Mixing and stirring integrated facility for producing and processing semi-conductive materials

A semi-conductive and facility technology, which is applied in the field of mixing and stirring integrated facilities, can solve the problems of poor defoaming effect, many bubbles, and poor heating and mixing effect of semi-conductive raw materials, so as to ensure the effect of later use, ensure the quality of mixing, and improve The effect of mixing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

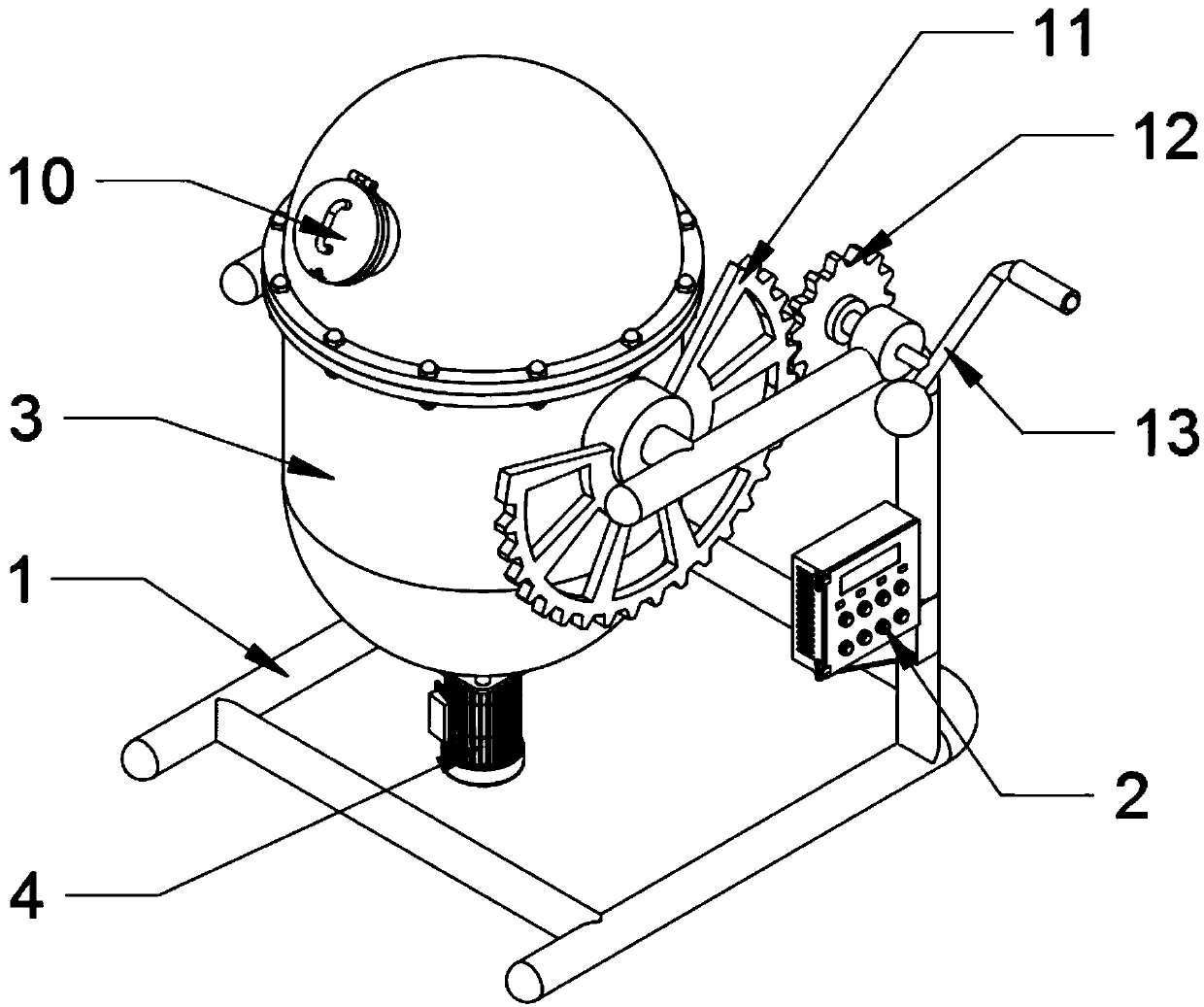

[0031] as attached figure 1 to attach Figure 8 Shown:

[0032] The invention provides an integrated mixing and stirring facility for the production and processing of semi-conductive materials, including a support base 1, a power control box 2, a mixing tank 3, a feeding port 301, a stirring motor 4, a mixing shaft 5, and a stirring frame 6 , stirring blade 7, heating ring 8, vibration motor 9, sealing cover 10, driven wheel 11, driving wheel 12 and manual crank 13; the power control box 2 is installed on the right side of the support base 1, and the support base 1 is a frame structure, and the mixing tank 3 is installed in the top of the support seat 1; the inside of the mixing tank 3 is a hollow structure, and the top of the mixing tank 3 is provided with a feeding port 301; the stirring motor 4 is installed in the mixing tank 3 on the bottom end face, and the stirring motor 4 is electrically connected to the power control box 2 through the power line; the bottom of the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com