Clothing printing device

A printing and clothing technology, applied in printing, printing presses, transfer printing, etc., can solve the problems of reduced fit, cumbersomeness, and reduced clothing fixing ability, and achieve the effect of convenient repair and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

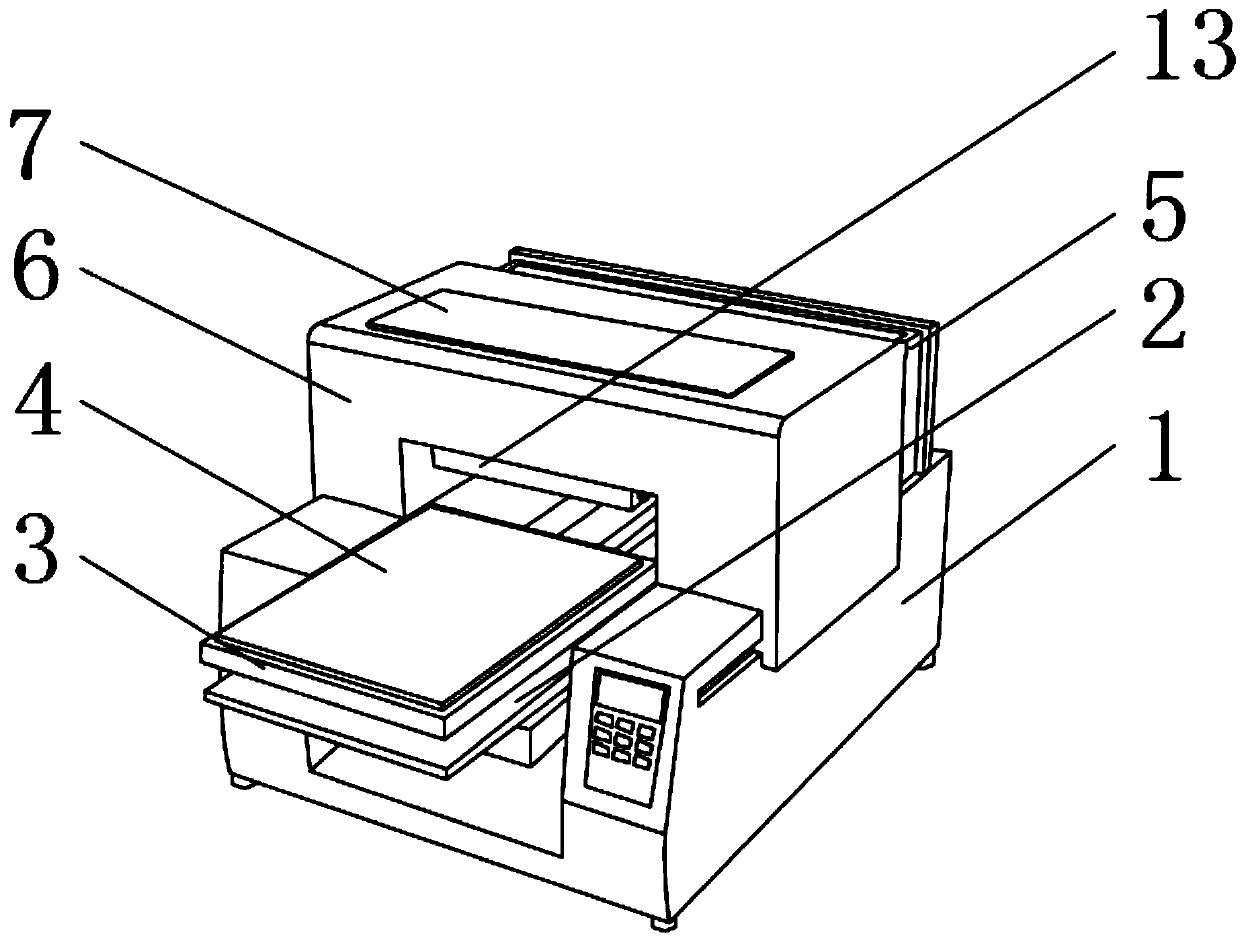

Embodiment 1

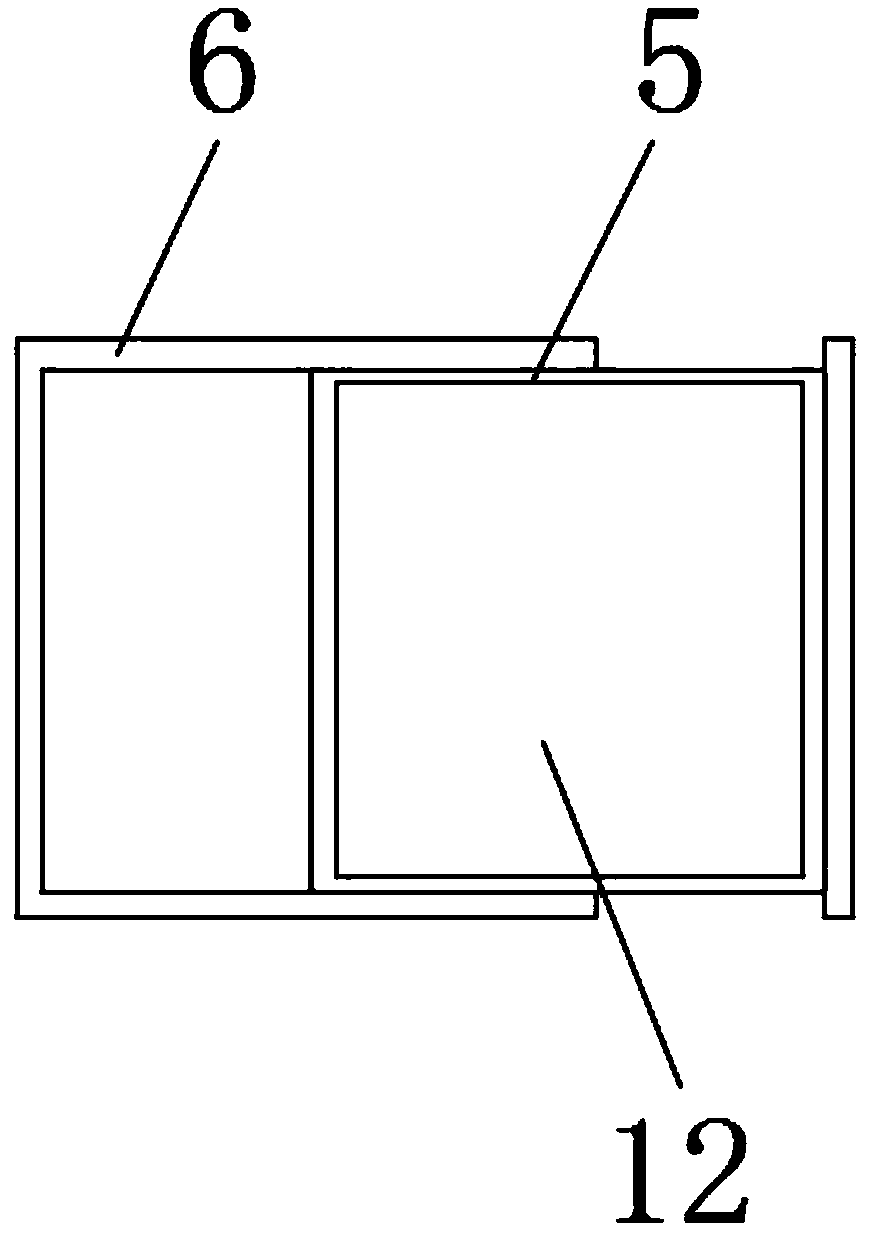

[0032] refer to figure 2 As shown, the position of the top outer surface of the base 1 close to the fixed frame 5 is movably installed with a sliding shell 6 through the slide rail, and the top outer surface of the sliding shell 6 is movably mounted with a feeding plate 7 through a hinge, and the inside of the fixed frame 5 is opened. There are circuit slots 12 .

[0033] refer to figure 2 The outer surface of the rear end of the fixed frame 5 is inlaid with a lock cylinder near the top position, and the fixed frame 5 and the sliding shell 6 are conveniently fixed by installing the lock core, and the outer surface of the rear end of the sliding shell 6 is welded near the position of the fixed frame 5 The handle is provided on the surface of the sliding housing 6 to facilitate maintenance personnel to slide the sliding housing 6 forward.

[0034] By installing slide rails on both sides of the sliding housing 6, the sliding housing 6 can be easily slid forward and backward. ...

Embodiment 2

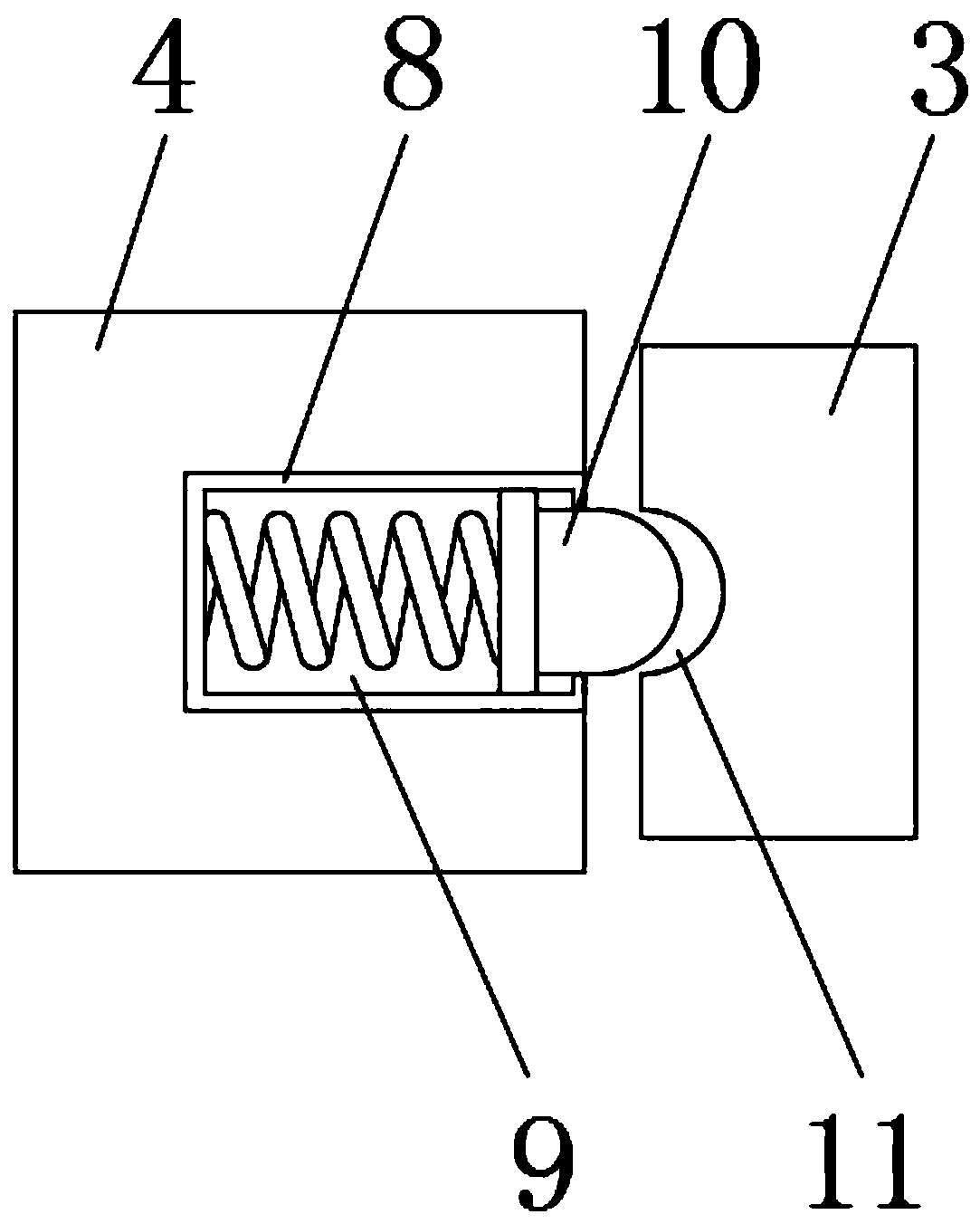

[0036] refer to image 3 As shown, the inside of the printing table 4 is fixedly installed with a shrinking frame 8 close to the position of the clamping frame 3, and the inside of the shrinking frame 8 is provided with a shrinking groove 9, and the inner surface of the shrinking groove 9 is equipped with an extrusion head 10 through a spring. A groove 11 is formed on the inner surface of the frame 3 near the extrusion head 10 .

[0037] By setting the extruding head 10 that can expand and contract on the outer surface of the printing table 4, when the clothing is fixed, the extruding head 10 will squeeze the clothing between the printing table 4 and the clamping frame 3 under the action of the rear end spring. Pressing, fixed by extrusion, can closely fit clothes of different thicknesses, and at the same time, a groove 11 is opened at the position close to the extrusion head 10 inside the clamping frame 3, when the extrusion head 10 stretches When the clothes are squeezed in...

Embodiment 3

[0039] refer to Figure 4-6 As shown, the outer surface of the bottom end of the sliding housing 6 is fixed with an ironing frame 13 by bolts near the front end, and the outer surface of the bottom end of the ironing frame 13 is provided with a placement groove 14, and the inner bottom surface of the placement groove 14 is close to the positions on both sides. Laser range finder 15 is fixedly installed, and the outer surface of the bottom end of ironing frame 13 is provided with a plurality of atomizing nozzles 17 near the front position, and the inside of ironing frame 13 is fixedly equipped with electric telescopic rod 18 near both sides. And between the two groups of electric telescopic rods 18, a shaft rod 20 is welded, and the outer surface of the shaft rod 20 is movably installed with a hot pressing roller 16 through a bearing, and a heating wire 19 is arranged between the hot pressing roller 16 and the shaft rod 20 .

[0040] refer to Figure 4 , one side outer surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com