Absorption/contraction mixing circulatory system for independent mechanical cooling

A mechanical cooling and circulation system technology, applied in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems of system heating capacity and COP decrease, compressor discharge temperature rise, compressor discharge temperature high, etc. Achieve the effect of improving system heating COP and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

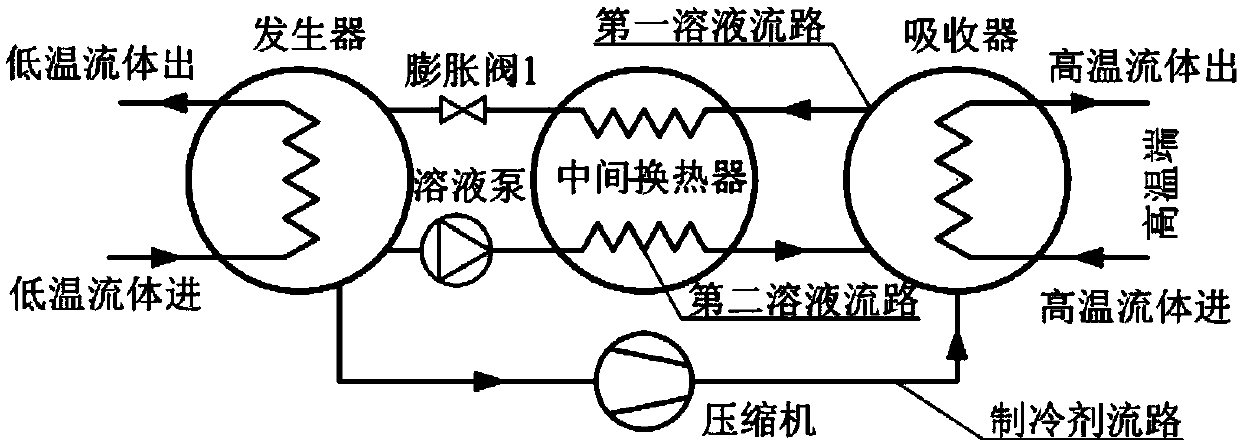

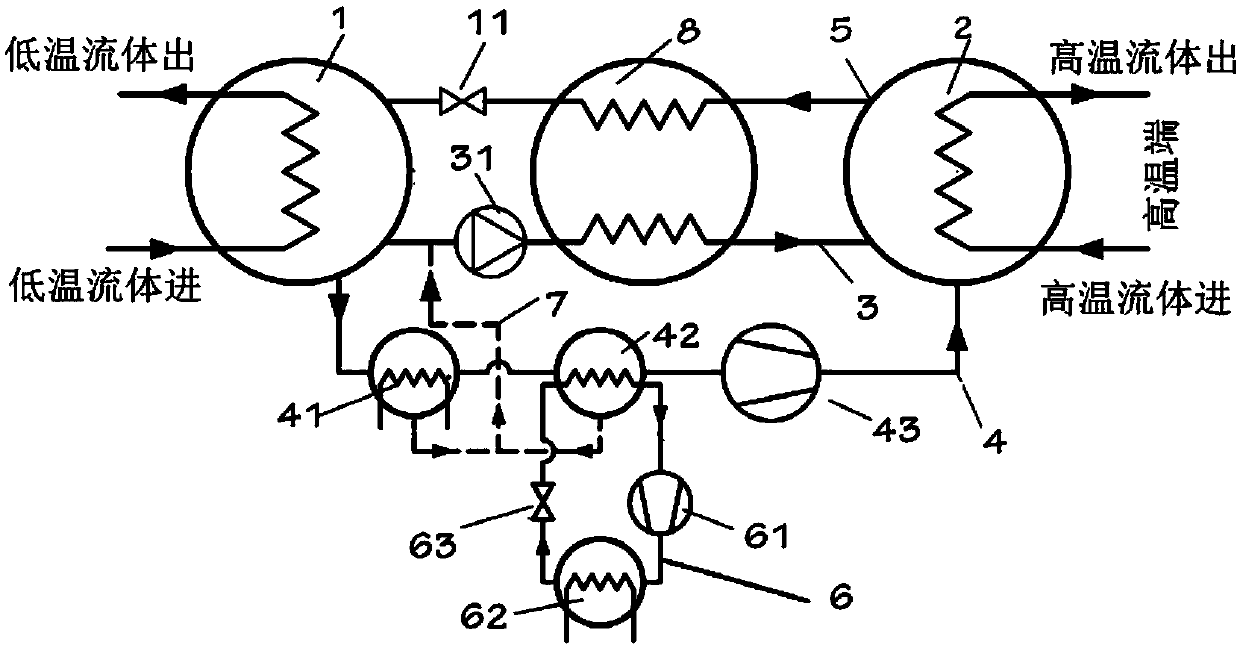

[0020] Separate mechanically cooled absorption / compression hybrid cycle comprising generator 1, absorber 2 and vapor compression cycle 6, see figure 2 .

[0021] The generator 1 includes the first heat exchange channel of the generator and the second heat exchange channel of the generator, the absorber 2 includes the first heat exchange channel of the absorber and the second heat exchange channel of the absorber, and the first heat exchange channel of the generator The heat exchange channel is used to absorb heat from the low temperature end and transfer the heat to the second heat exchange channel of the absorber, and a second solution flow path is provided between the second heat exchange channel of the generator and the second heat exchange channel of the absorber 3. Refrigerant flow path 4 and first solution flow path 5, see figure 2 , the second heat exchange channel of the generator is used for the evaporation of the concentrated refrigerant solution to generate a dil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com