Air channel switch valve and grinding machine

An on-off valve and gas path technology, applied in the field of gas path switch valve and grinder, can solve problems such as inconvenient opening adjustment, manual operation of the gas path switch valve to open or close, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

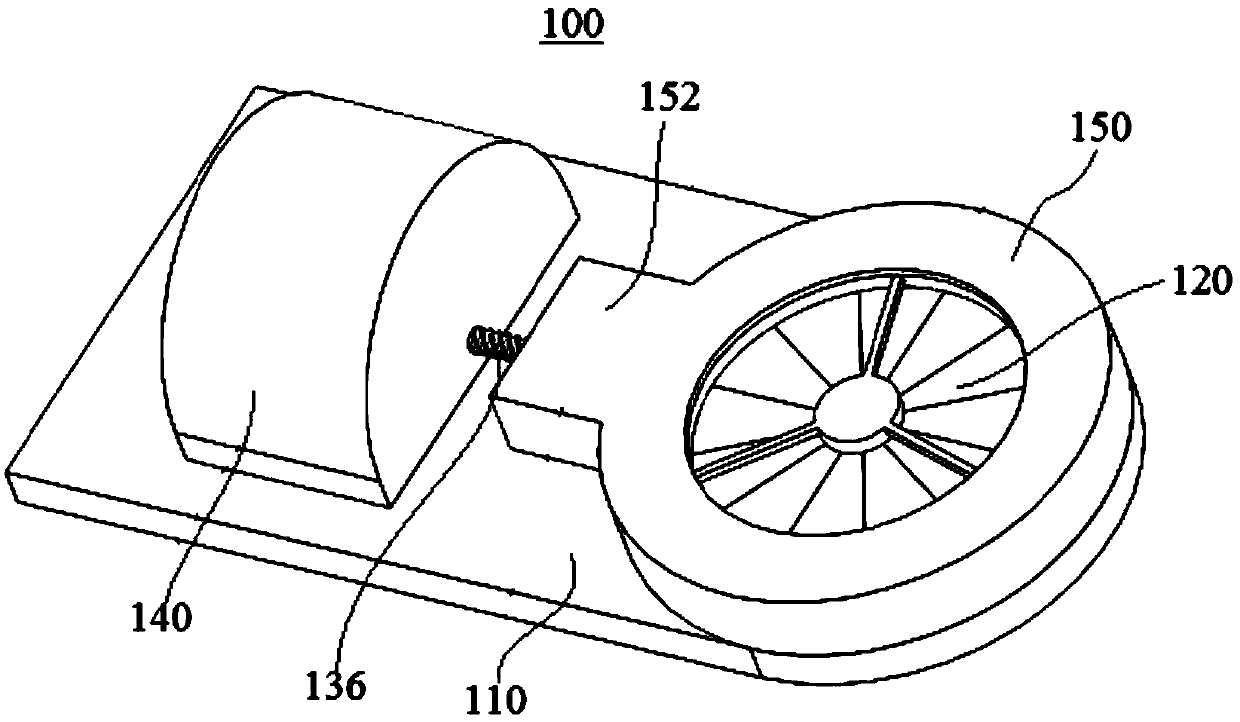

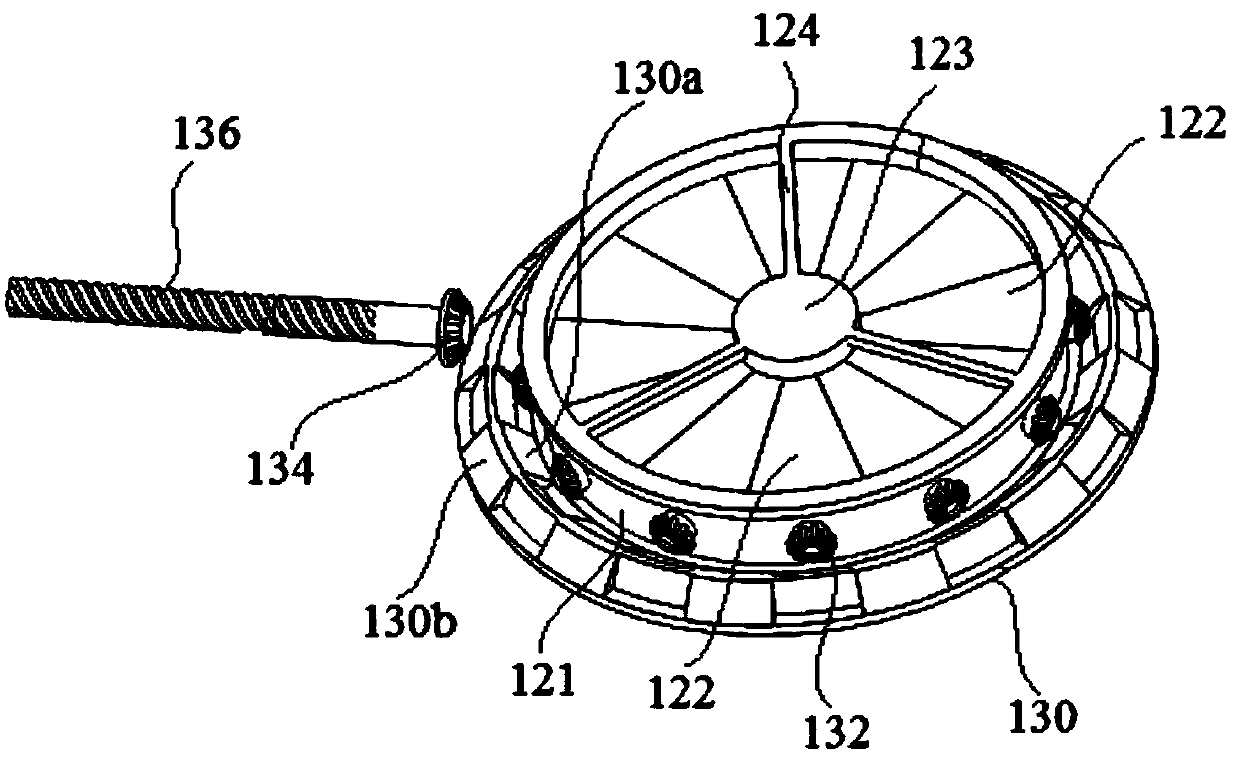

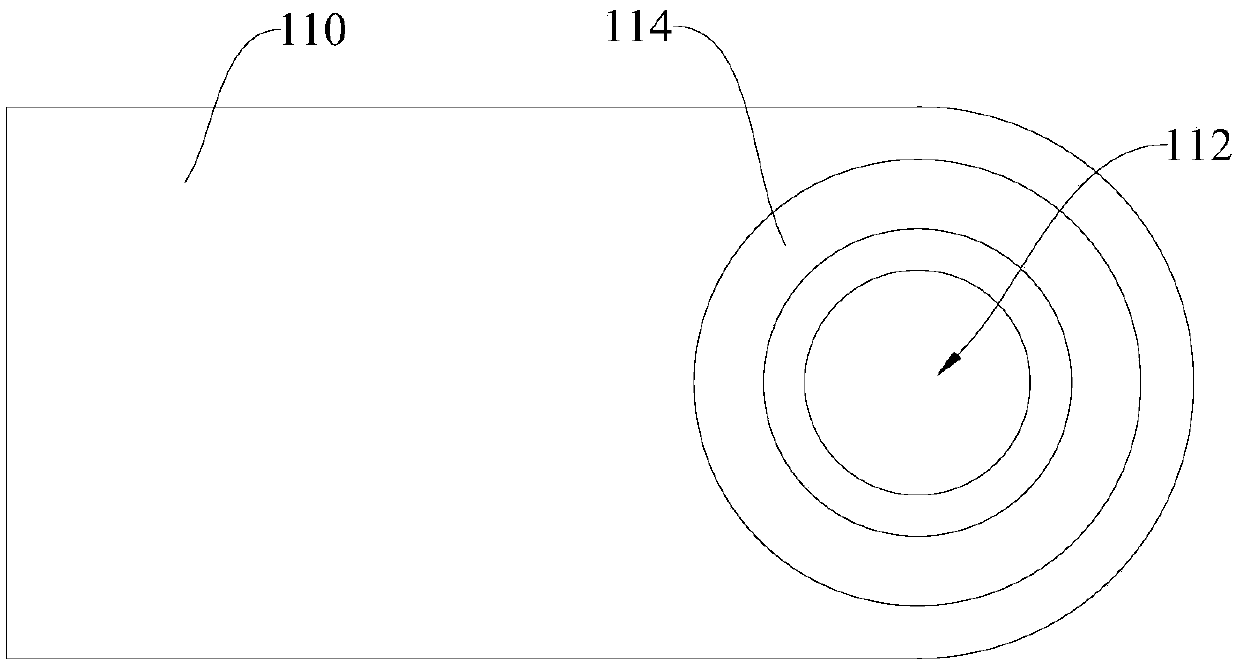

[0036] figure 1 It is an overall schematic diagram of the gas circuit switch valve 100 in the embodiment of the present invention; figure 2 It is a schematic diagram of cooperation between the switch structure 120 and the transmission assembly in the embodiment of the present invention; image 3 It is a schematic diagram of the seat body 110 in the embodiment of the present invention. Please refer to Figure 1 to Figure 3 , this embodiment provides an air circuit switch valve 100, which includes:

[0037] The seat body 110 has a vent hole 112 on the seat body 110;

[0038] The switch structure 120 arranged at one end of the air hole 112, the switch structure 120 includes a frame body 121 arranged on the seat body 110 and a plurality of shutters 122 arranged in the frame body 121; the frame body 121 is arranged along the edge of the opening of one end of the air hole 112 , the frame body 121 and the vent hole 112 form an airflow flow path, and a plurality of installation h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com