A zero position device and zero return method for a mechanical arm joint

A technology of mechanical arms and joints, which is applied in the field of robot rotary joint design, can solve problems such as interference and collision, and achieve the effects of saving change time, high repeat positioning accuracy, and reducing power-on initialization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

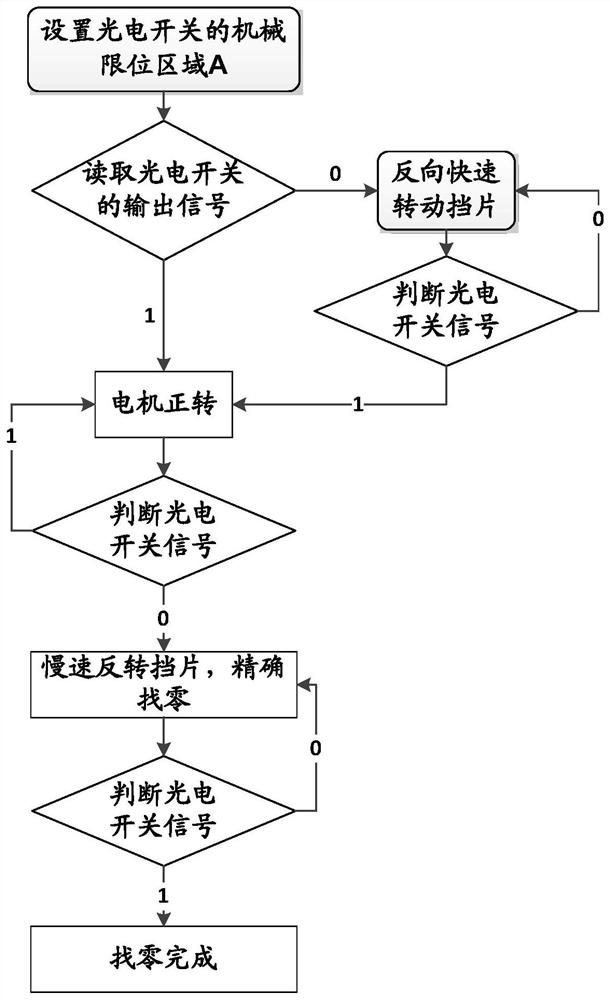

[0031] The invention provides a mechanical arm joint zero position device and a zero return method. The motion controller sends a motion command to the motor driver. Rotate, when the photoelectric switch 1 detects the zero position signal, it feeds back the position signal to the motion controller, and the motion controller obtains the absolute position information of the joint, and the robot joint zero return task is completed.

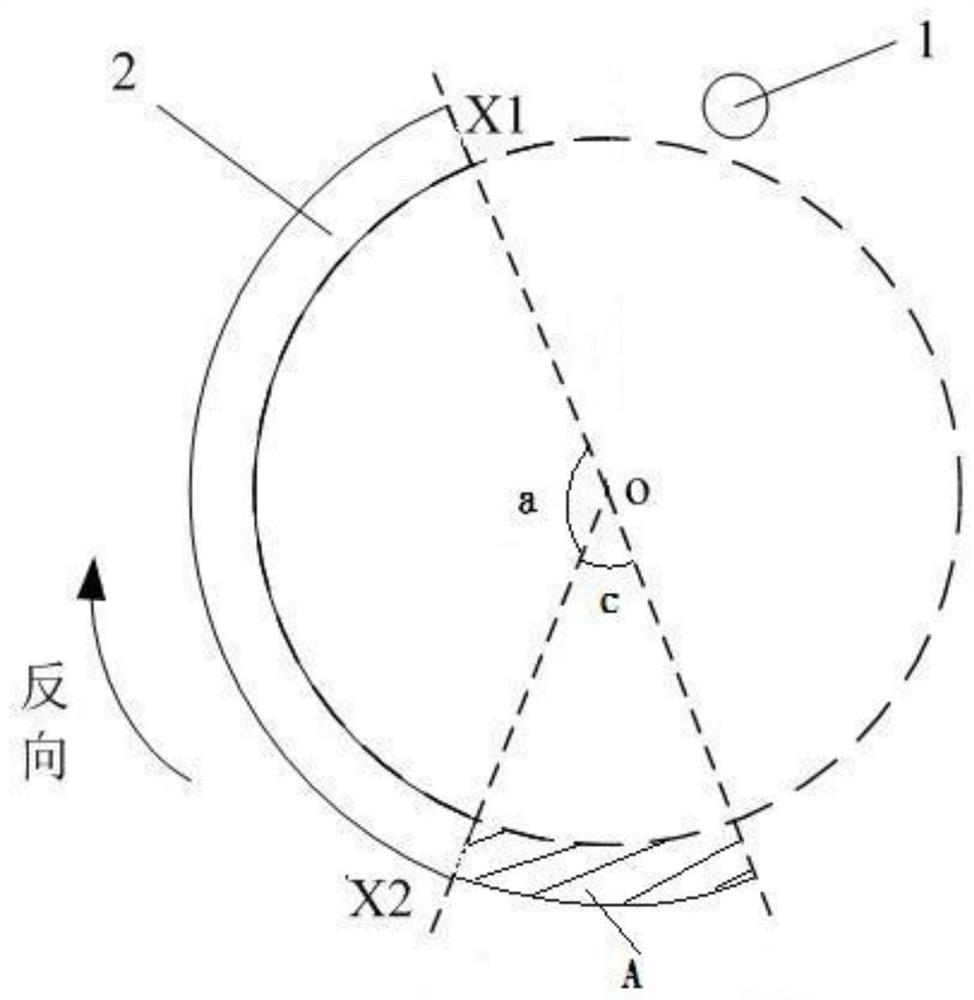

[0032] Such as figure 1 Shown is a schematic diagram of the zero position device of the mechanical arm joint. It can be seen from the figure that a kind of mechanical arm joint zero position device includes a photoelectric switch 1 and a stopper 2; wherein the stopper 2 is an arc-shaped sheet structure; the stopper 2 is o The point is the center of the circle for circular rotation; the photoelectric switch 1 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com