Feeding hopper fire extinguishing device suitable for garbage incinerator

A waste incinerator and fire extinguishing device technology, applied in the field of incineration, can solve problems such as unsmooth feeding, increased operating costs of power plants, hidden dangers, etc., to achieve the effects of solving fires, reducing the probability of shutdown, and avoiding operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

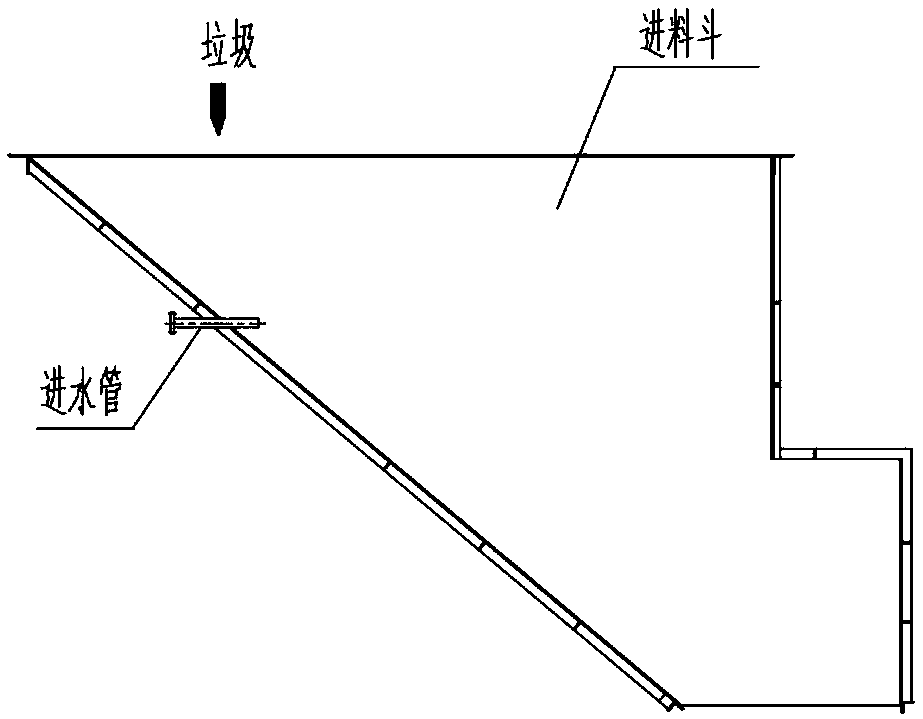

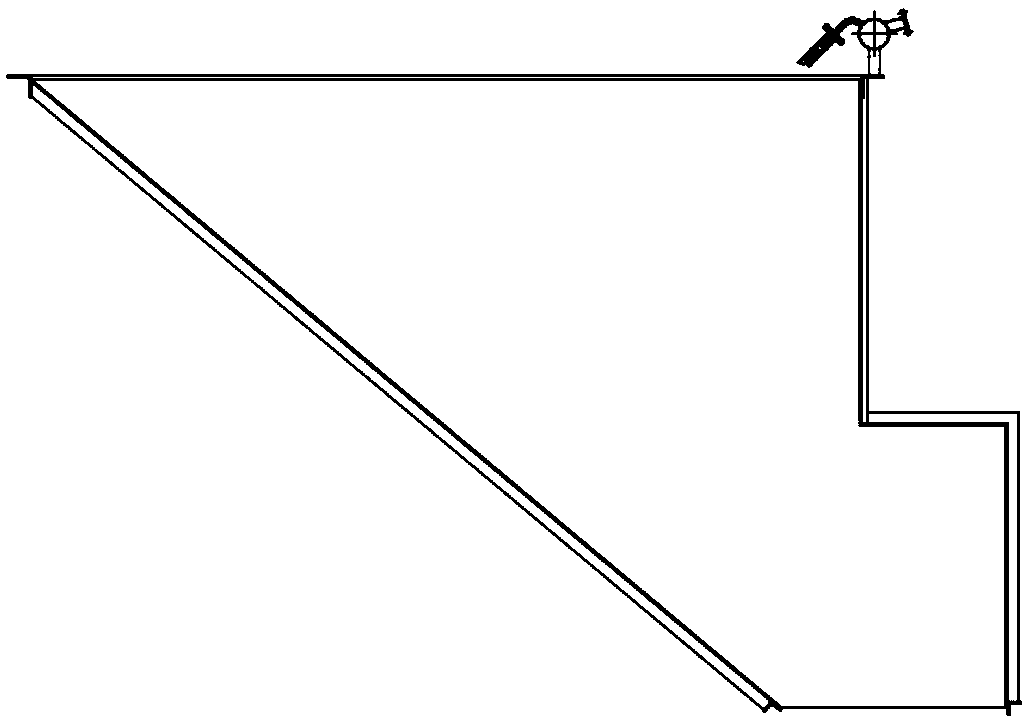

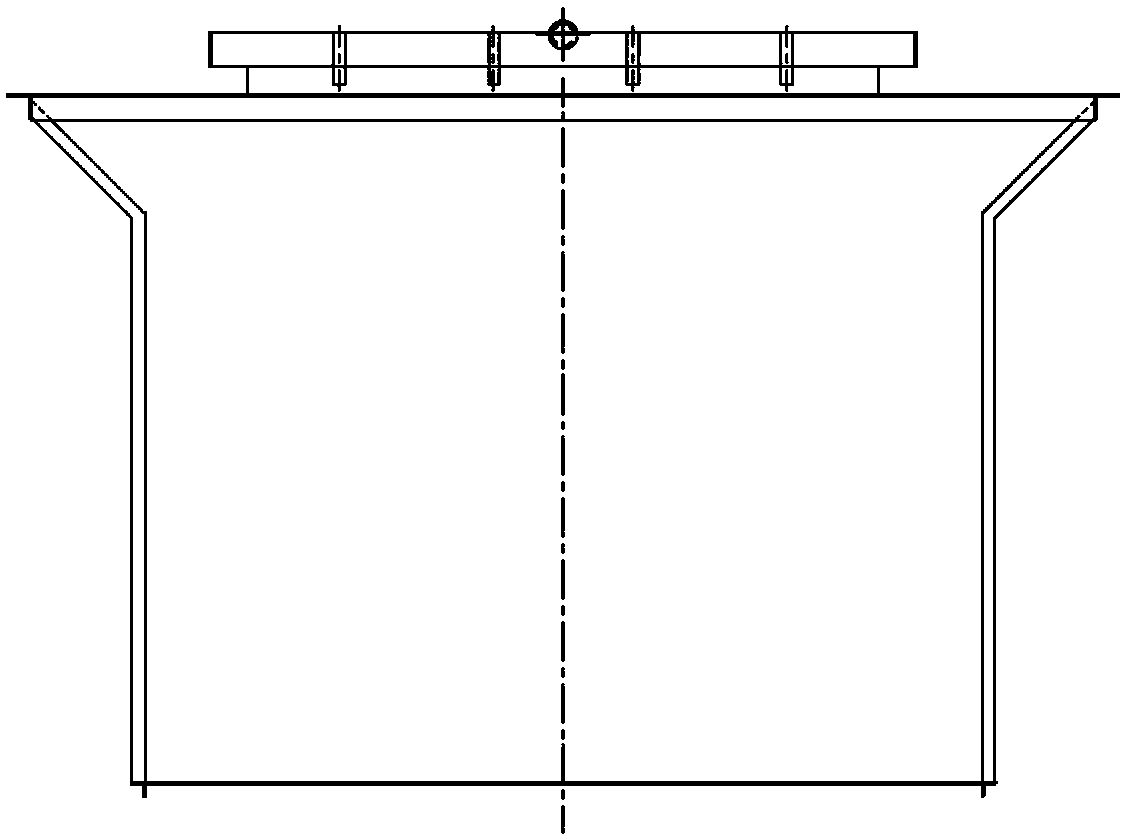

[0019] The fire extinguishing device mainly includes a support frame 101, a main pipe 201, an outlet pipe 301, a connecting first flange 302, a rubber gasket 303, connecting bolts and nuts 304, a nozzle 305, a water inlet pipe 401, and a connecting second flange 402.

[0020] The support frame 101 is welded on the feed hopper body to play a role of fixed support.

[0021] Assemble the water outlet pipe 301 , connecting the first flange 302 , the rubber gasket 303 , connecting bolts and nuts 304 , and the nozzle 305 , and then insert and weld them into the wall 201 of the main pipe.

[0022] The water inlet pipe 401 is inserted and welded into the main pipe wall 201, and the second flange 402 is assembled and connected at the same time.

[0023] The assembled and welded fire extinguishing equipment is placed on the support frame 101 and fixed in place by welding.

[0024] After the fire extinguishing device of the feeding hopper is installed, the spontaneous combustion phenome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com