Preparing method of high-magnetism low-loss soft magnetic ferrite material

A soft ferrite, low-loss technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., to save production costs, increase growth and density, and reduce losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

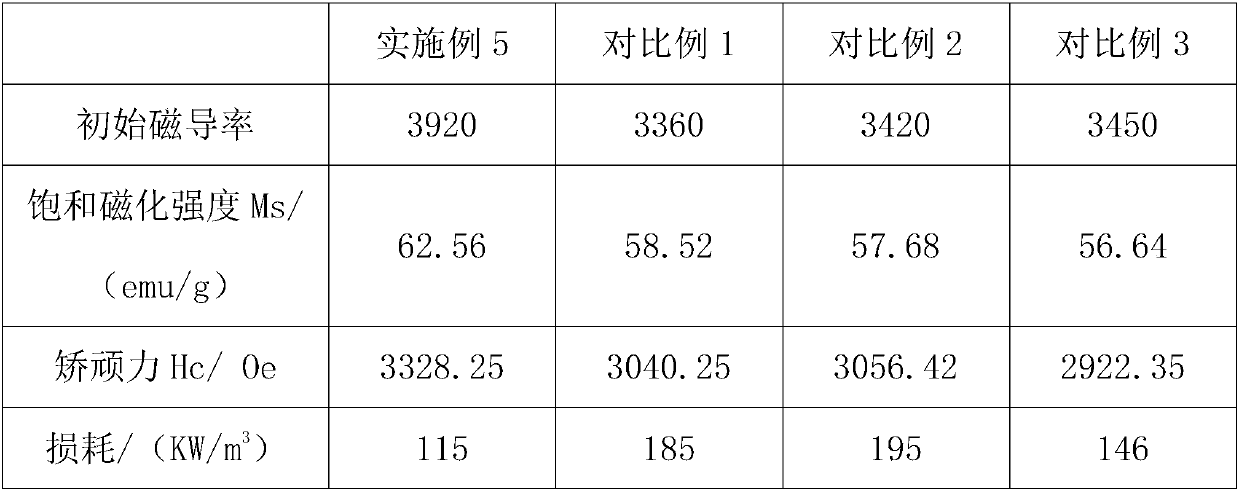

Examples

Embodiment 1

[0020] The preparation method of a kind of high magnetism low loss soft ferrite material that the present invention proposes, comprises the following steps:

[0021] S1, the Fe 2 o 3 、Ni 2 o 3 , Mn 3 o 4 , SnO 2 Mixing, ball milling once after adding water, and then drying to obtain material A;

[0022] S2, material A and MoO 3 、 Bi 2 o 3 Mixing, pre-burning and cooling to obtain material B;

[0023] S3, material B and TiO 2 , SiO 2 Mixing, adding water, performing secondary ball milling, and then drying to obtain material C;

[0024] S4. Mixing material C with polyvinyl alcohol aqueous solution and zinc stearate, granulating, and pressing to obtain material D;

[0025] S5. The material D is heated and sintered, and then cooled to room temperature to obtain a soft magnetic ferrite material with high magnetic properties and low loss.

Embodiment 2

[0027] The preparation method of a kind of high magnetism low loss soft ferrite material that the present invention proposes, comprises the following steps:

[0028] S1, by weight 80 parts of Fe 2 o 3 , 5 parts of Ni 2 o 3 , 12 parts of Mn 3 o 4 , 3 parts of SnO 2 After mixing, place it in a planetary ball mill, add water, perform ball milling once, and then dry at 110°C to obtain material A; wherein, the ball milling speed is 320r / min, and the ball milling time is 2h;

[0029] S2, by weight 120 parts of material A and 0.4 parts of nano-MoO 3 , 0.5 nanometer Bi 2 o 3 Mix, first raise the temperature to 420°C at a heating rate of 4°C / min, keep it warm for 40 minutes, then raise the temperature to 820°C at a heating rate of 2°C / min, pre-burn for 1.5 hours, and cool to room temperature to obtain material B;

[0030] S3, by weight 120 parts of material B and 0.5 part of nano TiO 2 , 0.4 parts of nano-SiO 2 After mixing, place it in a planetary ball mill, add water, perf...

Embodiment 3

[0034] The preparation method of a kind of high magnetism low loss soft ferrite material that the present invention proposes, comprises the following steps:

[0035] S1, by weight 90 parts of Fe 2 o 3 , 6.5 parts Ni 2 o 3 , 15 parts of Mn 3 o 4 , 4 copies of SnO 2After mixing, place it in a planetary ball mill, add water, perform ball milling once, and then dry at 115°C to obtain material A; wherein, the ball milling speed is 340r / min, and the ball milling time is 1.8h;

[0036] S2, by weight 135 parts of material A and 0.5 part of nanometer MoO 3 , 0.4 nano Bi 2 o 3 Mix, first raise the temperature to 430°C at a heating rate of 5°C / min, keep it warm for 35 minutes, then raise the temperature to 830°C at a heating rate of 3°C / min, pre-burn for 1.2 hours, and cool to room temperature to obtain material B;

[0037] S3, by weight 140 parts of material B and 0.6 parts of nano TiO 2 , 0.5 parts of nano-SiO 2 After mixing, place it in a planetary ball mill, add water, per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com