Antibacterial polystyrene composite material and preparation method and evaluation method thereof

A technology of polystyrene and composite materials, which is applied in the direction of testing the strength of materials, analyzing materials, and instruments using a single impact force to achieve the effects of enhanced overall dispersibility and bonding, excellent antibacterial effect, and high comprehensive performance.

Inactive Publication Date: 2019-04-16

TIANJIN KINGFA NEW MATERIAL

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the reports on antibacterial materials focus on polypropylene materials, but there is still a gap in research and development of antibacterial materials based on polystyrene materials

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-4

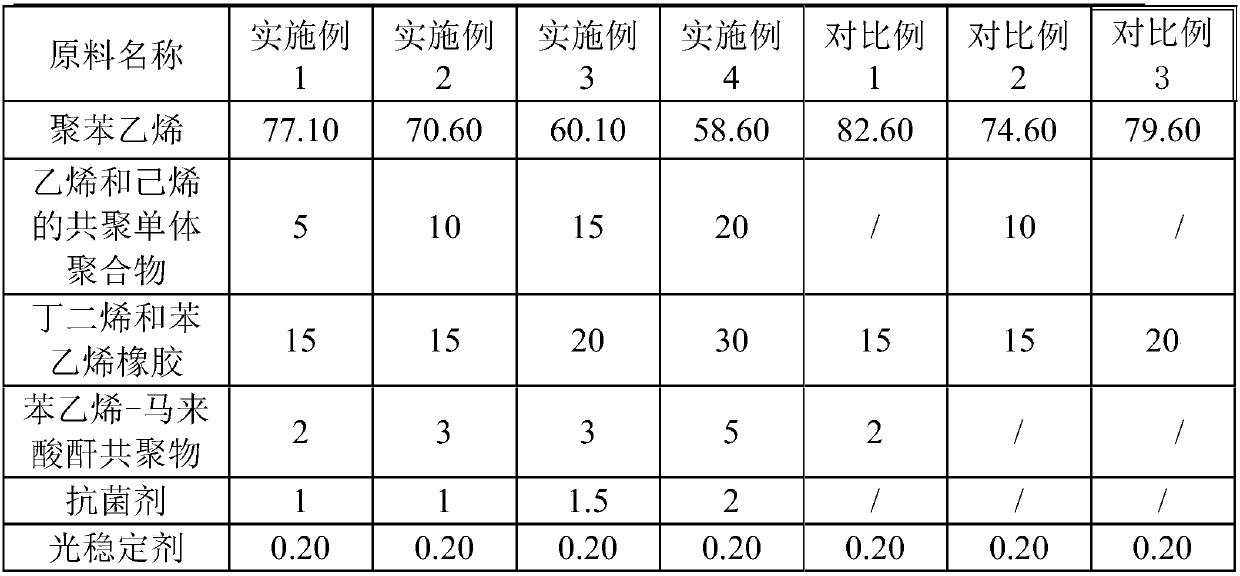

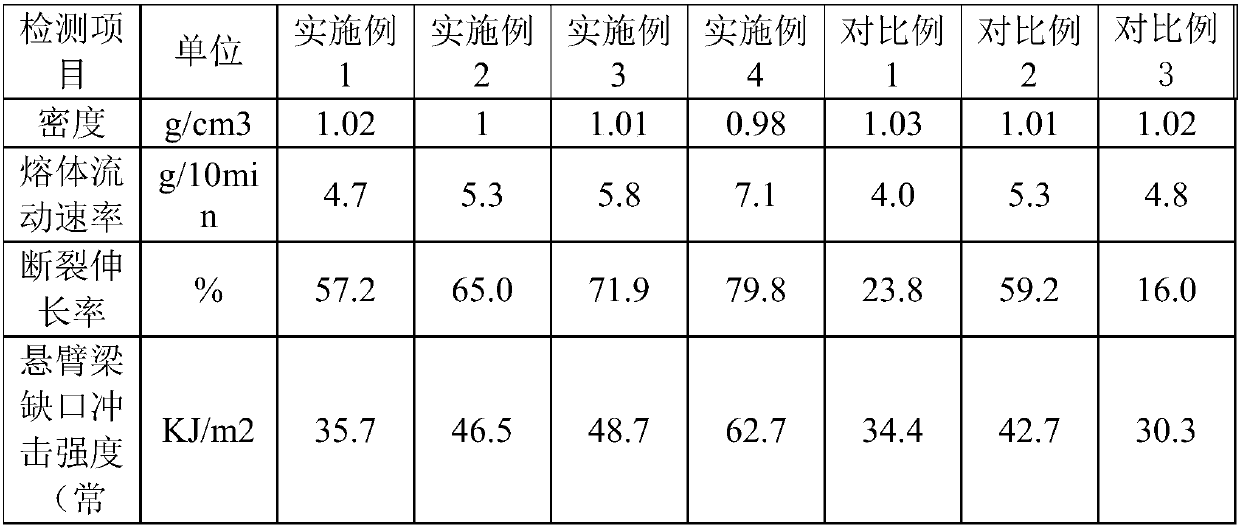

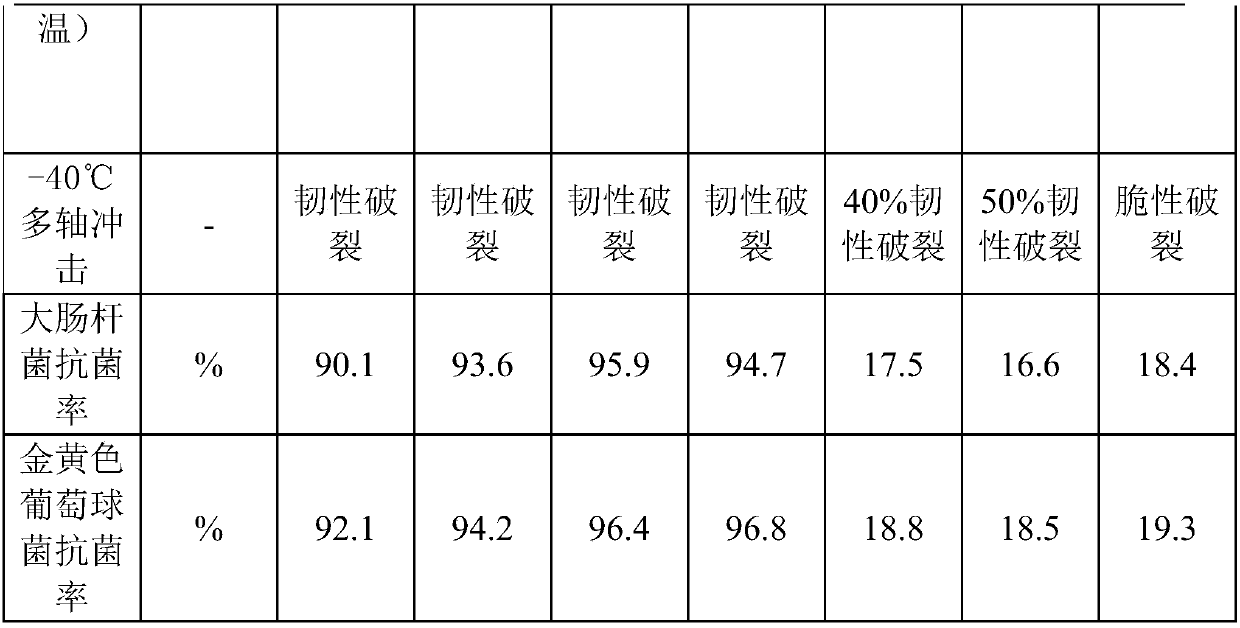

[0036] Embodiment 1-4, comparative example 1-2

[0037] A kind of composition, its raw material formula is as shown in table 1, table 2, and its preparation method may further comprise the steps:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides an antibacterial polystyrene composite material and a preparation method and evaluation method thereof. The antibacterial polystyrene composite material comprises, by weight, 42-85 parts of polystyrene, 15-30 parts of a styrene-butadiene-styrene block copolymer, 2-10 parts of a styrene-maleic anhydride copolymer, 5-20 parts of an ethylene and hexane comonomer polymer, 0.5-2parts of a photocatalyst antibacterial agent and silver inorganic antibacterial agent compound, and 0.2-1 part of an antioxidant. The antibacterial polystyrene composite material and the preparation method and evaluation method thereof are provided to develop the antibacterial polystyrene composite material which can meet the multi-axial impact test standard.

Description

technical field [0001] The invention belongs to the field of modified plastics, and in particular relates to an antibacterial polystyrene composite material, a preparation method and an evaluation method thereof. Background technique [0002] Polystyrene is the third largest variety of general-purpose plastics. It has the advantages of transparency, good formability, good rigidity, easy dyeing, low hygroscopicity and low price. It is used in packaging, electronics, construction, automotive appliances, instruments, daily necessities and toys. and other industries have been widely used. But polystyrene is brittle and has low impact strength. Therefore, increasing its toughness has always been an important topic of PS modification. [0003] However, the disadvantage of the polystyrene composite materials disclosed in the prior art is that no satisfactory combination of impact toughness and good ductility is obtained, and the polystyrene compositions disclosed in the prior art...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L51/04C08L9/06C08L35/06C08L23/08C08K3/015C08K3/22G01N3/30

CPCC08K2003/2241C08L51/04C08L2205/035G01N3/30G01N2203/001G01N2203/0228C08L9/06C08L35/06C08L23/0815C08K3/015C08K3/22

Inventor 肖华明宋晓辉孙超正郝垠龙

Owner TIANJIN KINGFA NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com