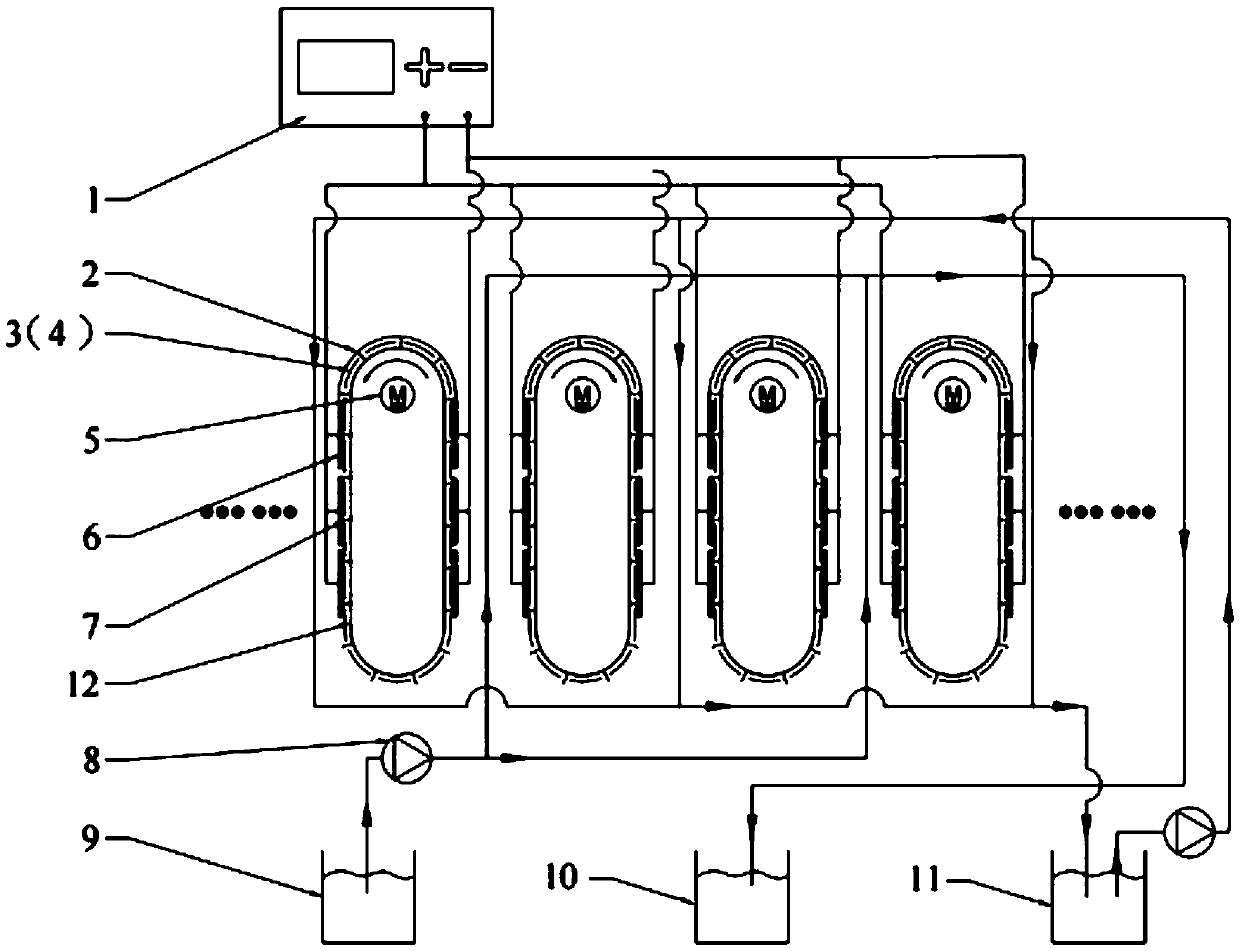

Rotary continuous capacitive deionizing desalting device

A technology of capacitive deionization and desalination device, applied in the field of desalination, can solve problems such as discontinuous production, and achieve the effects of low energy consumption, improved conversion rate, and improved desalination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

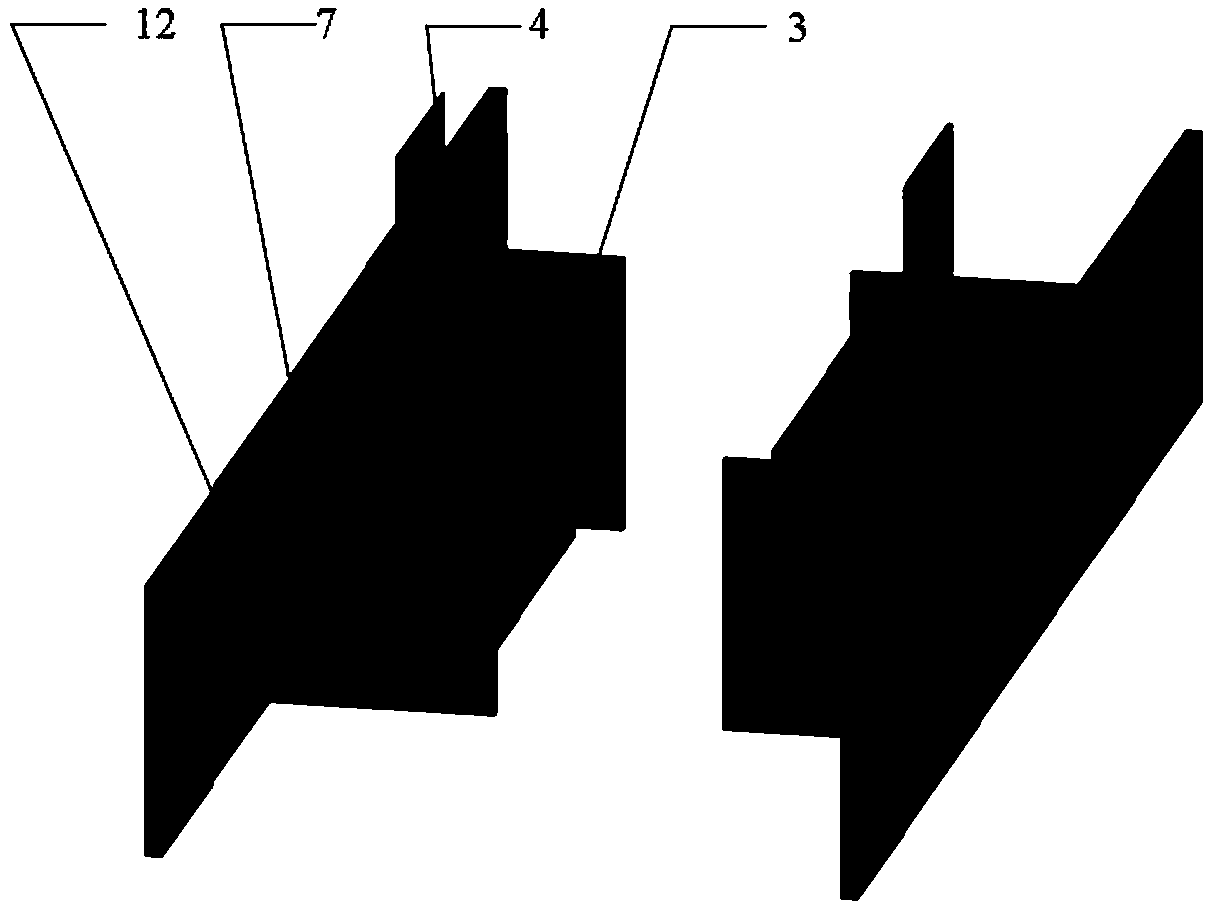

[0034] In Embodiment 1 of the present invention, the width of the conveyor belt 12 is 2 cm, the length of the straight section can be 10 cm, the radius of the bent section can be 10 cm, and the inside of the conveyor belt 12 is supported by a frame with a fixed shape. Multiple groups of conveyor belts 12 are placed side by side.

[0035] In Embodiment 1 of the present invention, the two adjacent groups of conveyor belts 12 rotate in opposite directions.

[0036] In Embodiment 1 of the present invention, the electrode 3 may have a thickness of 2 mm, a length consistent with the width of the conveyor belt 12, and a width of 0.5 mm. Its placement direction is that the length direction is consistent with the width direction of the conveyor belt 12 .

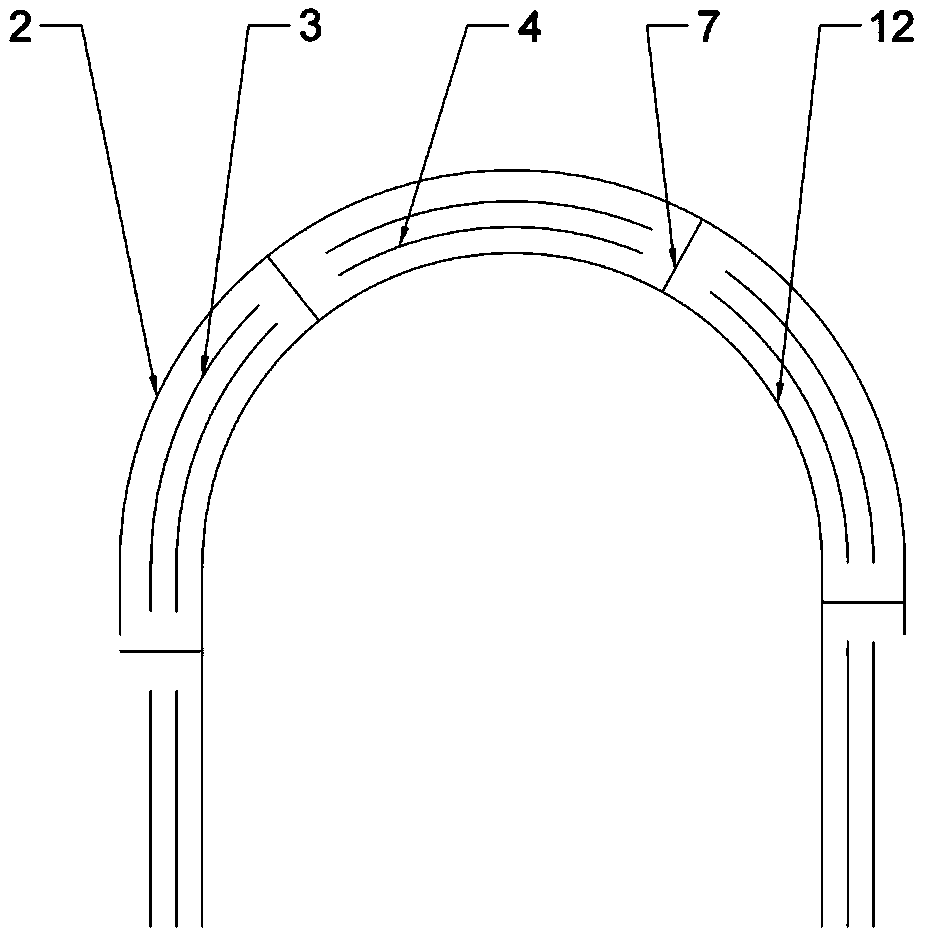

[0037] In Embodiment 1 of the present invention, the width of the semicircular baffle 2 is consistent with the width of the conveyor belt 12, and the radius of the semicircular baffle 2 is the radius of the bent section of the conve...

Embodiment 2

[0042] In Embodiment 2 of the present invention, the width of the conveyor belt 12 can be 7cm, the length of the straight section can be 100cm, and the radius of the bent section can be 30cm, and the interior of the conveyor belt 12 is supported by a fixed-shaped frame. Multiple groups of conveyor belts 12 are placed side by side.

[0043] In Embodiment 2 of the present invention, the two adjacent groups of conveyor belts 12 rotate in opposite directions.

[0044] In Embodiment 2 of the present invention, the electrode 3 may have a thickness of 4mm, a length consistent with the width of the conveyor belt 12, and a width of 6cm. Its placement direction is that the length direction is consistent with the width direction of the conveyor belt 12 .

[0045] In Embodiment 2 of the present invention, the width of the semicircular baffle 2 is consistent with the width of the conveyor belt 12, and the radius of the semicircular baffle 2 is the radius of the curved edge of the conveyor...

Embodiment 3

[0050] In Embodiment 3 of the present invention, the width of the conveyor belt 12 can be 5cm, the length of the straight section can be 300cm, the radius of the bent section can be 20cm, and the interior of the conveyor 2 is supported by a fixed shape frame. Multiple groups of conveyor belts 12 are placed side by side.

[0051] In Embodiment 3 of the present invention, the two adjacent groups of conveyor belts 12 rotate in opposite directions.

[0052] In Embodiment 3 of the present invention, the electrode 3 may have a thickness of 3mm, a length consistent with the width of the conveyor belt 12, and a width of 2cm. Its placement direction is that the length direction is consistent with the width direction of the conveyor belt 12 .

[0053] In Embodiment 3 of the present invention, the width of the semicircular baffle 2 is consistent with the width of the conveyor belt 12, and the radius of the semicircular baffle 2 is the radius of the curved edge of the conveyor belt 12 + ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com