Magnesium oxychloride-based immature soil curing agent and preparation method and application thereof

A technology of magnesium oxychloride-based raw soil and curing agent, which is used in manufacturing tools, ceramic molding machines, etc., can solve the problems of poor water resistance, low strength, and high energy consumption, and achieve high curing strength, good water resistance, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

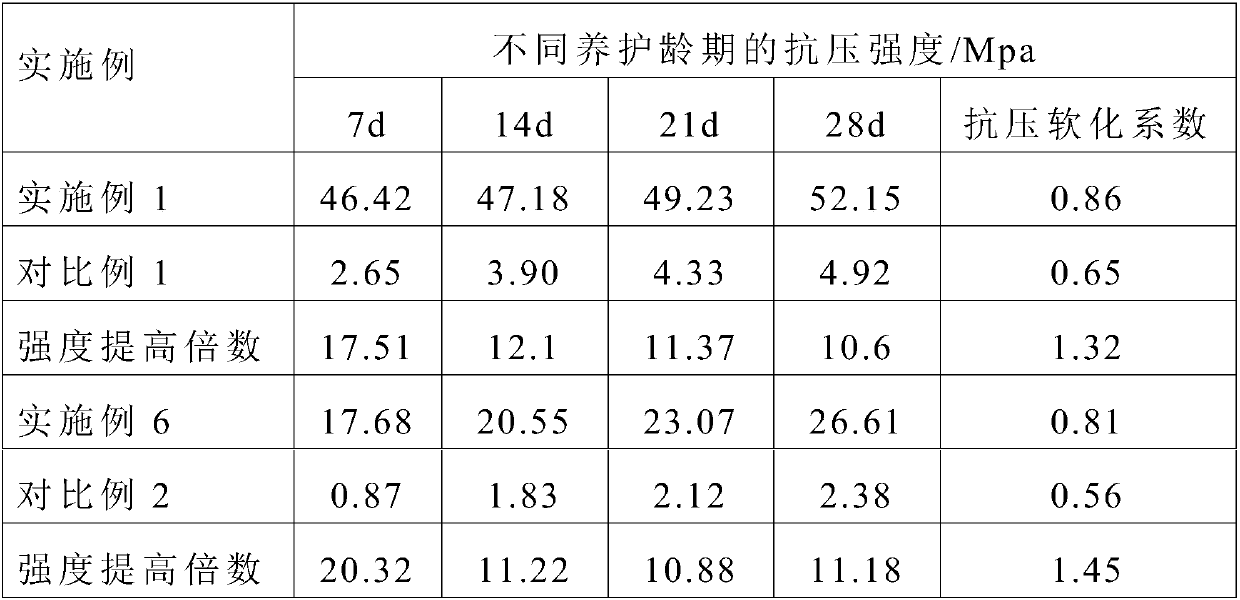

Examples

Embodiment 1

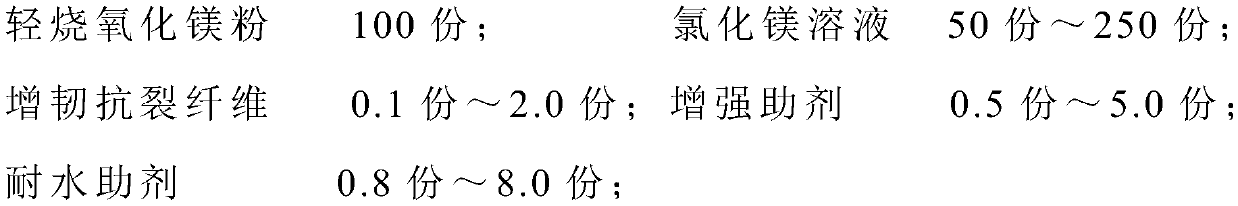

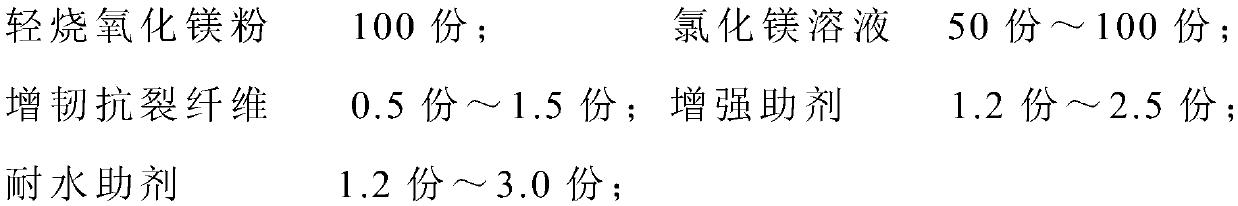

[0027] A magnesium oxychloride-based soil curing agent, by weight, the magnesium oxychloride-based soil curing agent comprises: 100 parts of lightly burned magnesium oxide powder, density 1.15g / cm 3 67 parts of magnesium chloride solution, 0.5 parts of polyvinyl alcohol fiber, 1.5 parts of phosphoric acid and sodium dihydrogen phosphate (1:1 by weight), 1.5 parts of ferrous sulfate.

[0028] Preparation process: prepare materials according to the above ratio; put the magnesium chloride solution into the mixer, add polyvinyl alcohol fiber (toughened and crack-resistant fiber), phosphoric acid and sodium dihydrogen phosphate (strengthening aid), stir for 2 minutes, and then add light-burned magnesium oxide powder, stir for 3 minutes, and finally add ferrous sulfate (water-resistant additive), and stir for 2 minutes to obtain magnesium oxychloride-based soil curing agent.

[0029] Raw soil curing: by weight, take 20 parts of raw soil and 170 parts of the above-mentioned magnesium...

Embodiment 2

[0032] A magnesium oxychloride-based soil curing agent, by weight, the magnesium oxychloride-based soil curing agent comprises: 100 parts of lightly burned magnesium oxide powder, density 1.15g / cm 3 79.5 parts of magnesium chloride solution, 0.6 parts of polyvinyl alcohol fiber, 1.3 parts of citric acid and sodium dihydrogen phosphate (1:1 by weight), 1.3 parts of ferrous sulfate.

[0033] Preparation process: prepare materials according to the above ratio; put the magnesium chloride solution into the mixer, add polyvinyl alcohol fiber (toughening and anti-cracking fiber), citric acid and sodium dihydrogen phosphate (strengthening aid), stir for 3 minutes, and then add light burning oxidation Magnesium powder, stirred for 3 minutes, and finally added ferrous sulfate (water-resistant additive), stirred for 2 minutes to obtain magnesium oxychloride-based soil curing agent.

[0034] Raw soil curing: by weight, take 60 parts of raw soil and 183 parts of the above-mentioned magnesi...

Embodiment 3

[0037] A magnesium oxychloride-based soil curing agent, by weight, the magnesium oxychloride-based soil curing agent comprises: 100 parts of lightly burned magnesium oxide powder, density 1.15g / cm 3 94 parts of magnesium chloride solution, 0.7 parts of polyvinyl alcohol fiber, 2.0 parts of citric acid and sodium dihydrogen phosphate (1:1 by weight), 2.0 parts of ferrous sulfate.

[0038] Preparation process: prepare materials according to the above ratio; put the magnesium chlorate solution into the mixer, add polyvinyl alcohol fiber (toughened and anti-crack fiber), citric acid and sodium dihydrogen phosphate (strengthening aid), stir for 3 minutes, and then add light Burn magnesium oxide powder, stir for 3 minutes, and finally add ferrous sulfate (water resistance additive), and stir for 2 minutes to obtain magnesium oxychloride-based soil curing agent.

[0039] Raw soil curing: by weight, take 90 parts of raw soil and 198 parts of the above-mentioned magnesium oxychloride-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com