High-liquid limit soil reinforcement roadbed filling structure and method

A high liquid limit soil and filling technology, applied in roads, roads, buildings, etc., can solve the problems of poor stability, low strength, high water content, etc., and achieve improved modulus of resilience, obvious skeleton effect, and soil permeability enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In this embodiment, the application section is Wanyang Expressway K110+200 to K110+500, the maximum filling height of this section is 7.1m, and the minimum is 6.2m.

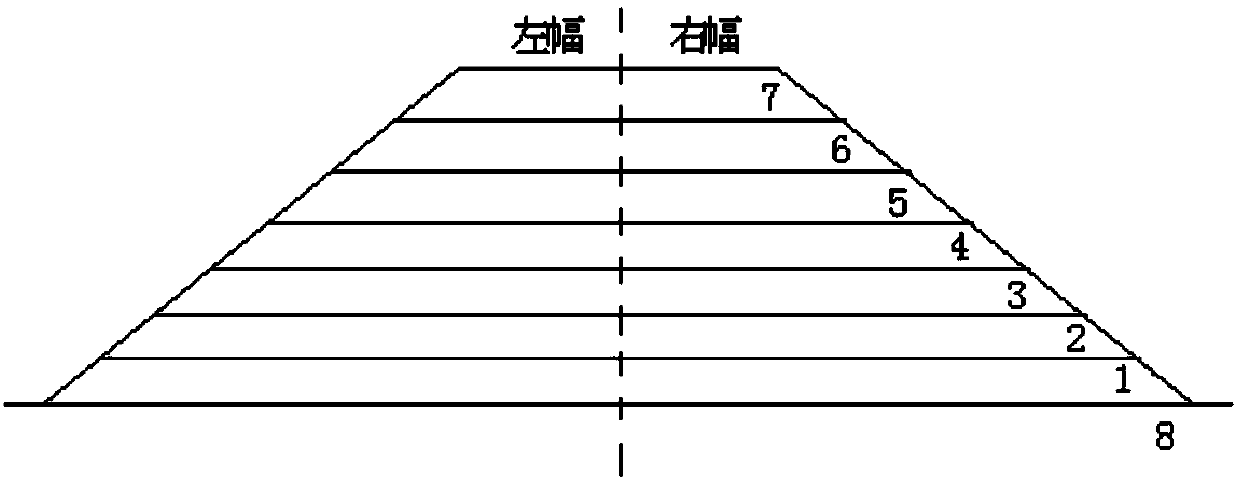

[0025] like figure 1 , 2 As shown, a high liquid limit soil reinforced roadbed filling structure, the filling structure includes 93 areas, 94 areas and 96 areas arranged in sequence from bottom to top, and each area is divided into a left side and a right side by the center line of the cross section. ; Described 94 area includes 94-1 layer 1, 94-2 layer 2 and 94-3 layer 3 arranged sequentially from bottom to top, and described 96 area includes 96-1 layer 4, 96-2 arranged sequentially from bottom to top Layer 5, 96-3 Layer 6 and 96-4 Layer 7.

[0026] The thickness of the 93 area (8) is 5100mm, the thickness of each layer in the 94 area is 94-1 layer (1) 300mm, 94-2 layer (2) 200mm, 94-3 layer (3) 200mm, the said The thickness of each layer in the 96 area is 96-1 layer (4) 200mm, 96-2 layer (5) 200mm, 96...

Embodiment 2

[0030] Using a high liquid limit soil reinforced roadbed filling method of the filling structure described in Example 1, the construction road section is divided into sections and layers to form a roadbed filling structure. Liquid-limited soil or low-liquid-limited soil mixed with different proportions of gravel or cement at the same time, including the following steps:

[0031] S1. Divide the construction road section into zone-layer structure to form a subgrade filling structure. The filling structure includes zone 93, zone 94 and zone 96 arranged in sequence from bottom to top, and each zone is divided into the left side by the center line of the cross section. and the right panel; the 94 area includes 94-1 layer 1, 94-2 layer 2 and 94-3 layer 3 arranged in sequence from bottom to top, and the 96 area includes 96-1 layer 4, 96-1 layer 4, 96-2 floor 5, 96-3 floor 6 and 96-4 floor 7;

[0032] S2. Fill each layer of each location, and the specific filling composition of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com