention includes a high-pressure sealed cabin 1 and a hydraulic cylinder 2;

[0022] The high-pressure airtight chamber is a horizontal cylindrical shape. Compared with the cuboid shape, the cylindrical shape can withstand higher pressure. Compared with the ellipsoid shape, the cylindrical shape can ensure that the cross-sectional area of each place is the same to ensure that the underwater vehicle model During the movement, each place receives the same environmental pressure; the top of the high-pressure sealed cabin is provided with a pressure gauge 3, a water injection pressure port 4 and a sealing cover 5, and the bottom is provided with a drainage and pressure relief port 6, and the sealing cover pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com