An automated production line based on intelligent industrial robots

An automatic production line and industrial robot technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of non-automatic adjustment, low assembly efficiency, and easy falling off of workpieces, so as to avoid shaking or flipping and unnecessary losses , practicability and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Such as Figure 1-20 As shown, this embodiment provides an automated production line based on intelligent industrial robots, which includes a production line body 00, a handling mechanism 01 is provided at the production line body 00, and an assembly clamping mechanism 02 is provided at the handling mechanism 01;

[0055] In the present invention, the production line body 00 can be preferably formed through the transport mechanism 01 and the assembly clamping mechanism 02 , thereby facilitating the installation and use of the production line body 00 .

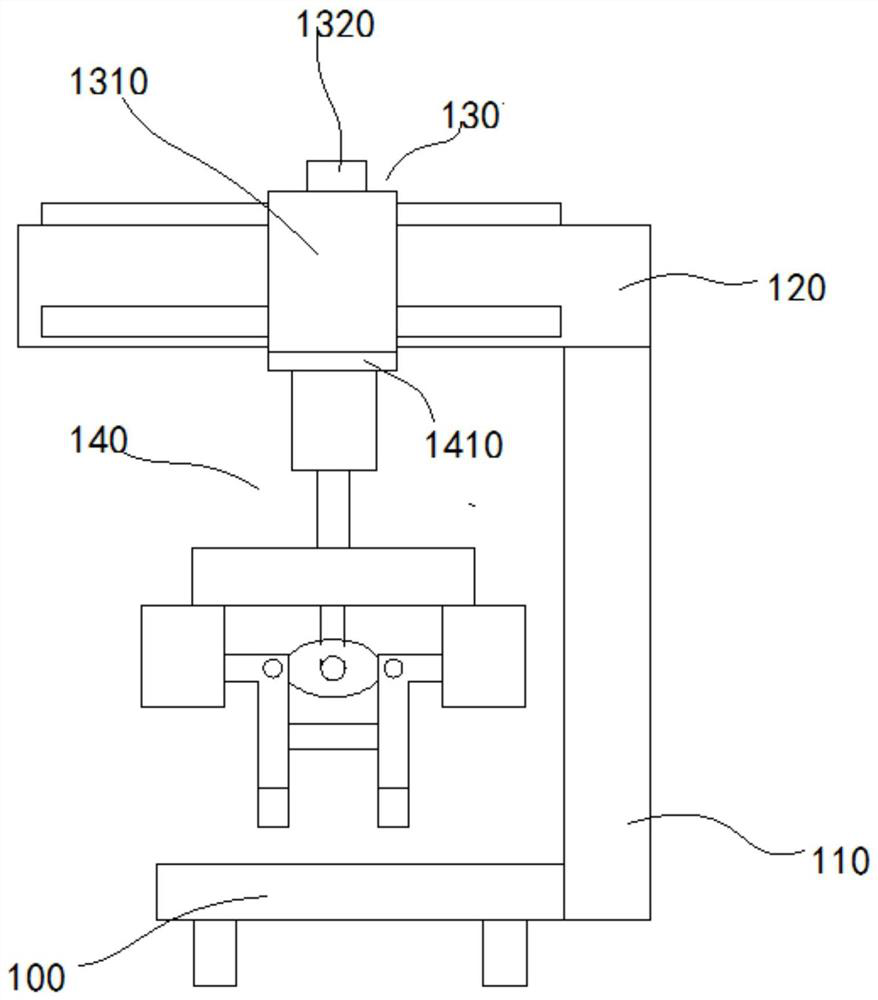

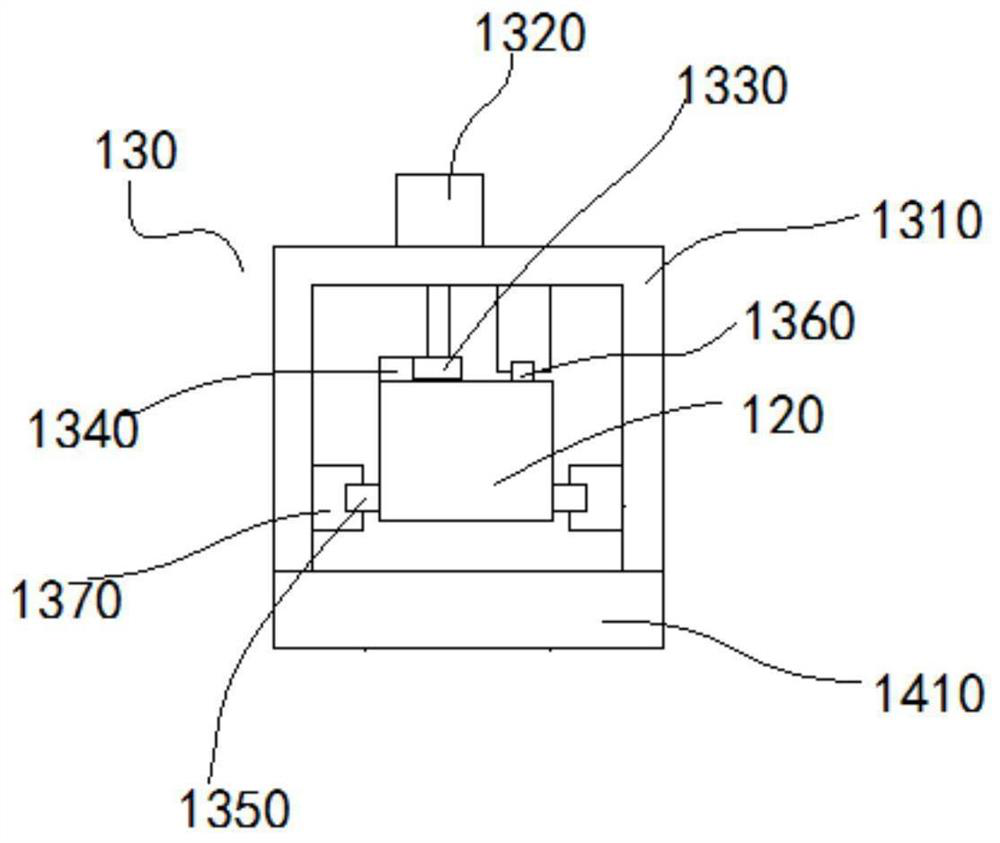

[0056] The transport mechanism 01 includes a conveying platform 100, the right side of the conveying platform 100 is provided with a support column 110, the top of the support column 110 is provided with a crossbeam 120, and the crossbeam 120 is provided with a first mobile device 130 that can slide left and right, the first mobile device A handling device 140 is provided below 130;

[0057] The first moving device 130 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com