Straw briquetting machine

A straw briquetting machine and extrusion disc technology, which is applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problems of increasing labor costs, reducing work efficiency, and being inconsistent with the interests of enterprises, reducing impurities, The effect of sufficient and effective raw materials and full and effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

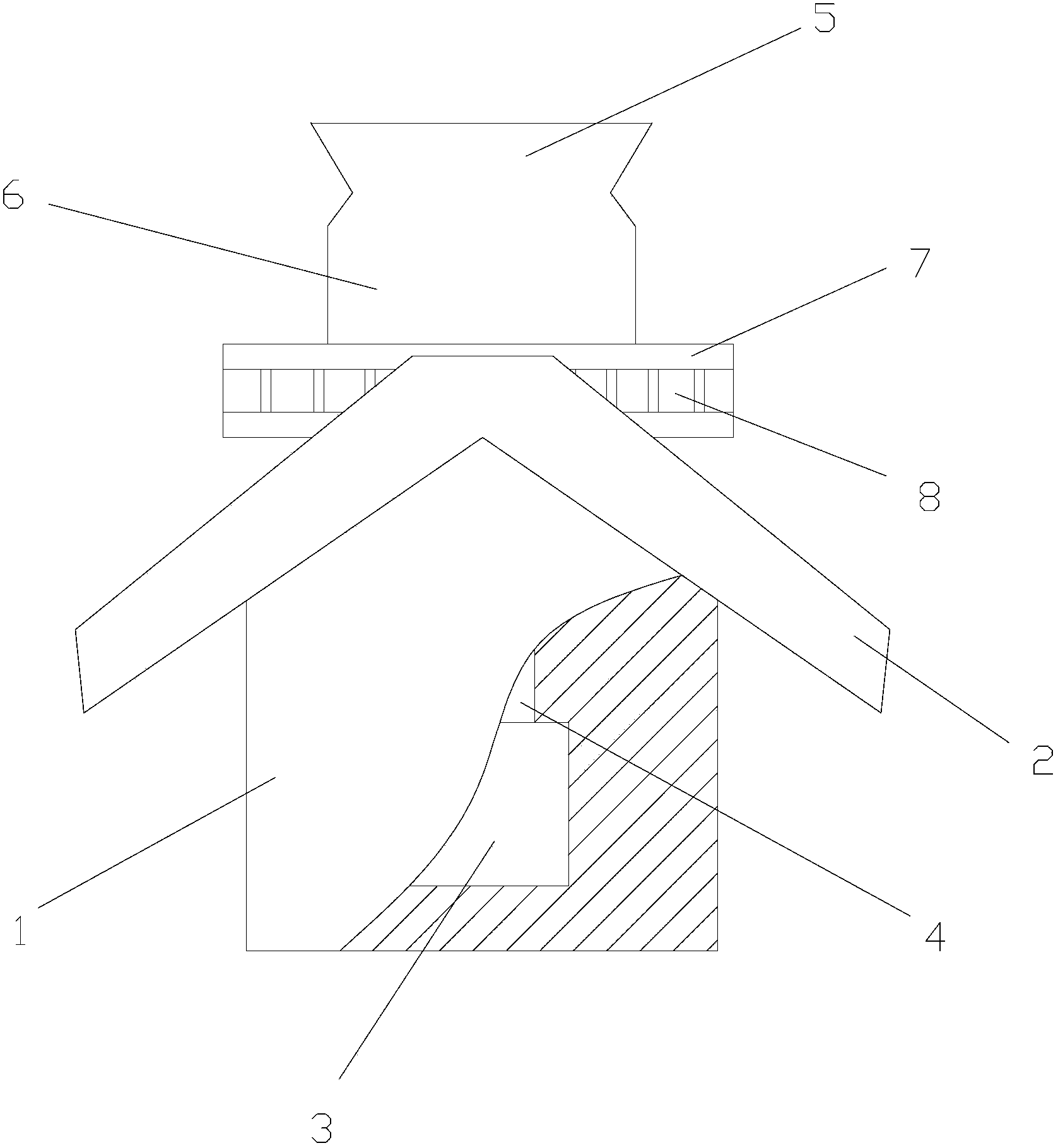

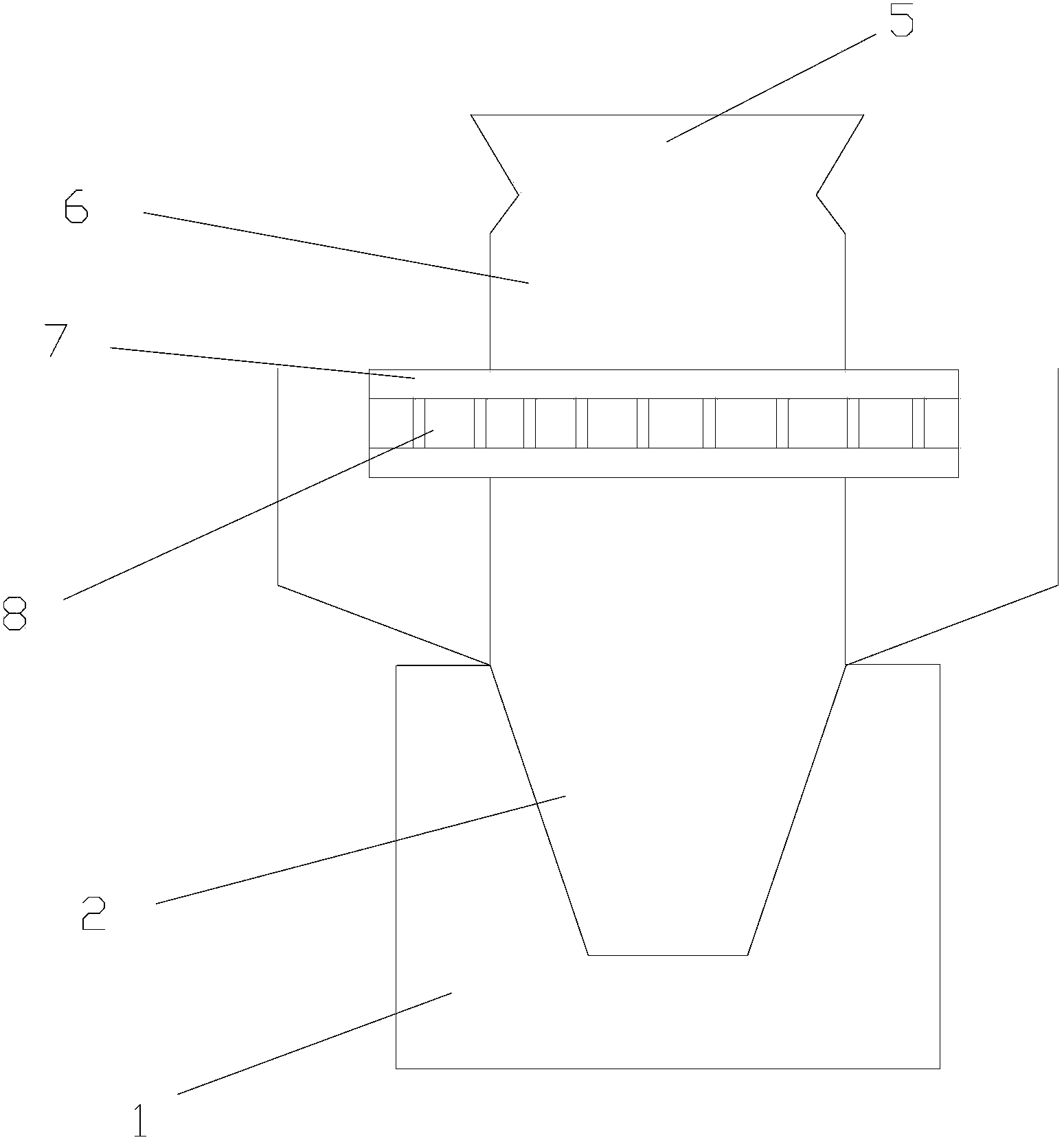

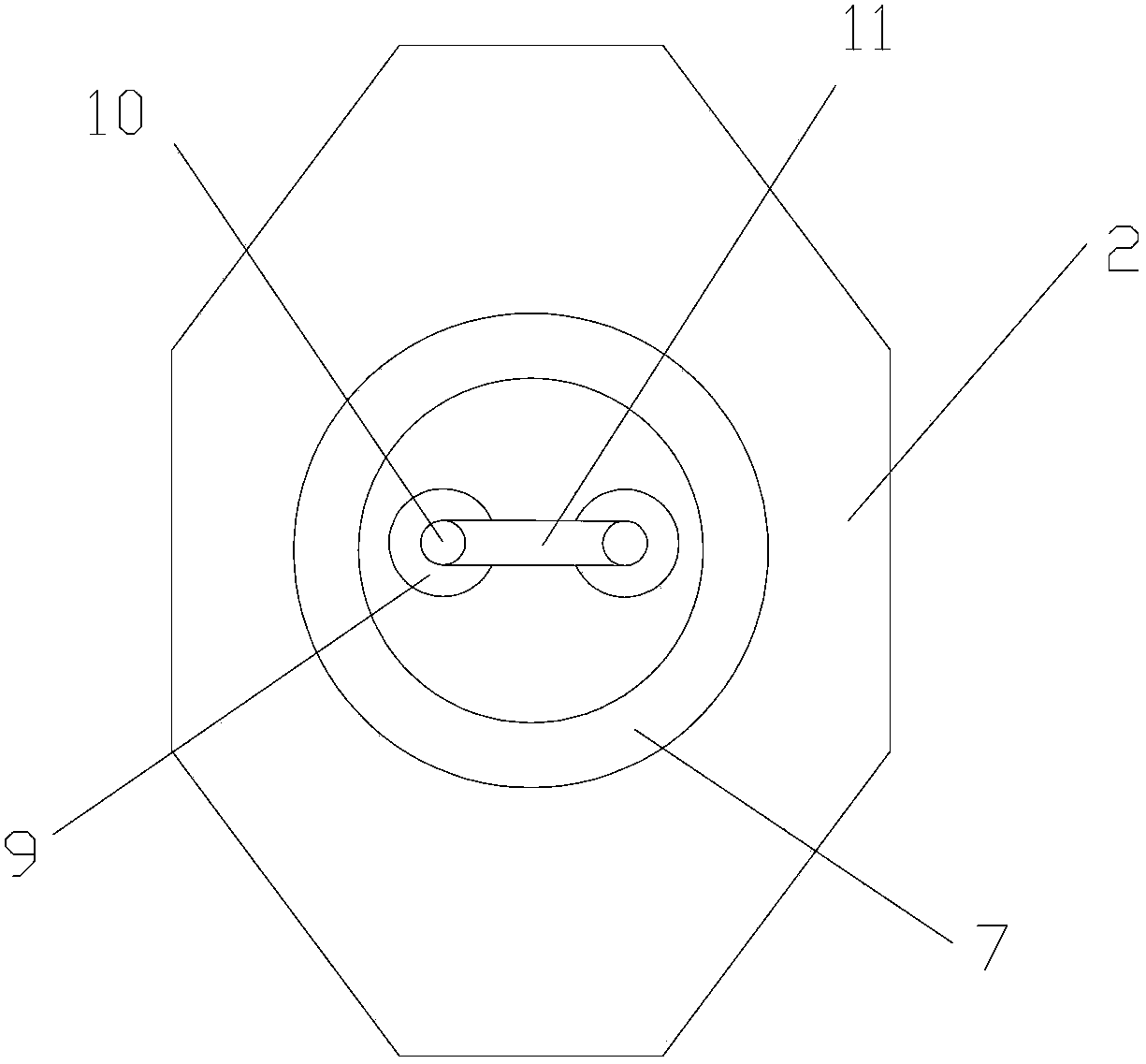

[0019] As shown in the picture, figure 2 , image 3 As shown, a straw briquetting machine includes a base 1 and a silo 6 , and the base 1 is provided with a motor 3 and a transmission shaft 4 . The top of the silo 6 is provided with a material inlet 5 . A disc 7 is arranged between the silo 6 and the base 1 , and rectangular discharge openings 8 are evenly distributed on the side of the disc 7 . The outer side of the disc 7 is provided with a discharge slideway 2, the top disc 7 of the discharge slideway 2 is of the same height, and the bottom extends to the base 1, and the width of the discharge slideway 2 gradually decreases from the top to the bottom ; The silo 6 is provided with no less than two extruding disks 9, and the top of any extruding disk 9 is provided with a cylindrical protrusion 10, and the cylindrical protrusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com