Preparing method and application of sugarcane-leaf hydrophobic modification nanocellulose

A nanocellulose, hydrophobic modification technology, applied in separation methods, chemical instruments and methods, foam dispersion/prevention, etc., to achieve the effect of broadening the scope of comprehensive utilization and reducing the amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Chapter 1 Preparation and Properties of Sugarcane Leaf Cellulose

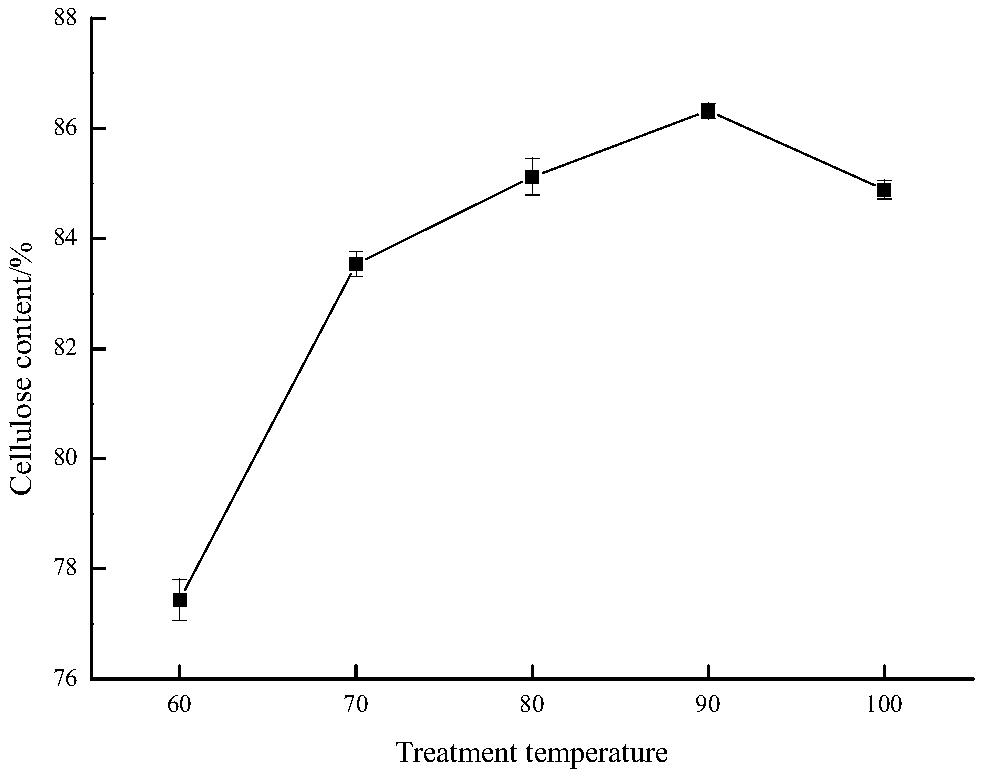

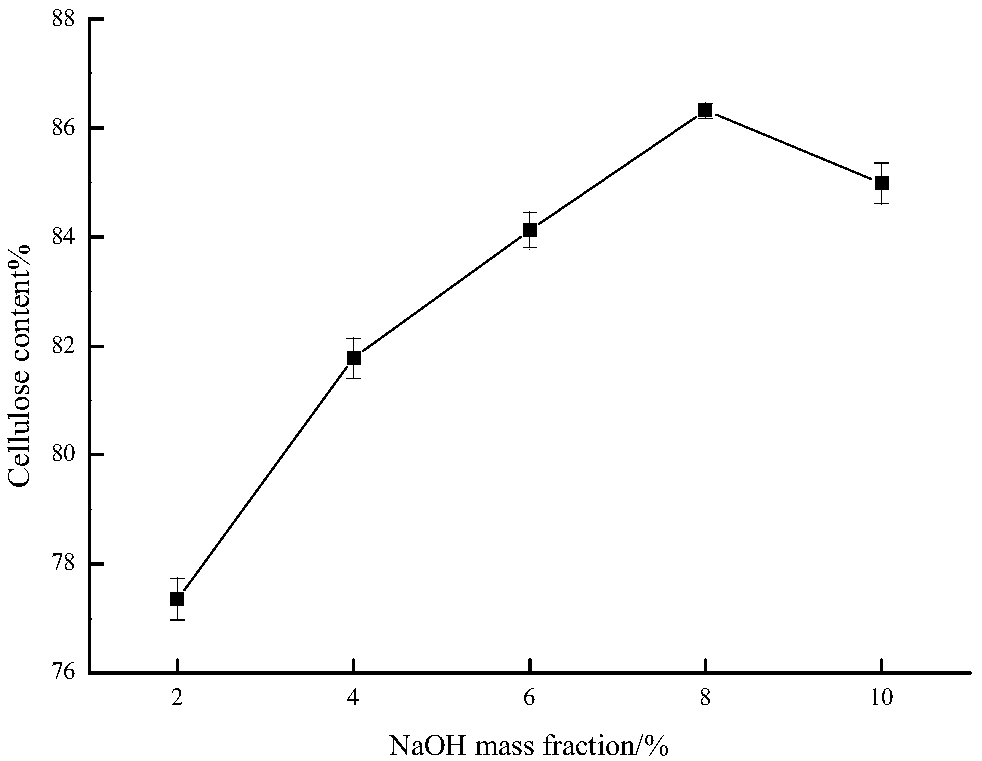

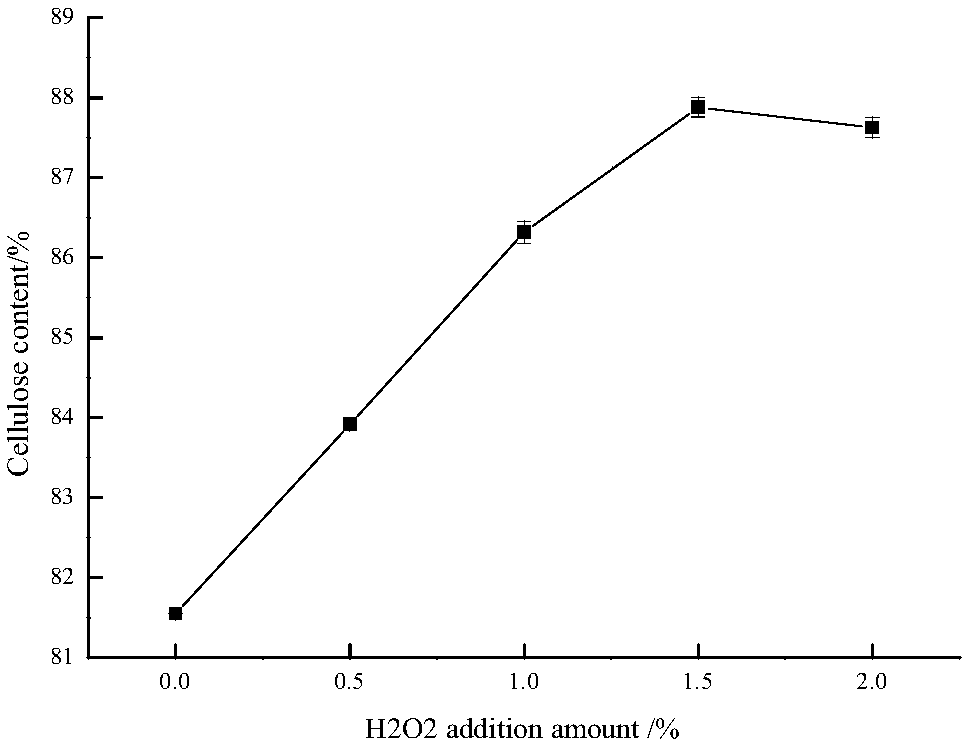

[0066] The sugarcane leaves of Yuetang No. 159 were used as raw materials in this experiment. It has been detected that the contents of three major components in the sugarcane leaves are: 40.26% cellulose, 23.06% hemicellulose and 17.16% lignin. The sugarcane leaves were pretreated by alkaline hydrogen peroxide method to remove lignin and hemicellulose in the sugarcane leaves. Taking the cellulose content of sugarcane leaves after treatment as the evaluation index, the optimal process conditions for preparing sugarcane leaf cellulose were found through single factor test and orthogonal test.

[0067] Pretreatment of sugarcane leaves

[0068] The sugarcane leaves taken from the field are washed with water several times to remove impurities such as soil on the surface, and then dried naturally. Carry out pulverization with pulverizer and cross 60 mesh sieves for subsequent use. Accurately weigh a certai...

Embodiment 2

[0207] A preparation method for hydrophobically modified nano-cellulose of sugarcane leaves, comprising the steps of:

[0208] (1) according to the ratio by weight of sugarcane leaf nanocellulose and stearic acid is 0.5:1 to take raw materials, then described sugarcane leaf nanocellulose and stearic acid are dropped into acetone and mixed to obtain dispersion system,

[0209] (2) Put the dispersion system under the condition of 20°C for modification treatment for 60min,

[0210] (3) Washing continuously with an organic solvent capable of dissolving stearic acid until all stearic acid not participating in the reaction is removed, and then drying to obtain the modified nanocellulose.

[0211] Preferably, in step (1), in the dispersion system, the concentration of stearic acid is 6mmoL.L -1 .

[0212] Preferably, in step (1), in the dispersion system, the concentration of sugarcane leaf nanocellulose is 1 mg.L -1 .

[0213] Preferably, the preparation method of the sugarcane ...

Embodiment 3

[0221] A preparation method for hydrophobically modified nano-cellulose of sugarcane leaves, comprising the steps of:

[0222] (1) according to the ratio by weight of sugarcane leaf nanocellulose and stearic acid is 2:1 to take raw materials, then described sugarcane leaf nanocellulose and stearic acid are dropped into benzene and mix to obtain dispersion system,

[0223] (2) Place the dispersion at 70°C for 100 minutes of modification treatment,

[0224] (3) Washing continuously with an organic solvent capable of dissolving stearic acid until all stearic acid not participating in the reaction is removed, and then drying to obtain the modified nanocellulose.

[0225] Preferably, in step (1), in the dispersion system, the concentration of stearic acid is 1mmoL.L -1 .

[0226] Preferably, in step (1), in the dispersion system, the concentration of sugarcane leaf nanocellulose is 2 mg.L -1 .

[0227] Preferably, the preparation method of the sugarcane leaf nanocellulose compr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com