Integrated sulphur pulverizing device

A pulverizing device and integrated technology, applied in the field of integrated sulfur pulverizing device, can solve the problems of sulfur powder flow escape, environmental pollution and production safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Attached below Figure 1-4 The present invention is further described with embodiment:

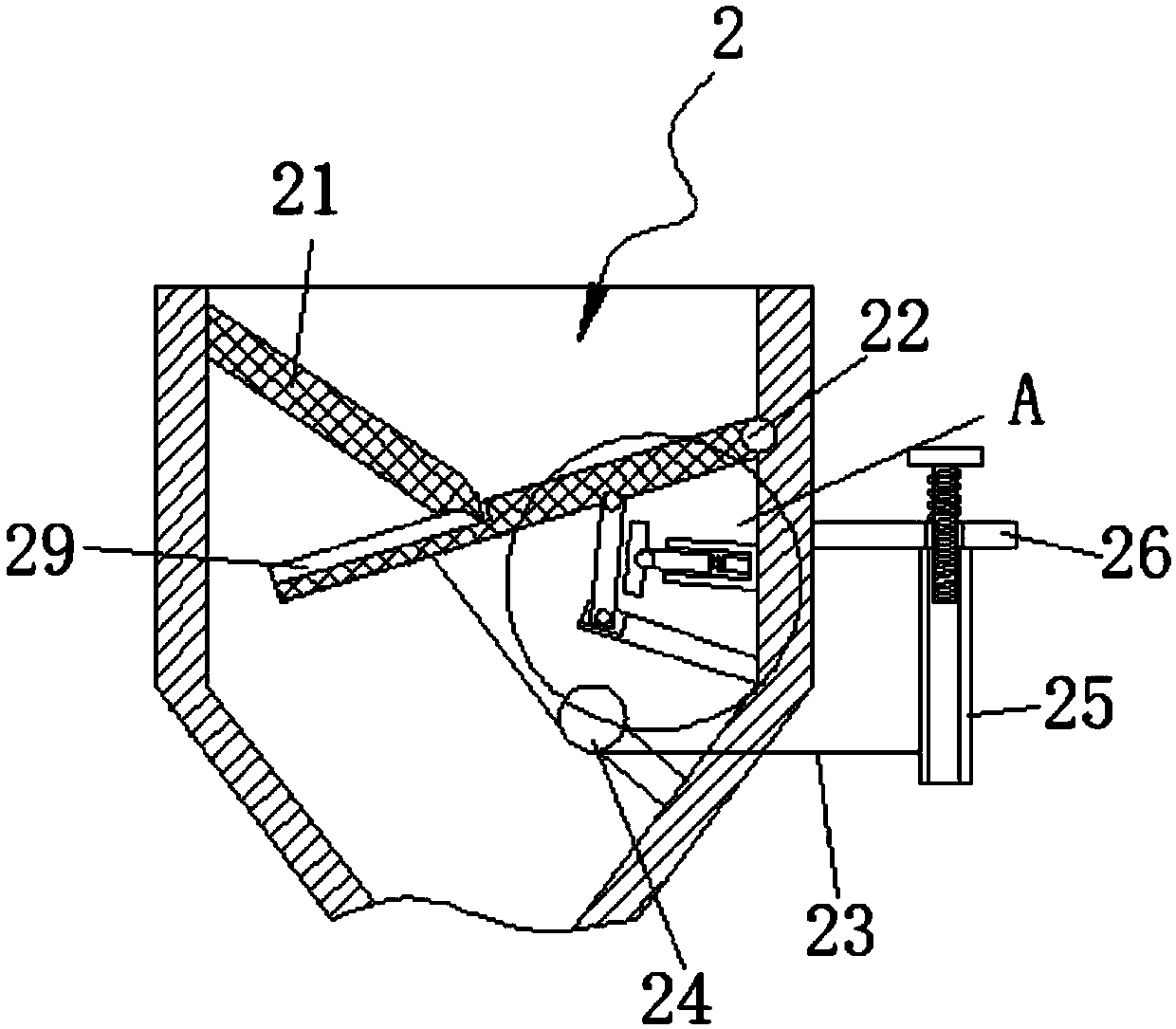

[0024] An integrated sulfur crushing device, comprising a crushing box 1 and a feed trough 2, the upper end of the crushing box 1 is provided with a feed trough 2, the lower end of the crushing box 1 is also provided with a discharge port 3, and the crushing box 1 1 is also provided with a support rod 4 on the outer box body, and the inner wall of the feeding trough 2 is connected with a fixed sealing plate 21 and a rotating sealing plate 22, and the fixed sealing plate 21 and the rotating sealing plate 22 are matched and arranged, and the rotating sealing The lower end of the plate 22 is connected with a steel rope 23, and the steel rope 23 bypasses the fixed pulley 24 and extends to the outside of the feeding trough 2 and is wound and connected to the threaded pipe 25. The fixed pulley 24 is rotatably connected to the inner side wall of the feeding trough 2 , the threaded pipe 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com