Adsorption film based on metal organic framework material, preparation method and application

A metal-organic framework, adsorption membrane technology, applied in chemical instruments and methods, adsorption water/sewage treatment, special compound water treatment, etc. , Excellent adsorption and removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

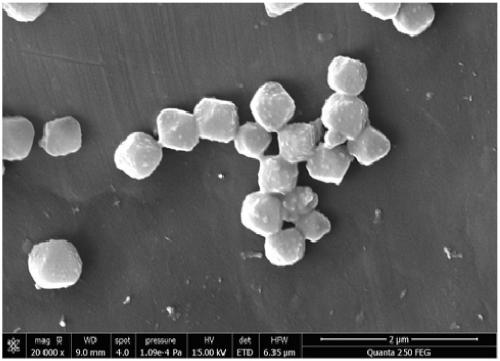

Image

Examples

Embodiment 1

[0048] The preparation process of adsorption membrane in the present embodiment comprises the following steps:

[0049] 1) Add 100mg Fe 3 o 4 @MIL-53 granular material was added to ethanol, and ultrasonically mixed for 30 minutes to obtain a dispersion liquid. The Fe 3 o 4 The dosage of @MIL-53 granular material is 25wt%.

[0050] Fe in this example 3 o 4 The synthesis steps of @MIL-53 granular material are as follows:

[0051] a) Prepare solution A: ZrCl 4 and H 2 BDC was ultrasonically dissolved in DMF, and MIL-53 was added for ultrasonic dispersion;

[0052] b) Preparation of solution B: ultrasonically dissolve PVP (K30) in DMF, then add Fe 3 o 4 ultrasonic dispersion;

[0053] c) Mix solutions A and B, ultrasonically disperse, and shake in a water bath under heating conditions.

[0054] d) washing with methanol, centrifugation, and vacuum drying to obtain Fe 3 o 4 @MIL-53 granular material.

[0055] 2) Add polyvinylidene fluoride to N,N-dimethylacetamide, mi...

Embodiment 2

[0061] The preparation process of adsorption membrane in the present embodiment comprises the following steps:

[0062] 1) Add 300mg Fe 3 o 4 @UiO-66 granular material was added to acetone, and ultrasonically mixed for 30 minutes to obtain a dispersion liquid. The Fe 3 o 4 The dosage of @UiO-66 granular material is 50wt%.

[0063] 2) Add 200mg of polyvinylidene fluoride to N,N-dimethylformamide, mix well with ultrasonic for 30min and dissolve it completely, then use it as casting liquid, mix the casting liquid with the above dispersion liquid, and mix thoroughly with ultrasonic for 30min , to obtain a blend solution, the polymer content in the casting solution in this step is 20wt%; the volume ratio of the dispersion liquid and the casting solution in the blend solution is 2:1.

[0064] 3) Heating at 60°C for 24 hours, evaporating to remove the acetone, coating the obtained blend on the glass plate substrate with a micron adjustable membrane device, and removing the organi...

Embodiment 3

[0070] The preparation process of adsorption membrane in the present embodiment comprises the following steps:

[0071] 1) Add 50mg Fe 3 o 4 @UiO-66 granular material was added to methanol, and ultrasonically mixed for 30 minutes to obtain a dispersion liquid. The Fe 3 o 4 The dosage of @UiO-66 granular material is 60wt%.

[0072] 2) Add 150mg of polyacrylonitrile into N,N-dimethylformamide, mix thoroughly and evenly by ultrasonication for 30min and completely dissolve it as a casting solution, mix the casting solution with the above dispersion solution, and mix well by ultrasonication for 30min, The blend liquid is obtained, and the content of the polymer in the casting liquid in this step is 40 wt %; the volume ratio of the dispersion liquid and the casting liquid in the blend liquid is 6:1.

[0073] 3) Heating at 50° C. for 24 hours, and evaporating methanol therein. Scrape the obtained blend solution on a polytetrafluoroethylene plate with a micron-adjustable membrane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com