Pulse electrolysis reactor and industrial sewage treatment system

A technology of pulse electrolysis and reactor, which is applied in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc. It can solve the problems of increased electrocoagulation energy consumption, increased cell voltage, plate passivation, etc. problem, to achieve the effect of reducing the amount of dissolution, reducing energy consumption, and reducing concentration polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

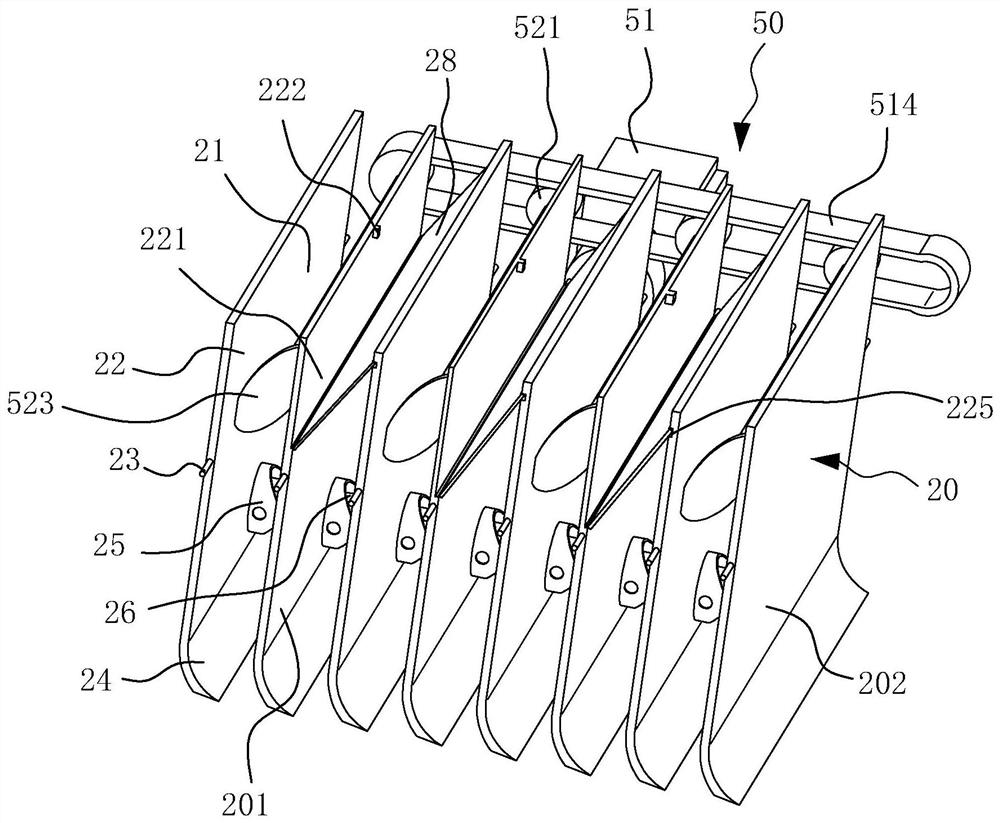

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0036] see figure 1 , a pulse electrolysis reactor 100, including an electrolytic cell body 10, a plurality of electrode plates 20 and a pulse power supply 30, an electrolysis space 15 is formed in the electrolytic cell body 10, and the plurality of electrode plates 20 are along the flow direction of sewage are arranged at intervals in the electrolysis space 15, so that sewage overflows from the bottom of each electrode plate 20 to the top of the electrode plate 20 to one of the electrode plates 20 downstream, and the pulse power supply 30 is electrically connected to at least two of the electrode plates 20, so that opposite sides of each of the electrode plates 20 have different polarities.

[0037]When the pulse electrolysis reactor 100 is in use, the sewage flows along the arrangement direction of the plurality of electrode plates 20, and the sewage overf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com