Multi-layer filter screen tar collecting device cooled by utilizing refrigerating sheets, and tar collecting system

A collection device and refrigeration sheet technology, applied in coking ovens, petroleum industry, etc., can solve the problems of unable to measure the amount of tar, difficult to ensure high-efficiency cooling, difficult collection methods, etc., and achieve the effects of compact structure, expanded temperature range, and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Referring to the accompanying drawings, the multi-layer filter screen tar collection device and system for cooling by cooling fins involved in the present invention will be described in detail.

[0041]

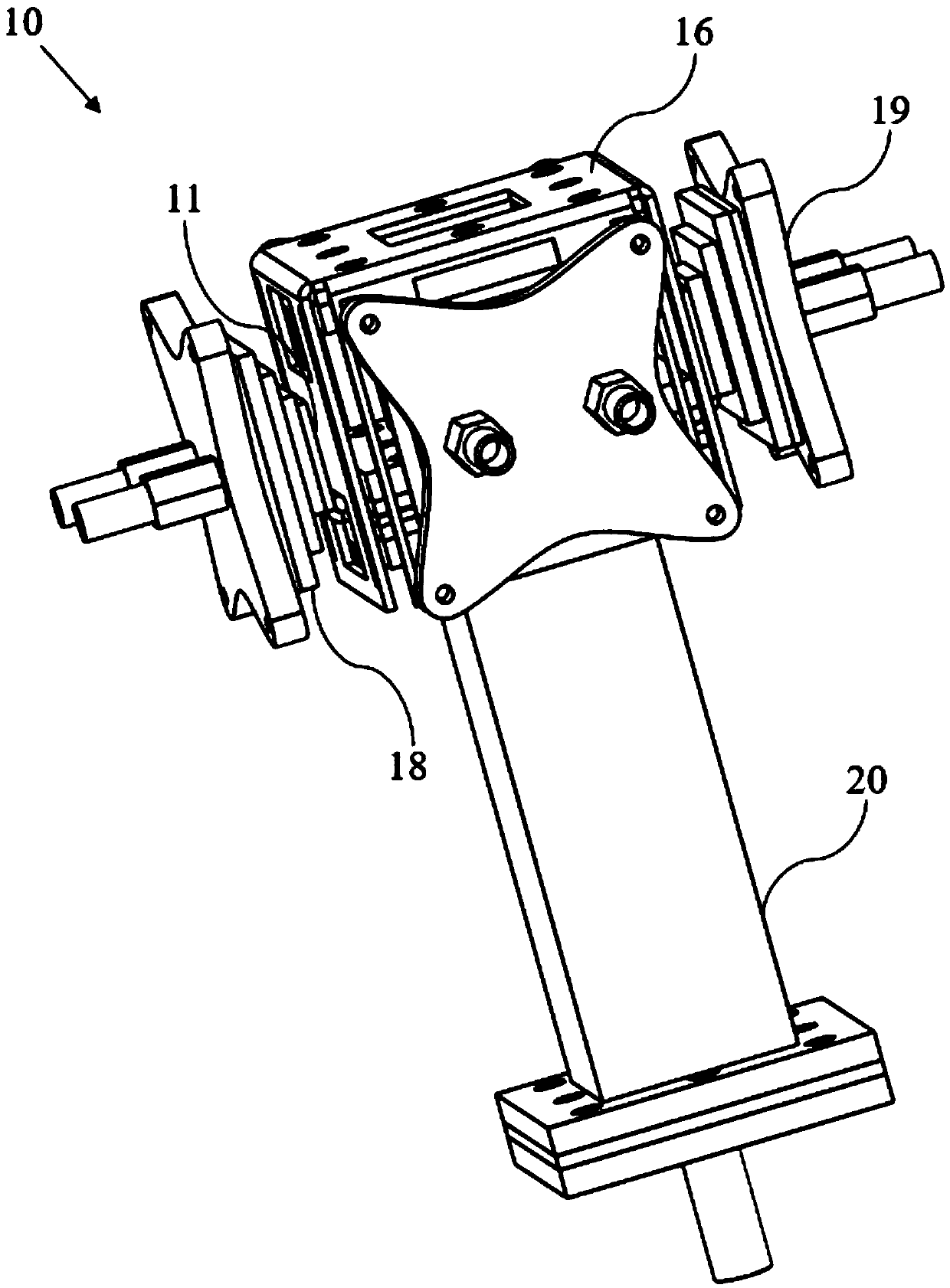

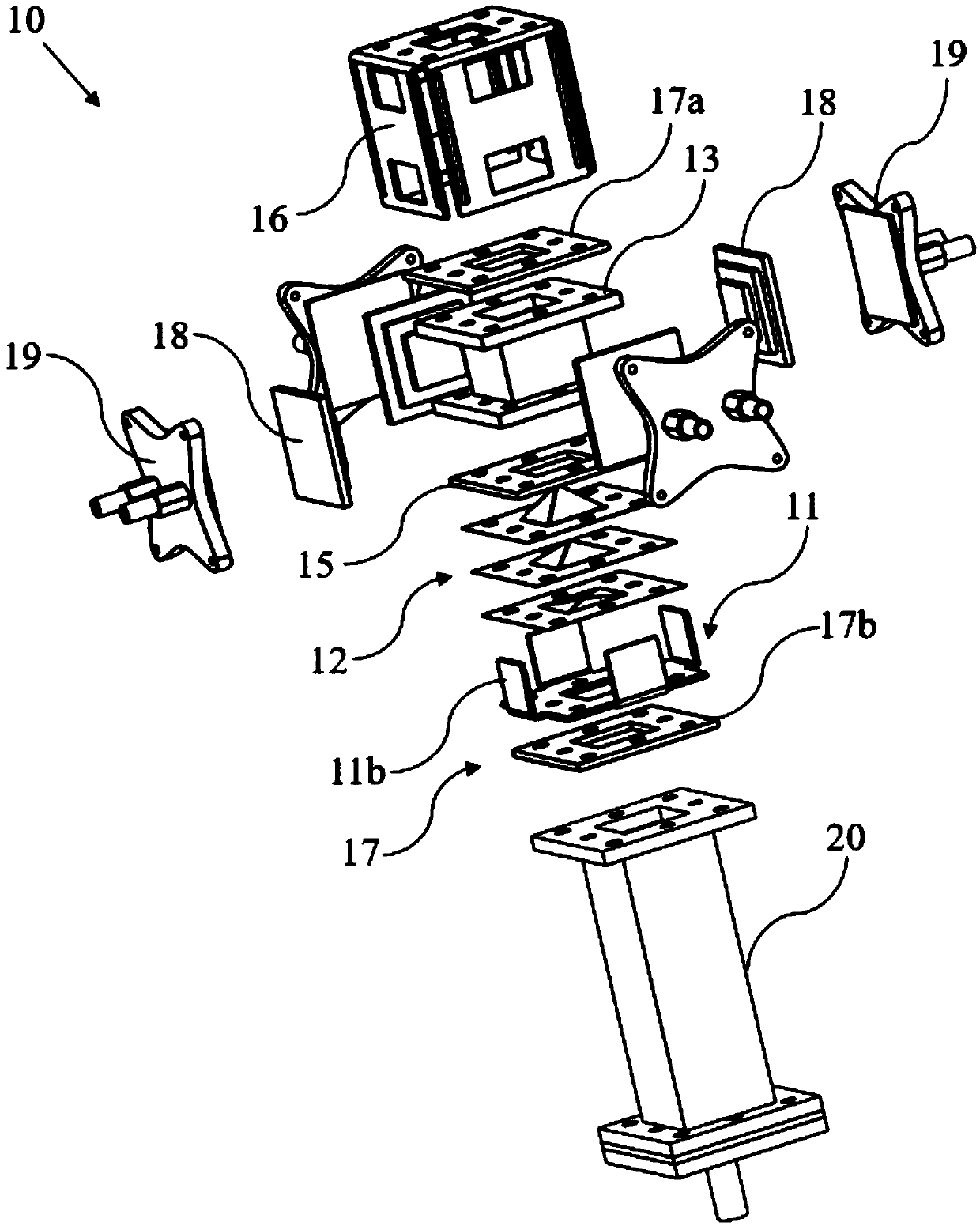

[0042] like figure 1 and 2 As shown, the multi-layer filter tar collecting device 10 communicates with the incoming pipeline 20 to condense the high-temperature pyrolysis gas delivered by the incoming pipeline 20 and collect the liquefied tar. The multi-layer filter tar collection device 10 includes a temperature guide sheet 11, a filter screen part 12, a connecting pipe 13, a perforated sieve plate 14, a graphite heat conduction patch 15, a support cover 16, a temperature insulation part 17, four refrigeration sheets 18, Four water cooling heads 19 and a temperature control assembly (not shown in the figure).

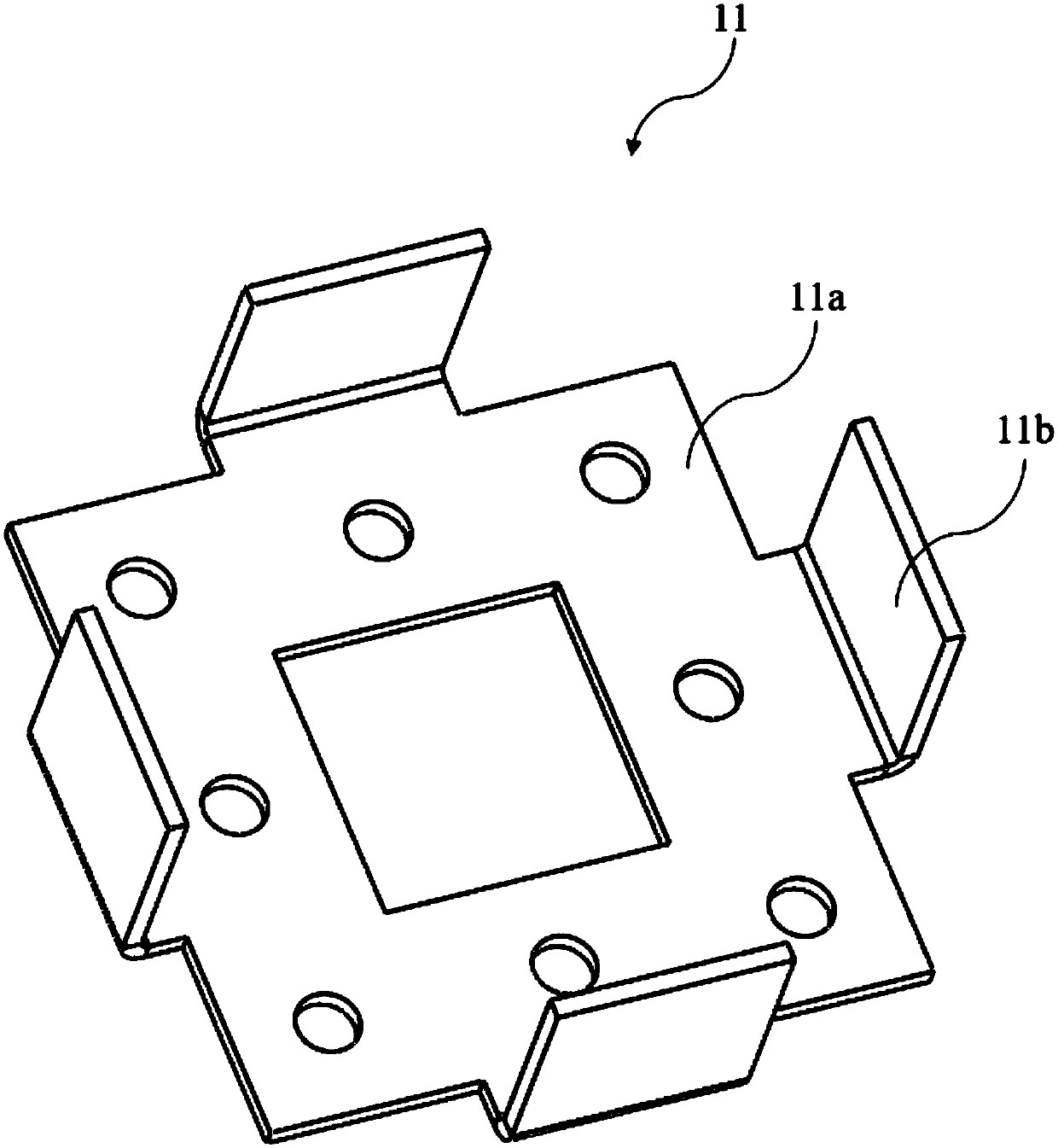

[0043] like image 3 As shown, the temperature-conducting sheet 11 is made of a metal material with excellent temperature-conducting performance, and it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com