Hydraulic engineering construction device and application method thereof

A technology for construction devices and water conservancy projects, applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of insufficient mixing of materials, slowing down construction efficiency, wasting labor and time, etc. The effect of cleaning, improving mixing efficiency and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples. The following examples are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

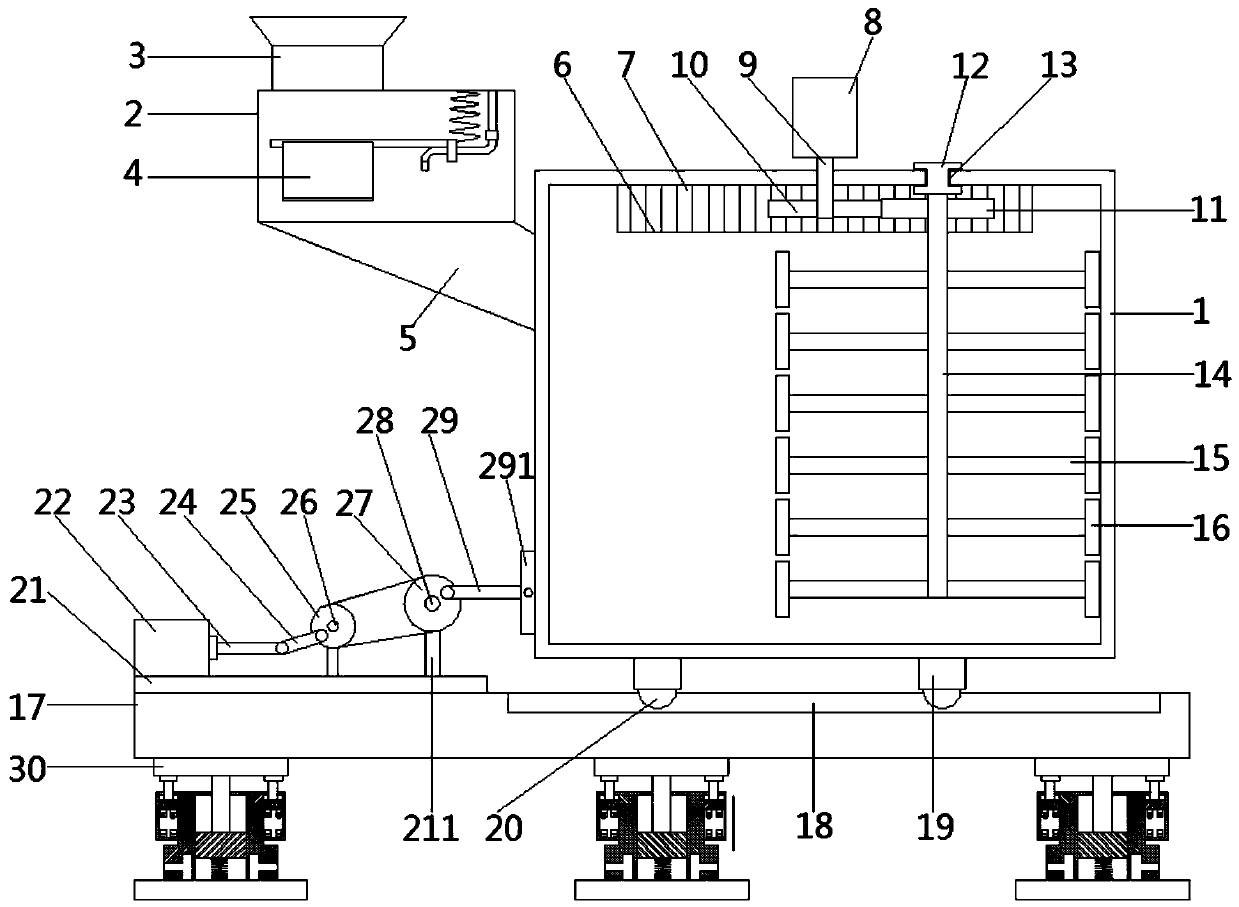

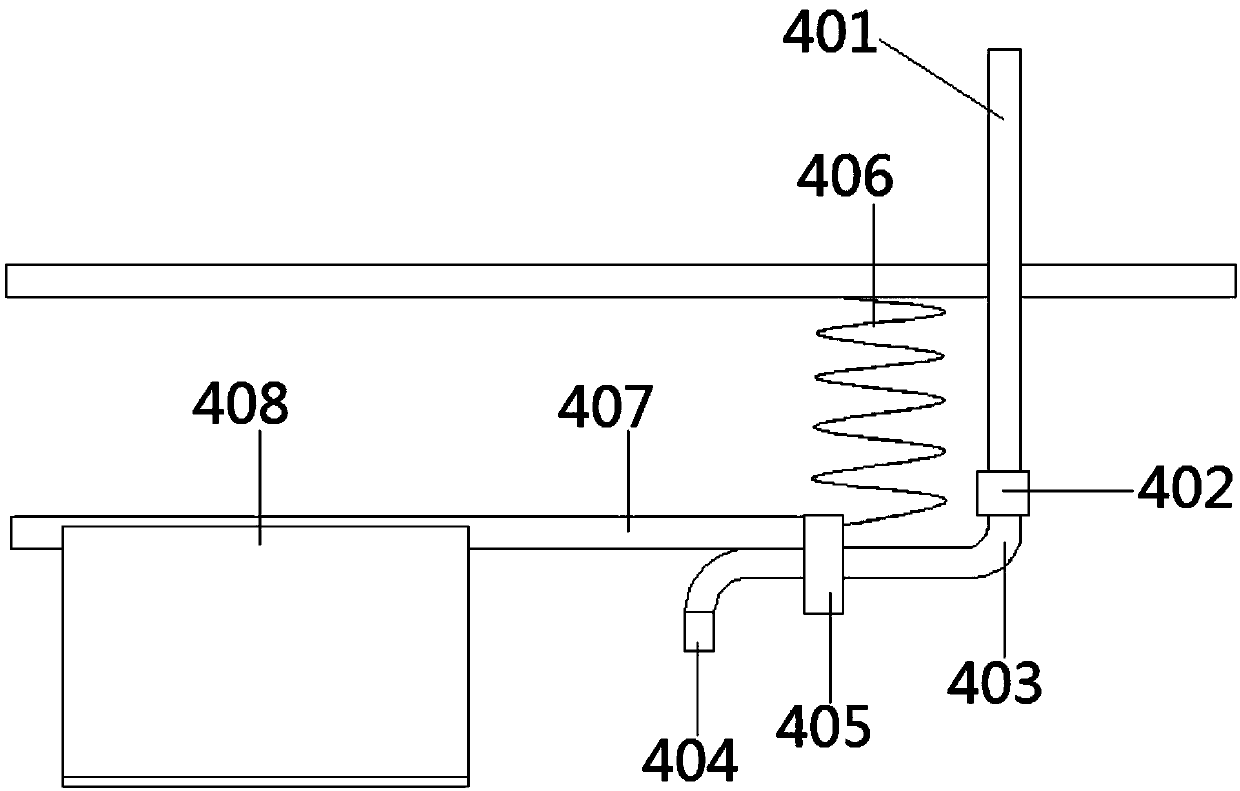

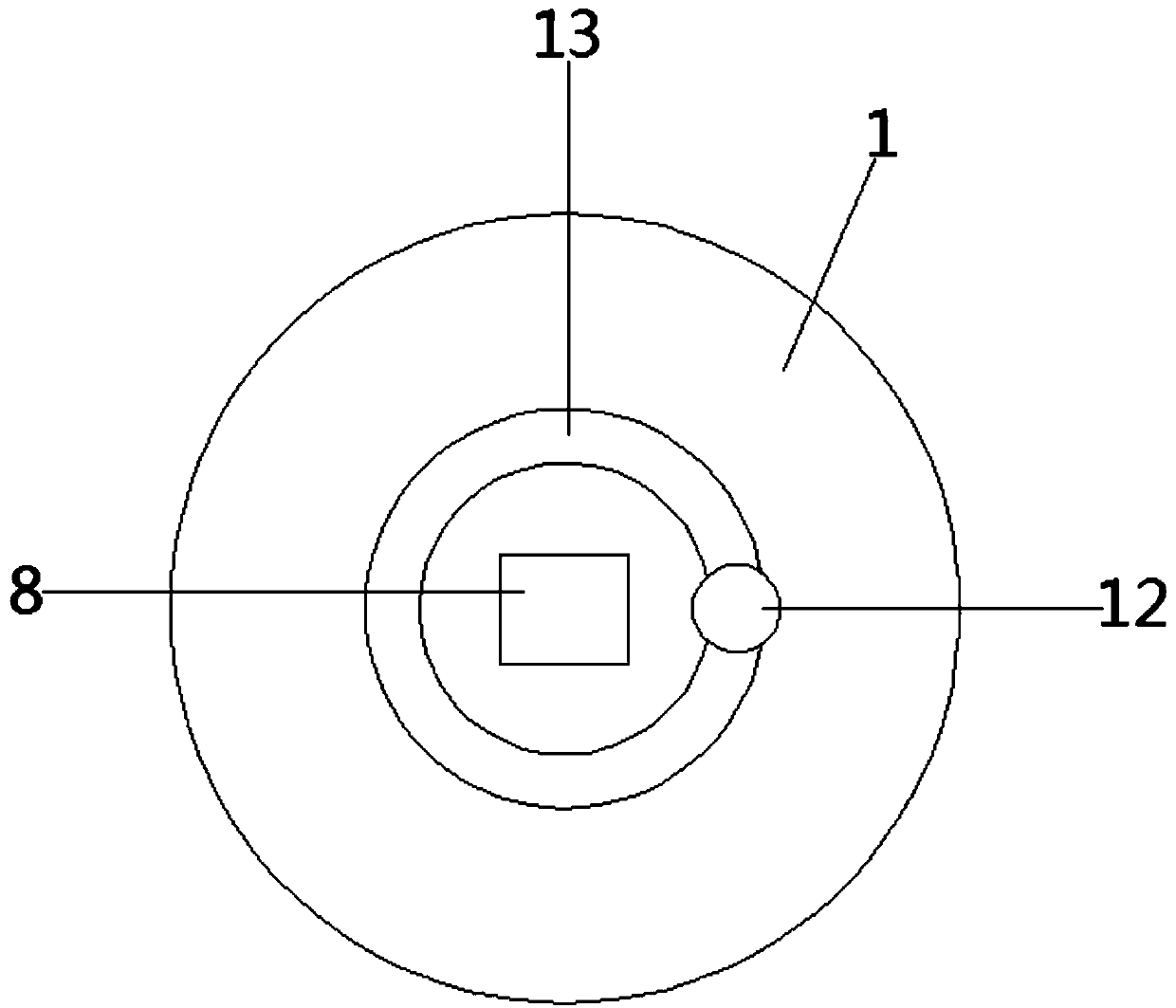

[0026] see figure 1 and figure 2 , in the embodiment of the present invention, a kind of water conservancy project construction device comprises machine body 1, and described 1 upper side left end is provided with feeding box 2, is provided with feeding hopper 3 on the upper side of feeding box 2, and feeding box 2 The bottom end of the body 1 is connected with the feeding port opened on the body 1 through the feeding pipe 5, and the body 1 is provided with a premixing device 4, which includes a fixed tube 401, a plastic elastic tube 403, a nozzle 404, a coil spring 406, Swing mechanism, one end of the fixed tube 401 is connected to the plastic elastic tube 403, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com