Anisotropic conductive tape and preparation method thereof

A technology of anisotropic conduction and manufacturing method, which is applied in the direction of conductive adhesive, printed circuit manufacturing, circuit, etc., can solve the problems of increasing bump area and affecting the realization of driving lines, and achieve the design of multiple driving lines and improve the resolution rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

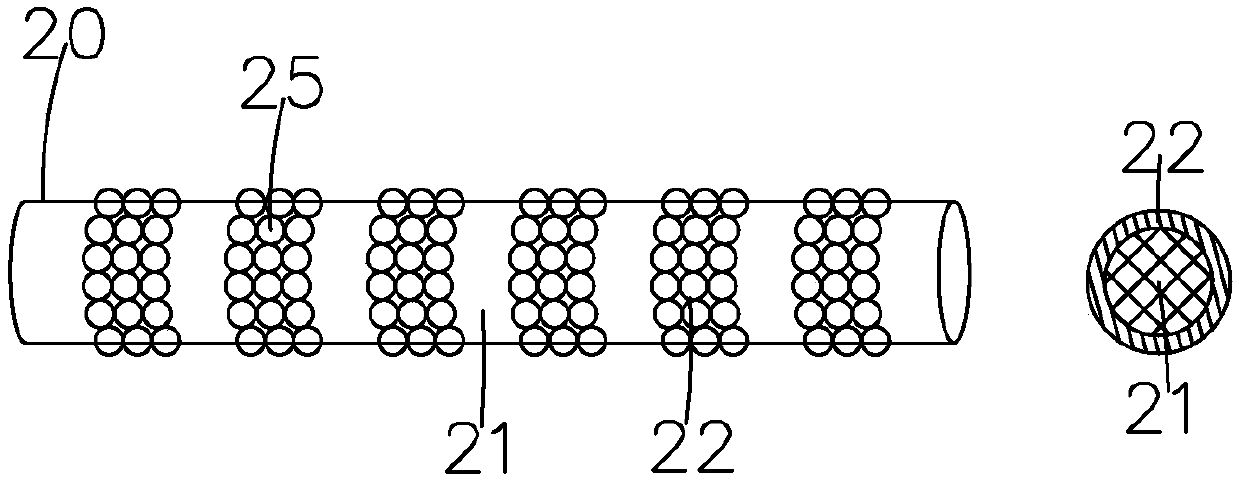

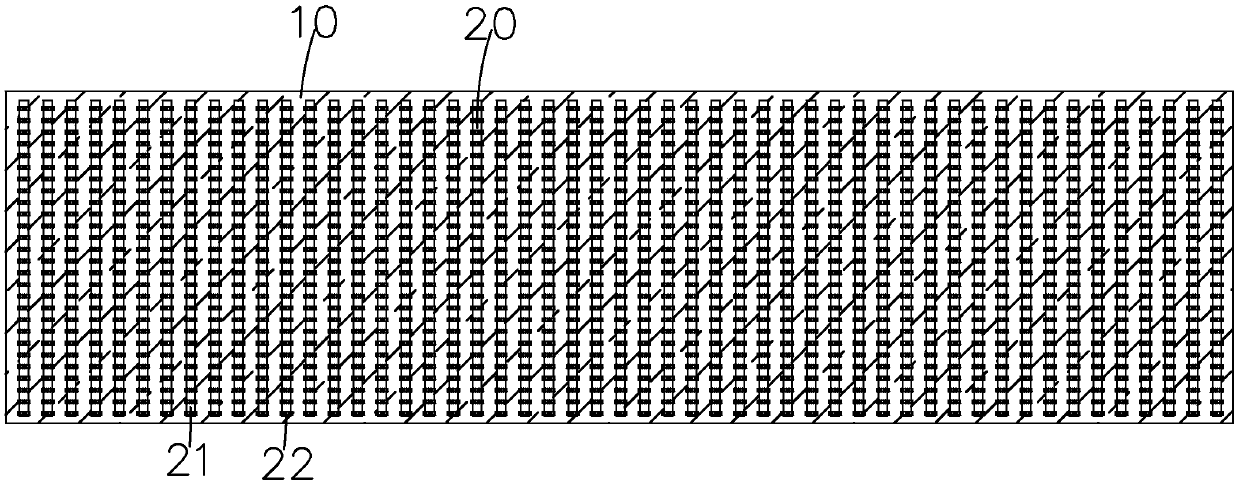

[0059] Such as Figure 8 As shown, based on the above-mentioned anisotropic conductive tape, the present invention also provides a method for making an anisotropic conductive tape. The first embodiment of the method for making an anisotropic conductive tape of the present invention specifically includes the following steps:

[0060] Step S1 , making a plurality of composite fibers 20 , and periodically arranging the plurality of composite fibers 20 .

[0061] Wherein, each composite fiber 20 includes an electrically insulating fiber 21 and a plurality of conductive rings 22 that are periodically arranged along the axial direction of the electrically insulating fiber 21 and are wrapped around the electrically insulating fiber 21; A plurality of conductive particles 25 adsorbed and co-encircled on the electrically insulating fibers.

[0062] Specifically, the shape of the conductive particles 25 may be other shapes such as spherical, cubic, or conical.

[0063] Specifically, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com