Longitudinal direction moving carrier of switchable moving system and application method

A technology of vertical movement and trolley, which is applied in the field of engineering technology and science, can solve the problems of a single structure of the running system and the inability of large machinery to enter the construction site, and achieve the effect of convenient transition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: Structural composition of a longitudinally mobile trolley with switchable traveling system

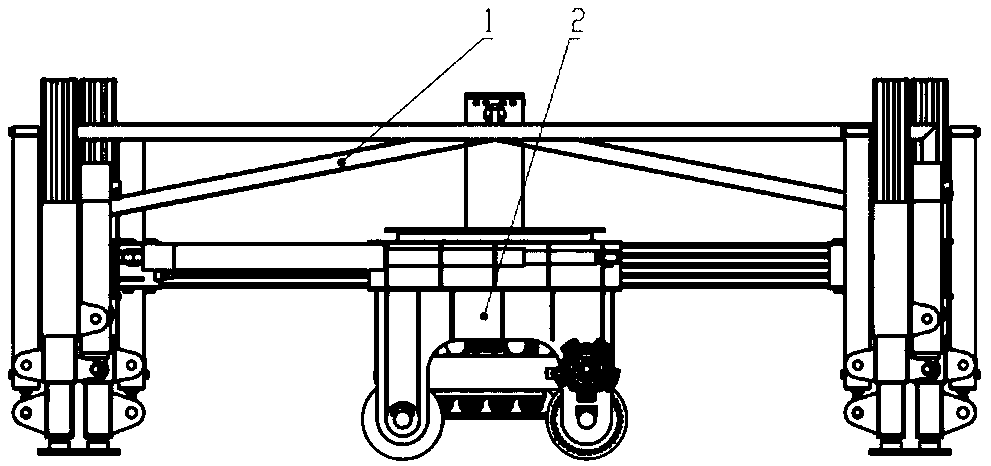

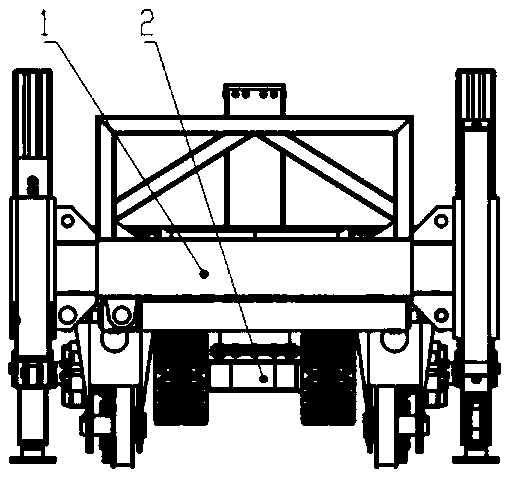

[0038] In order to achieve the above purpose, the present invention mainly adopts two sets of independent and different running systems that can be switched freely without affecting each other and has its own outrigger jacking system, which can be jacked up to make the trolley cross the traffic obstacle. This invention is mainly made up of two major parts, is respectively: outrigger supporting mechanism 1, trolley mechanism 2. As shown in Figure 1.

[0039] Outrigger support mechanism 1 consists of outrigger guide column 1-1, outrigger guide sleeve 1-2, outrigger jacking hydraulic cylinder 1-3, outrigger horizontal push-pull hydraulic cylinder 1-4, outrigger horizontal guide sleeve 1-5 , horizontal guide columns 1-6 for outriggers, longitudinal guide beams 1-7, and reinforced trusses 1-8. The outrigger guide column 1-1 is a hollow tubular structure, and the lower...

Embodiment 2

[0041] Embodiment 2 A method of using a longitudinally moving trolley with a switchable traveling system

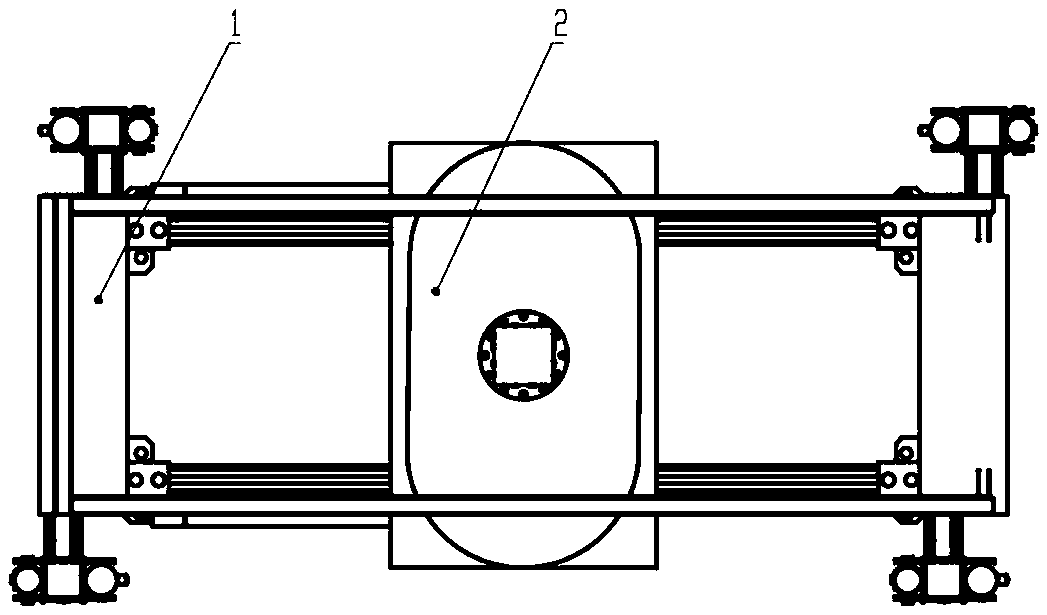

[0042] 1. When the trolley is walking on the track-paved section, when the trolley uses the traveling wheel set 2-2, 2-3 to walk on the track, the operation control system adjusts the hydraulic cylinder 2-9, so that the crawler mechanism shrinks to the left and right. The space between the outrigger plates of each wheel set does not affect the use of the wheel set.

[0043] 2. When the trolley travels to the section where the track is not laid, the trolley needs to switch the running system, from the original wheel set running system to the crawler running system, and the operation control system adjusts the hydraulic cylinder 2-9, so that the crawler mechanism can be lifted The telescopic guide sleeve guide column 2-6 lowers the crawler belt running system to be lower than the tread of the wheel set, so that the crawler belt can directly walk on the ground or the structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com