Well-shaped beam formwork support and its design and construction method

A construction method, the technology of the well-shaped beam, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problem of not being able to meet the requirements of the same height of the formwork at the bottom of the vertical and horizontal well-shaped beams, and damage the bottom of the beam Formwork main flute, affecting the construction period and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

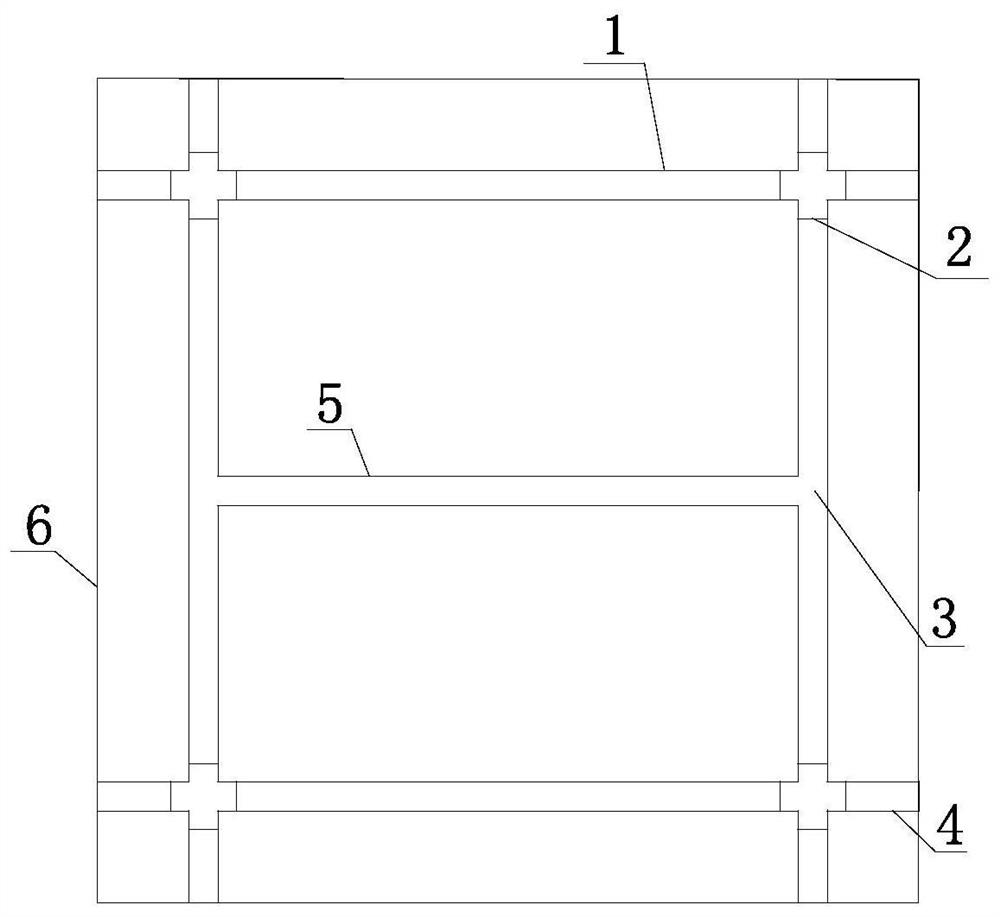

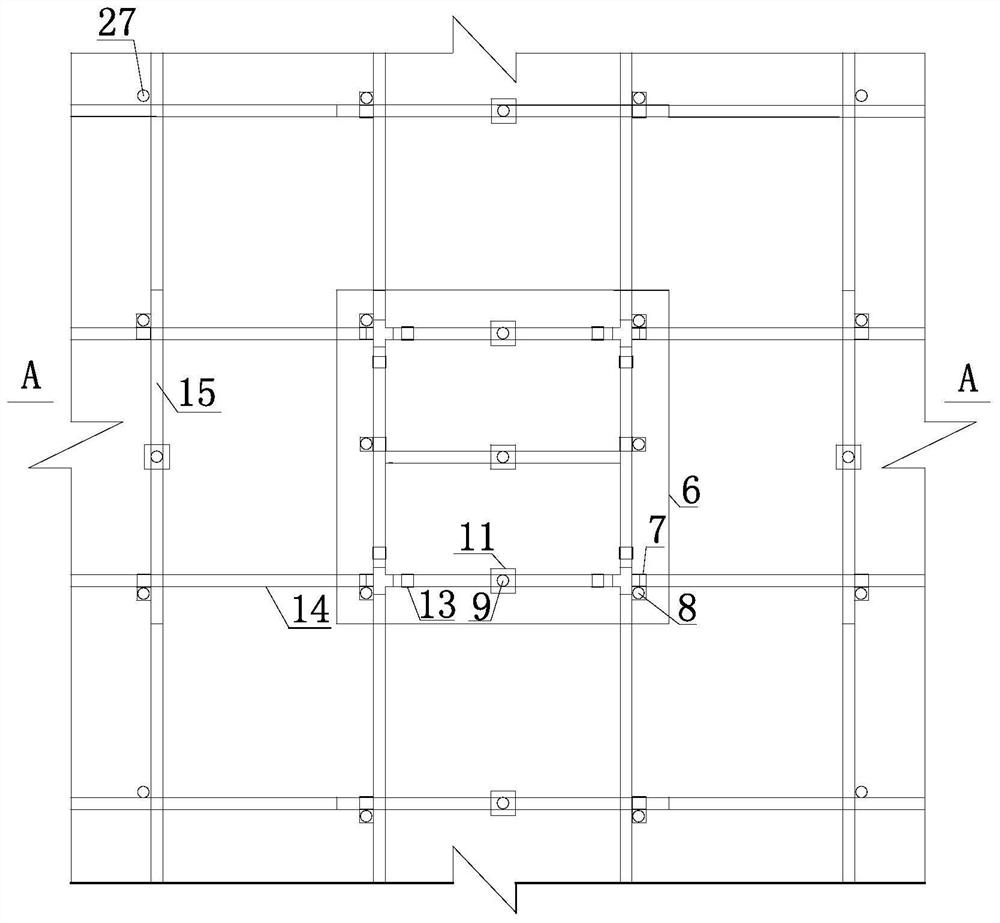

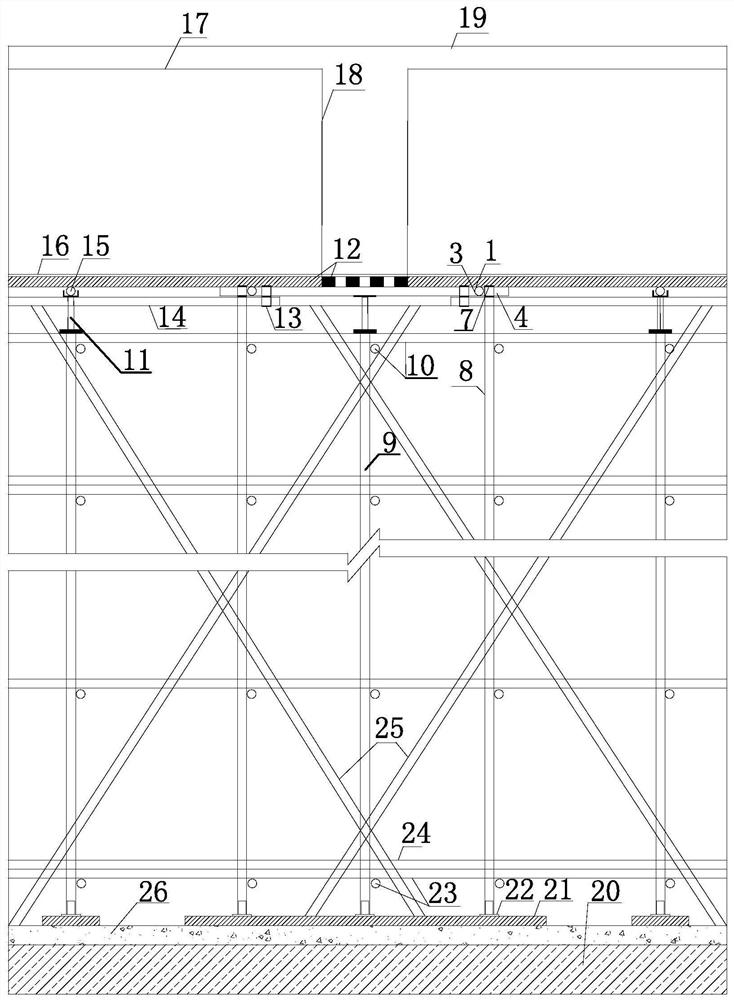

[0168] Such as Figure 1-3 As shown, the well-known beam template holder of the present embodiment, includes a beam bottom template tray 6, a beam bottom rod 9, and a beam side vertical rod 8, the beam bottom template tray 6 includes two crossbar 1, two vertical The rod 3, a mid rod 5, four tetranes 2 and 8 epitaxial rod 4, the two crossbar 1 and the two joysticks 3 are welded to rectangular shape by four four-pass 2, four four-way 2 outer interface welding Extended rod 4, two longitudinal rod 3 length midpoint position welding mid-rod 5; the outer extension rod 4 separates the longitudinal horizontal beams 18 and the longitudinal horizontal rod 14 under the beam of the lateral well-beam 17, using a rotary buckle The member 13 is connected firmly, and the beam side vertical rod 8 of the transverse well grave beam 17 is securely connected to the cross fastener 7; the longitudinal horizontal rod 14 of the beam side rod 8 and the beam is connected to the cross fastener 7; beam bottom ...

Embodiment 2

[0170] Based on the embodiment, the present embodiment provides a well-known beam template bracket design and construction method, including the following steps:

[0171] I. Well word beam template bracket construction drawing design:

[0172] 1) On-site acquisition and confirm the material varieties, specifications and physical mechanical performance indicators used by the wellbed beam template bracket;

[0173] 2) Master the well-beam is high, span, spacing, cross-sectional dimensions;

[0174] 3) Understand the type of site-based type and site drainage conditions;

[0175] 4) According to the above conditions and parameters, the well-beam template bracket construction drawing design is performed according to the wellbalm template bracket structure;

[0176] Second, carrying capacity verification:

[0177] 1) Determine the calculation unit:

[0178] The maximum pitch region of the beam side vertical rod 8 and the beam side vertical rod 8 in the wellbore beam span is a well-known...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com