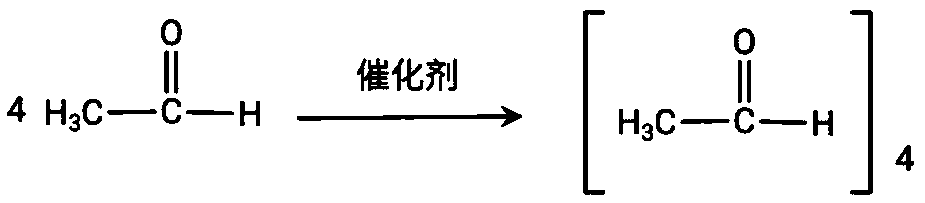

Synthesis method of metaldehyde

A synthetic method, metaldehyde technology, applied in the direction of organic chemistry, etc., can solve the problems of high acidity in the reaction environment, corrosive equipment, high cost consumption, etc., to simplify the synthesis process and operation steps, save time and cost, and achieve high efficiency. The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

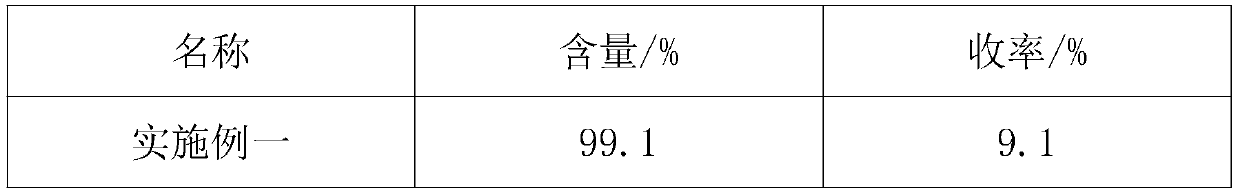

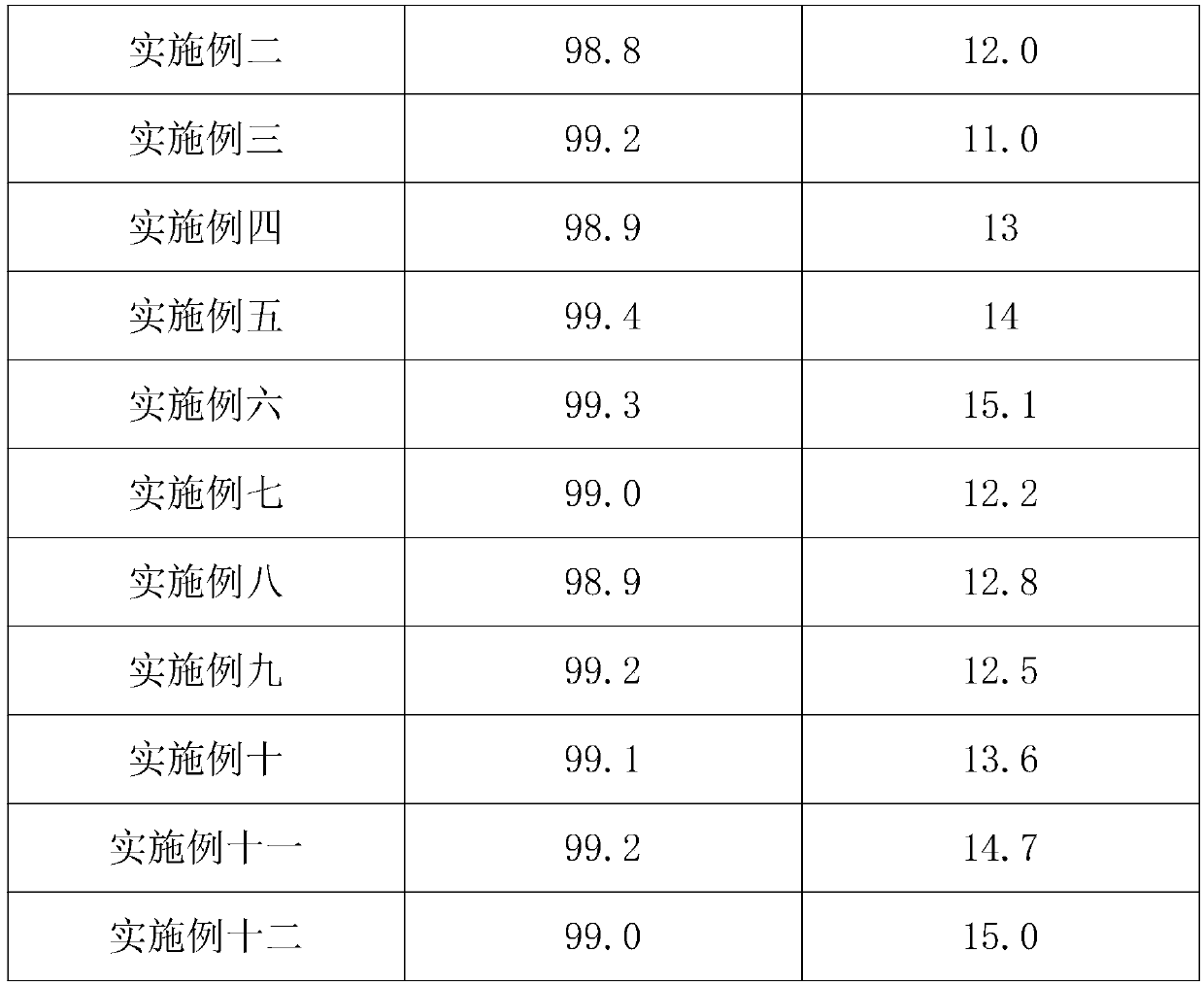

Embodiment 1

[0017] Put 50kg of acetaldehyde and 2.5kg of ether into the fixed-bed reactor filled with heterogeneous solid heteropolyacid-loaded cesium carbonate catalyst and the carrier as Mg-based SiO2, cool to -15°C, start the reaction, and control the temperature during the reaction At -10°C, filter after the reaction, wash the solid with water, and dry to obtain metaldehyde with a content of 99.1% and a yield of 9.1%. The filtrate is distilled, and sulfuric acid is added as a catalyst, the paraldehyde in the filtrate is depolymerized, acetaldehyde and ether are distilled and separated, and the next feeding is used for later use.

Embodiment 2

[0019] Put 20kg of acetaldehyde and 1kg of ether into the fixed-bed reactor filled with heterogeneous solid heteropolyacid-loaded catalyst tungstophosphoric acid, and the carrier is Mg-based SiO2, and cool to -10°C to start the reaction. During the reaction, the temperature is controlled at -5°C, filter after the reaction, wash the solid with water, and dry to obtain metaldehyde with a content of 98.8% and a yield of 12.0%. The filtrate is distilled, and sulfuric acid is added as a catalyst, the paraldehyde in the filtrate is depolymerized, acetaldehyde and ether are distilled and separated, and the next feeding is used for later use.

Embodiment 3

[0021] Put 40kg of acetaldehyde and 2kg of ether into the fixed-bed reactor filled with heterogeneous solid heteropolyacid-loaded catalyst tungstophosphoric acid, and the carrier is Mg-based SiO2, and cool to -5°C to start the reaction. During the reaction, the temperature is controlled at 0°C, filter after the reaction, wash the solid with water, and dry to obtain metaldehyde with a content of 99.2% and a yield of 11.0%. The filtrate is distilled, and sulfuric acid is added as a catalyst, the paraldehyde in the filtrate is depolymerized, acetaldehyde and ether are distilled and separated, and the next feeding is used for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com