Paper Insertion Machine for Iron Core Embedded Groove

A technology of embedding wire grooves and paper inserting machines, which is applied in the direction of laying solid insulation, etc., and can solve problems such as affecting the quality of the rotor, loose fit, and slow machine operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

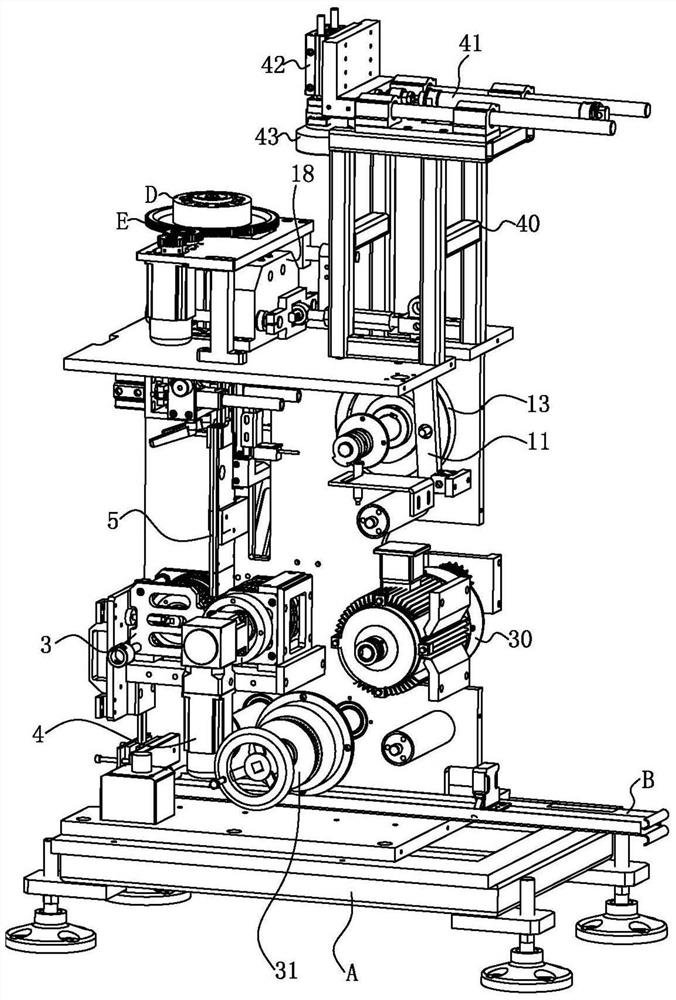

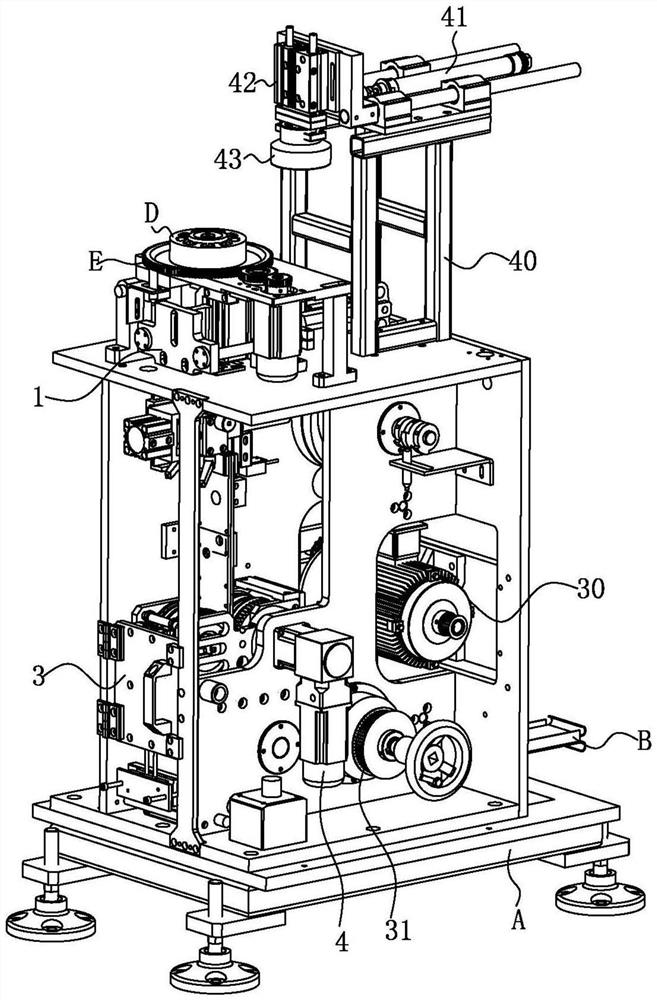

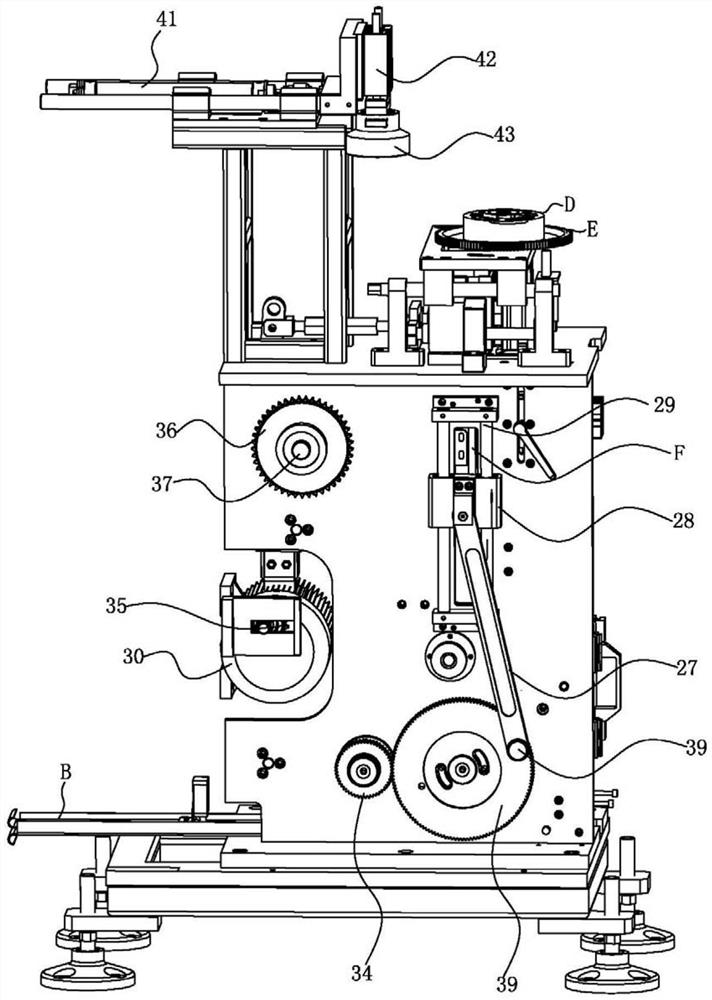

[0038] Such as Figure 1 to Figure 3 As shown, the paper insertion machine of the iron core embedding groove of the present invention includes an indentation mechanism, a paper passing mechanism, a paper cutting and pressing mechanism, a forming die, a paper pushing mechanism, and a first driving mechanism. Each part and their The relationship between them is described in detail:

[0039] Such as Figure 1 to Figure 3 As shown, there is a paper guide assembly B on the frame A, a paper frame (not shown in the figure) is provided on one side of the frame A, a channel is provided on the paper guide assembly B, and insulating paper C passes through the paper guide assembly B After entering the creasing mechanism, the paper guide assembly B guides the insulating paper C on the paper holder. The iron core D has multiple wire embedding grooves, and multiple angles are formed in each wire embedding groove.

[0040] Such as Figure 1 to Figure 3 As shown, the indentation mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com