Gasket supplying system for C clamp automatic assembly

An automatic assembly and feeding system technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low work efficiency and large labor consumption, and achieve the effect of ensuring smooth progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

[0021] Such as Figure 1-Figure 4 A gasket feeding system for automatic assembly of a C-type card is shown, including

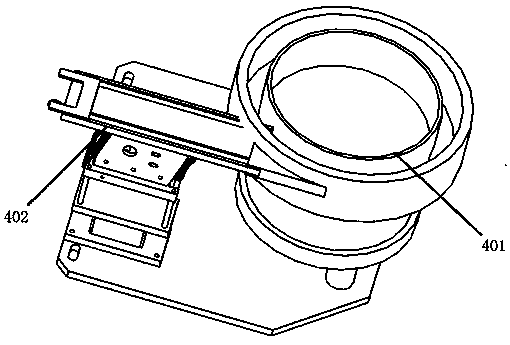

[0022] A gasket feeding assembly, the gasket feeding assembly includes a gasket screw vibrating feeder 401 .

[0023] A gasket conveying assembly, the gasket conveying assembly includes a gasket conveying support 402, a gasket conveying belt is installed on the gasket conveying support 402, the feeding end of the gasket conveying belt and the gasket screw vibrating feeder 401 The discharge port is connected.

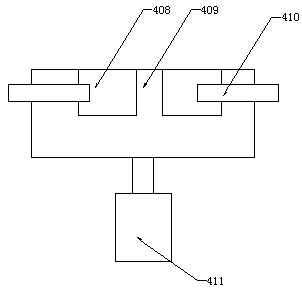

[0024] A gasket baffle plate is also installed on the gasket conveying bracket 402, and the gasket baffle plate includes a gasket upper baffle plate 406 located above the gasket conveyor belt and a gasket upper baffle plate 406 connected to the gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com