Dampness preventing mattress for students and production technology thereof

A production process and mattress technology, which is applied in the field of moisture-proof mattresses for students and its production process, can solve the problems of inconvenient cleaning and cleaning of mattresses, poor body fit of users, and affecting sleep quality of users, etc., to achieve Good air permeability, good comfort, and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

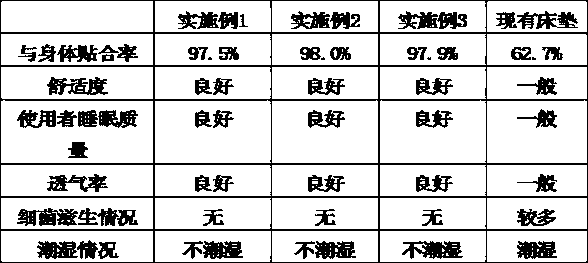

Embodiment 1

[0038] Washing 5 parts of Uralia sativa, 6 parts of chamomile and 4 parts of Agrimony, drying them after cleaning to make the water content 30%, and stir to mix the lye and latex evenly, at a speed of 100r / min, and mix for 5 minutes. Add 1 part of antioxidant, 1 1 part of zinc dimethyldithiocarbamate and benzothiazole, 2 parts of sulfur, 1 part of zinc oxide and 3 parts of silicate are added to the premixed material, and the mixing speed is adjusted to 350r / min, and mixed for 25min. Add the ground additives to the mixed material and mix evenly, then introduce the mixed material into the foaming machine for foaming treatment, squeeze the foamed material into the mold to fill the mold with material, put the mold into Put it into the steaming room for 15 minutes of setting treatment at 105°C, take out the mold after the material is shaped from the steaming room, open the mold, take out the molded mattress and clean it to cool down, and wash and cool down the mattress Carry out c...

Embodiment 2

[0040] Wash 6 parts of Uralia sativa, 6.5 parts of chamomile and 5 parts of Agrimony, dry them after cleaning to make the moisture content 30%, and stir to mix the lye and latex evenly, at a speed of 100r / min, and mix for 5 minutes. Add 1.5 parts of antioxidants, 1.25 1 part of zinc dimethyldithiocarbamate and benzothiazole, 2.5 parts of sulfur, 1.5 parts of zinc oxide and 3.5 parts of silicate were added to the premixed material, and the mixing speed was adjusted to 375r / min, and mixed for 25min. Add the ground additives to the mixed material and mix evenly, then introduce the mixed material into the foaming machine for foaming treatment, squeeze the foamed material into the mold to fill the mold with material, put the mold into Put it into the steaming room for 17 minutes of setting treatment at 110°C, take out the mold after the material is shaped from the steaming room, open the mold, take out the molded mattress and clean it to cool down, and wash and cool down the mattre...

Embodiment 3

[0042] Washing 7 parts of Uralia sativa, 7 parts of chamomile and 6 parts of Agrimony, drying them after cleaning to make the water content 30%, and stir to mix lye and latex evenly, rotating speed 100r / min, mix for 5min, add 2 parts of antioxidant, 1.5 1 part of zinc dimethyldithiocarbamate and benzothiazole, 3 parts of sulfur, 2 parts of zinc oxide and 4 parts of silicate are added to the premixed material, and the mixing speed is adjusted to 400r / min, and mixed for 25min. Add the ground additives to the mixed material and mix evenly, then introduce the mixed material into the foaming machine for foaming treatment, squeeze the foamed material into the mold to fill the mold with material, put the mold into Put it into the steaming room for 20 minutes of shaping treatment at 115°C, take out the mold after the material is shaped from the steaming room, and open the mold, take out the molded mattress and clean it to cool down, and wash and cool down the mattress Carry out centri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com