Special lifting appliance for rapidly hoisting tin groove bottom bricks of floating glass production line

A technology for tin bath bottom bricks and float glass, which is applied in the directions of transportation and packaging, load hanging components, etc., can solve the problem of long locking and decoupling operation time of tin bath bottom bricks, poor hoisting stability of tin bath bottom bricks, and tin bath bottom bricks. Problems such as the damage of the water chestnut of the bottom brick, to achieve the effect of convenient hooking and decoupling, saving decoupling time, and convenient welding and fabrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

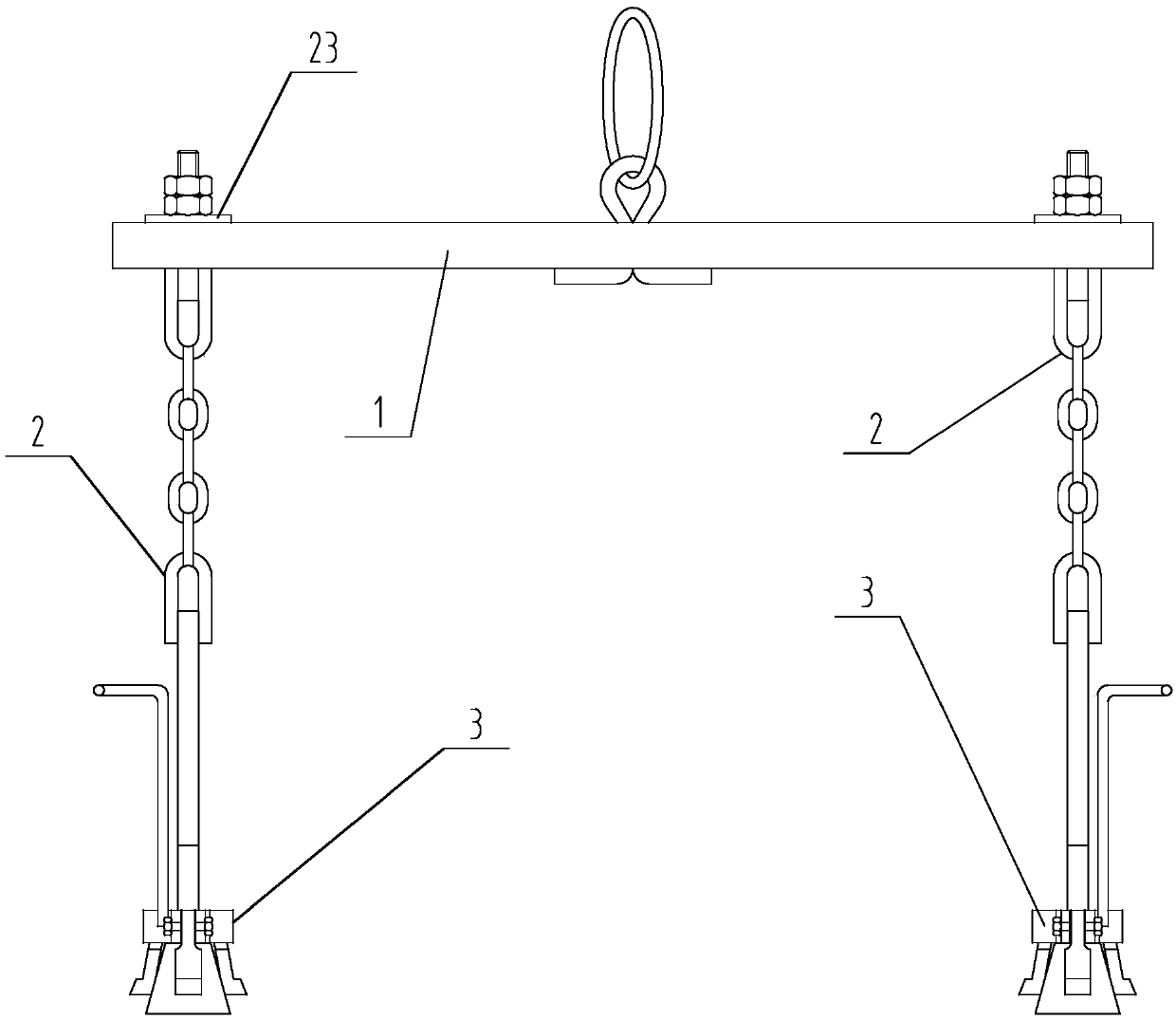

[0037] A special hoisting tool for quick hoisting of tin bath bottom bricks in a float glass production line, such as figure 1 As shown, it includes a main beam part 1, two boom parts 2 and two locking parts 3; each boom part 2 is paired with a locking part 3;

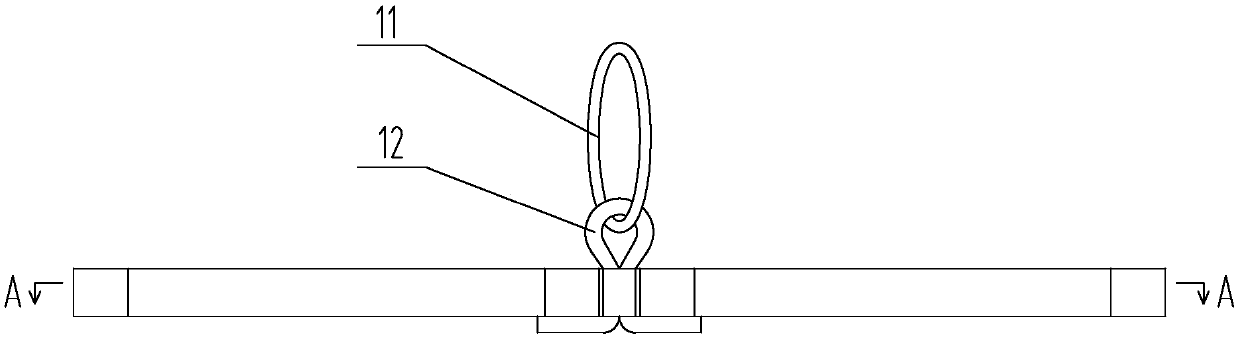

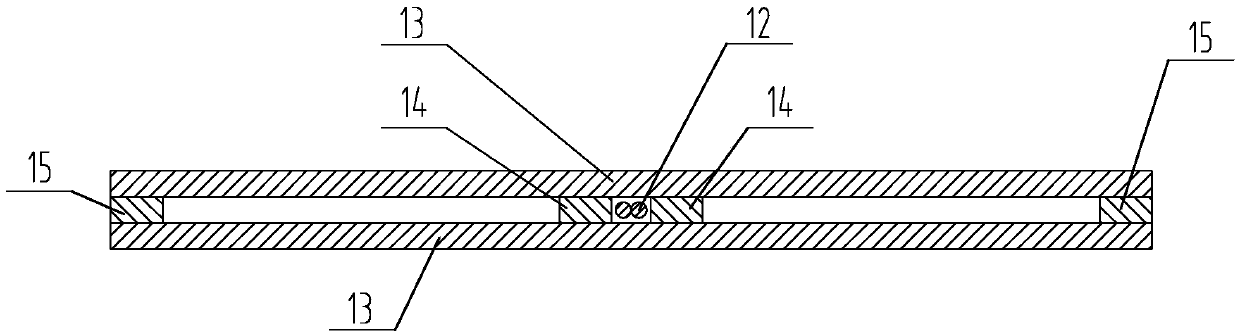

[0038] see figure 2 , image 3 , the main beam component 1 includes a steel wire rope 11, a round steel hook 12, a stressed steel plate 13, a partition steel plate 14 and a limit plate 15;

[0039] The stressed steel plates 13 are arranged symmetrically at parallel intervals, and mainly bear the hoisting load; the round steel hooks 12 are arranged at the parallel central positions of the stressed steel plates 13, and the partition steel plates 14 are symmetrically arranged on both sides of the round steel hooks 12. side and connected with the stressed steel plate 13, the partition steel plate 14 is mainly used to cut off and strengthen the strength of the stressed steel plate 13; the bottom of the round steel hook 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com