Fine pressure control well cementing operation method

A fine and cementing technology, which is applied in earthwork drilling, wellbore/well components, sealing/isolation, etc., to achieve fine control of wellhead pressure, ensure downhole pressure, and improve cementing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

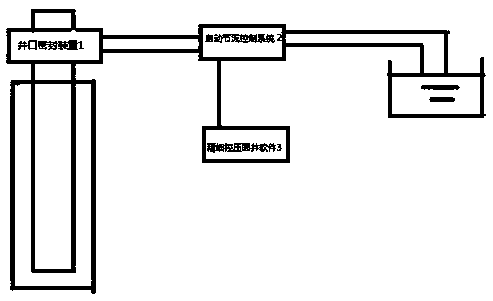

[0026] As shown in the figure, as the best embodiment of the present invention, its steps include:

[0027] Step 1: Prepare the wellhead sealing device matching the outer diameter of the running string;

[0028] Step 2: Use conventional cementing software to optimize the design of precise pressure-controlled cementing construction parameters to ensure that the bottom hole pressure is within the safe operating density window;

[0029] Step 3: Run the cementing string under pressure to the design well depth according to the design of fine pressure-controlled cementing, turn on the pump to circulate exhaust, and adjust the density of the drilling fluid in the wellbore to the design value;

[0030] Step 4: After the density of the drilling fluid in the wellbore is stable, stop the pump, add pressure at the wellhead through the fine pressure control surface equipment to ensure the stability of the downhole pressure, and connect to the cementing construction equipment;

[0031] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com