Plant-derived nylon master batch and preparation method thereof

A plant-sourced nylon technology, which is applied in the field of plant-sourced nylon masterbatch and its preparation, can solve the problems of affecting moisture absorption performance, easy broken filaments, and easy roll winding, so as to achieve fiber moisture absorption performance without weakening, stable production process, and traction. good stretch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

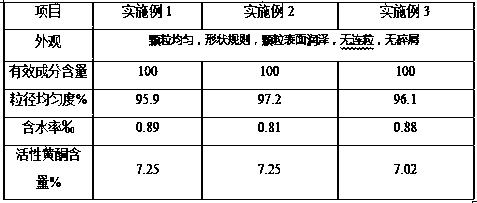

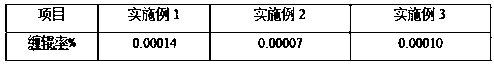

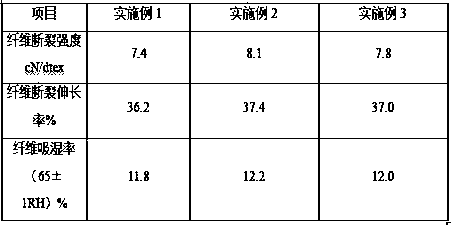

Embodiment 1

[0056] Embodiment 1 A kind of preparation method of grass coral plant source nylon masterbatch

[0057] Step 1, the preparation of modified grass coral extract

[0058] (1) Selection of raw materials

[0059] The extract of Coral praecox was selected as the plant source raw material of this embodiment, and 100% of the extract of Coral praecox passed through a 10,000 mesh sieve, the appearance of powder was loose, no agglomeration, the color was brownish yellow, and uniform; the content of active ingredients ≥ 98%, the content of isopyridine is 0.72%, the moisture content is ≤5%, the total number of colonies is less than 99cfu / g, Salmonella and Escherichia coli cannot be detected, and the shelf life is 18 months.

[0060] (2) Preparation of modified grass coral extract

[0061] Mix 65 parts of Grass coral extract with 25 parts of chitin and 7 parts of starch, adjust the pH to 8 with sodium carbonate, add 70 parts of deionized water and heat to 65°C and mix for 30 minutes, the...

Embodiment 2

[0087] Embodiment 2 A kind of preparation method of grass coral plant source nylon masterbatch

[0088] Step 1, the preparation of modified grass coral extract

[0089] (1) Selection of raw materials

[0090] The extract of Coral praecox was selected as the plant source raw material of this embodiment, and 100% of the extract of Coral praecox passed through a 10,000 mesh sieve, the appearance of powder was loose, no agglomeration, the color was brownish yellow, and uniform; the content of active ingredients ≥ 98%, the content of isopyridine is 0.72%, the moisture content is ≤5%, the total number of colonies is less than 99cfu / g, Salmonella and Escherichia coli cannot be detected, and the shelf life is 18 months.

[0091] (2) Preparation of modified grass coral extract

[0092] Add 21 parts of chitin and 6.5 parts of starch to 65 parts of Grass coral extract, mix, adjust the pH to 7.6 with sodium carbonate, add 64 parts of deionized water, heat to 63°C and mix for 30 minutes,...

Embodiment 3

[0118] Embodiment 3 A kind of preparation method of grass coral plant source nylon masterbatch

[0119] Step 1, the preparation of modified grass coral extract

[0120] (1) Selection of raw materials

[0121] The extract of Coral praecox was selected as the plant source raw material of this embodiment, and 100% of the extract of Coral praecox passed through a 10,000 mesh sieve, the appearance of powder was loose, no agglomeration, the color was brownish yellow, and uniform; the content of active ingredients ≥ 98%, the content of isopyridine is 0.72%, the moisture content is ≤5%, the total number of colonies is less than 99cfu / g, Salmonella and Escherichia coli cannot be detected, and the shelf life is 18 months.

[0122] (2) Preparation of modified grass coral extract

[0123] Add 15 parts of chitin and 4 parts of starch to 65 parts of Grass coral extract, mix, adjust the pH to 7 with sodium carbonate, add 50 parts of deionized water and heat to 50°C and mix for 30 minutes, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com