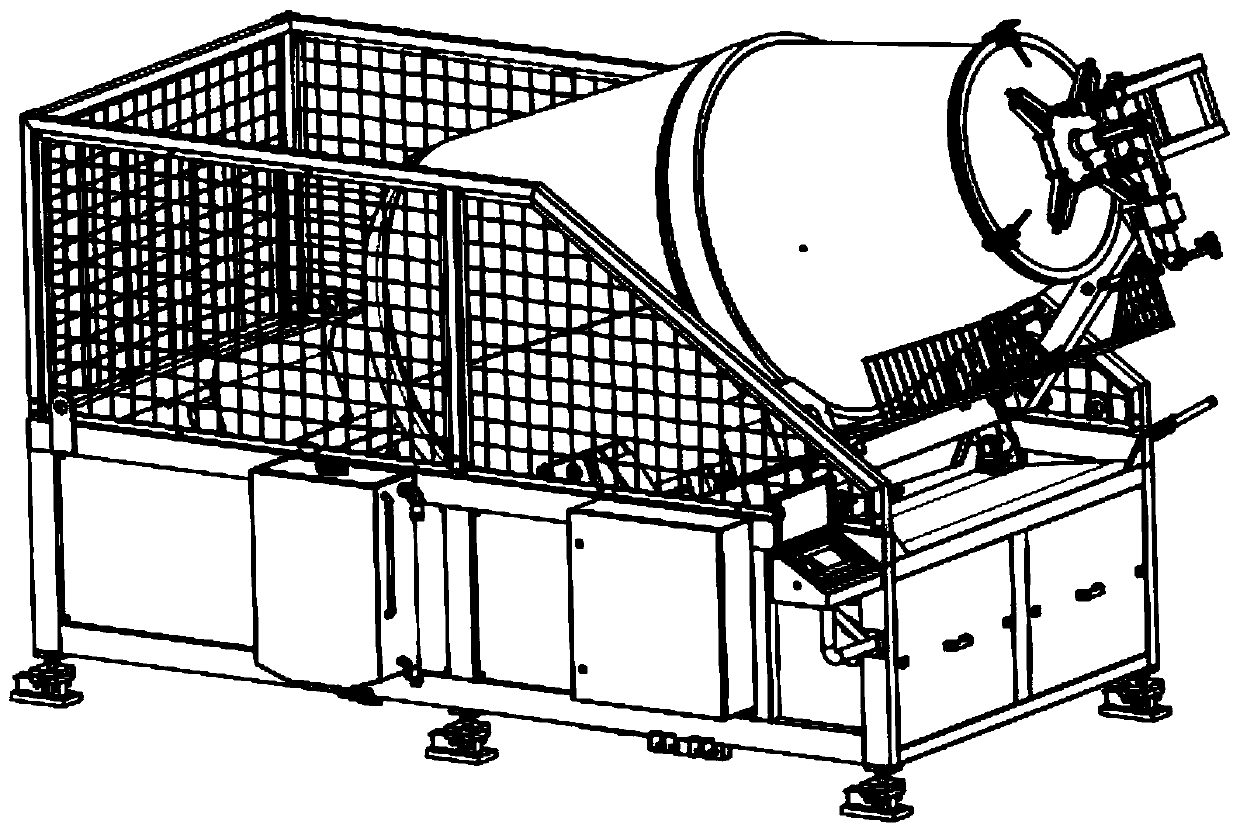

Tumbling machine

A tumbler and tumbler technology, used in slaughtering, meat tenderization, and softening by massaging the meat, etc., can solve the problems of damage to various components, high component damage rate and maintenance rate, increase production costs, etc., to avoid connection. The effect of mechanism damage, reducing floor space and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solution of the present invention is described in detail below. The embodiment of the present invention is only for illustrating a specific structure, and the scale of the structure is not limited by the embodiment.

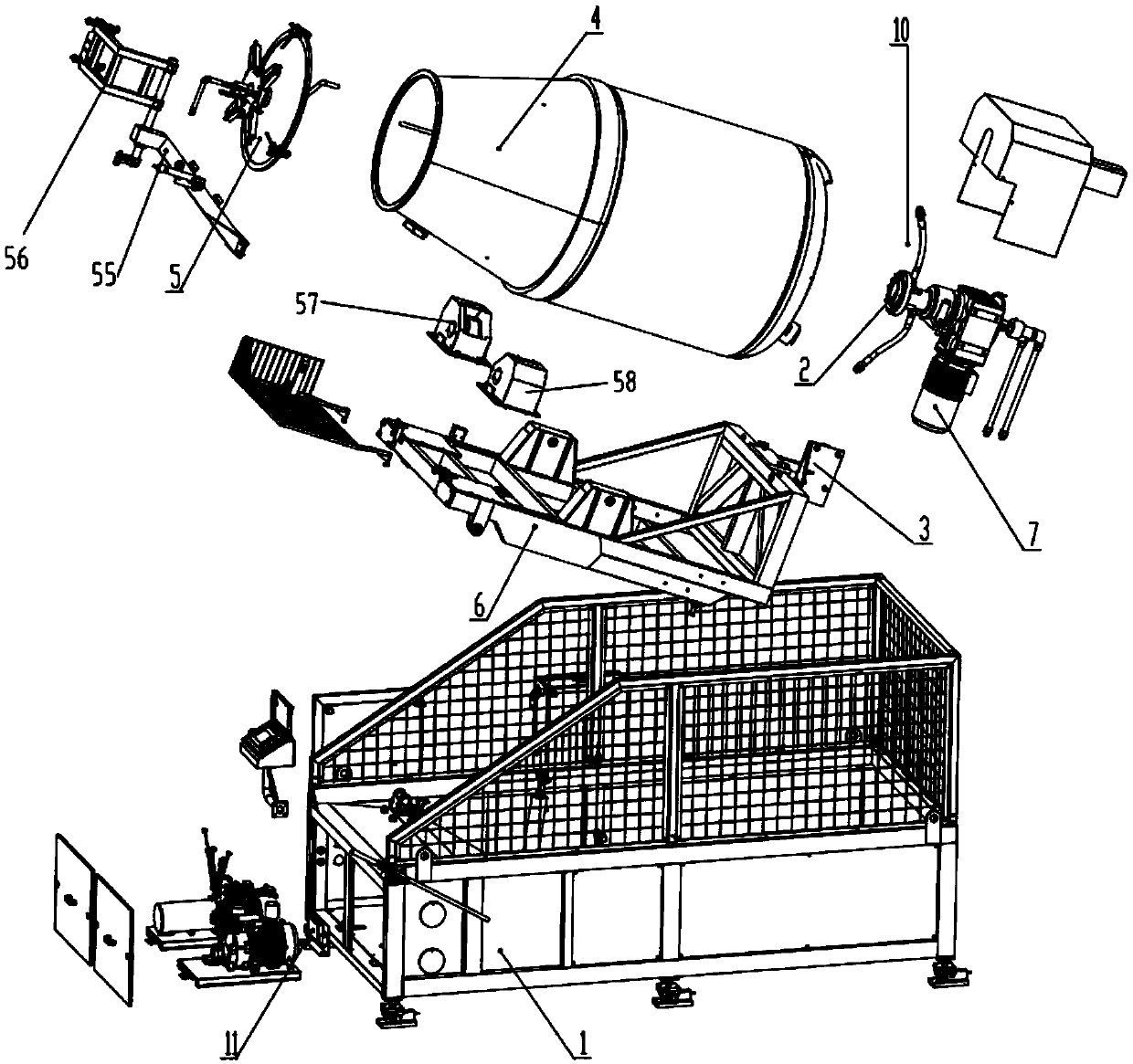

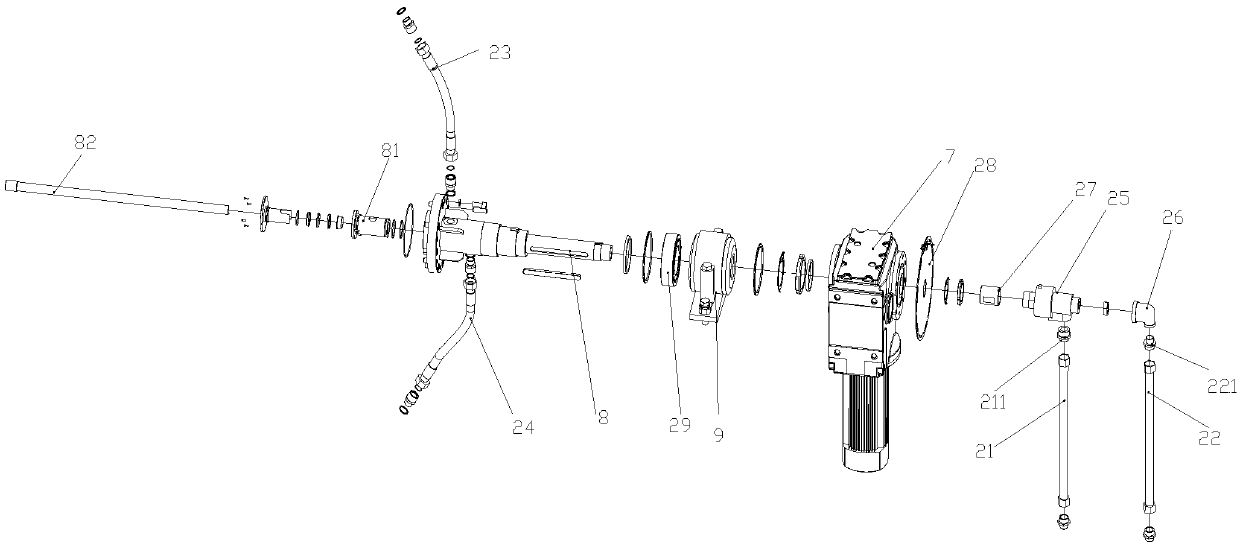

[0037] see Figure 1 to Figure 10 As shown, the tumbling machine includes a base 1, a transmission system 10, a tumbling barrel body 4, and a barrel cover 5; the front end of the tumbling barrel body 4 is supported by the left supporting wheel 57 and the right supporting wheel 58 on the swing frame 6, and the barrel The afterbody of the body is fixed on the afterbody of the swing frame 6 through the bearing seat, and an oil cylinder 59 is installed between the base 1 and the swing frame 6, and the horizontal inclination angle of the tumble barrel body is controlled by the expansion and contraction of the oil cylinder.

[0038] The tumbling barrel body 4 is obliquely fixed on the swing frame 6, and the swing frame 6 is installed on the base 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com