Welding-free furniture structure

A technology without welding and furniture, which is applied in the direction of furniture connection, connection components, rod connection, etc., can solve the problems of environmental human impact, space occupation, etc., and achieve the effect of solving accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

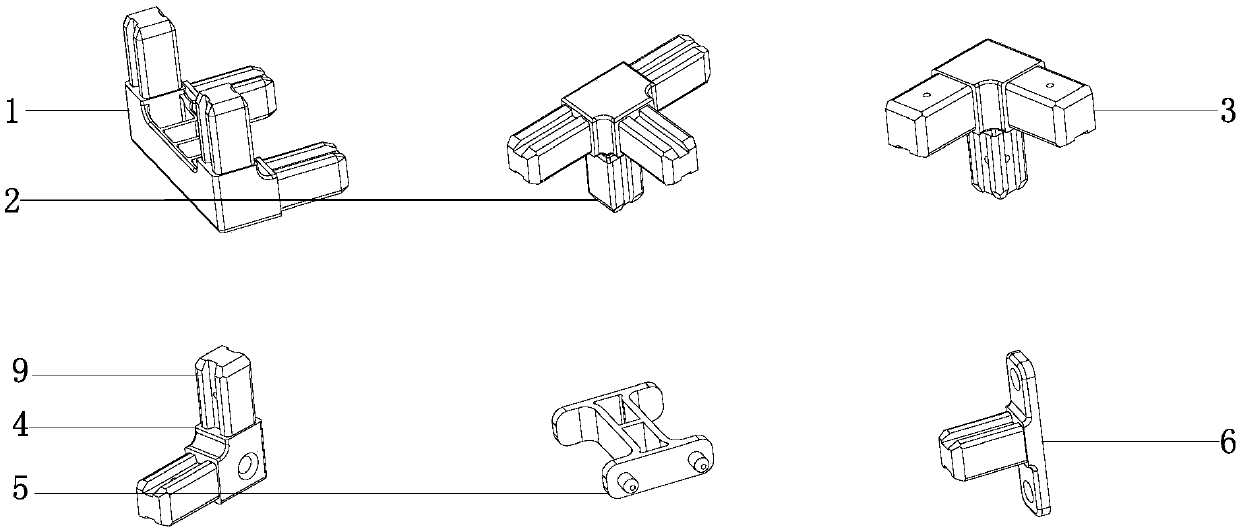

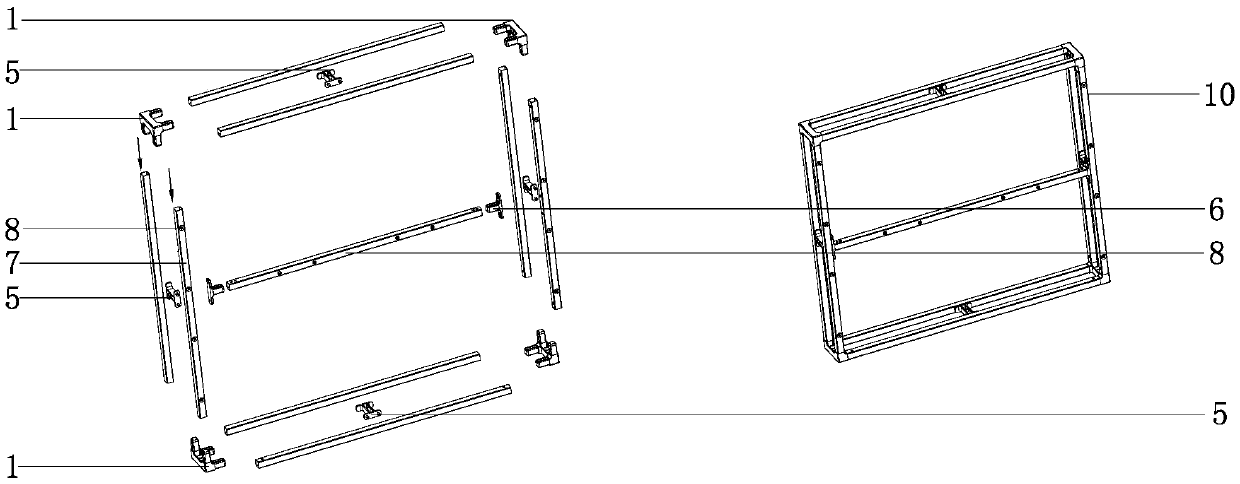

[0032] A furniture structure without welding, which mainly includes a pipe body 7 and a connecting piece, wherein the connecting piece is specifically as figure 1 The four-way piece 1, the three-way piece 3, the two-way piece 4, the support piece 5 and the T-shaped connector 6 are shown; the pipe body 7 is a hollow pipe with openings at both ends. The outside of the piece 5 is a larger joint, which can be inserted into the opening of the pipe body 7 to cooperate with it; the joints of the support piece 5 are 4 smaller joints located at corresponding positions on both sides of the pipe body. 7 is provided with a corresponding hole on the pipe wall, and the joint of the support member 5 can be inserted into the hole to cooperate with the pipe body 7; in this way, the pipe body 7 and the pipe body 7 can be combined through the connector, so that The effect of combined assembly without welding is achieved.

[0033] In this example, if figure 2 As shown in the pipe body 7, a lim...

Embodiment 2

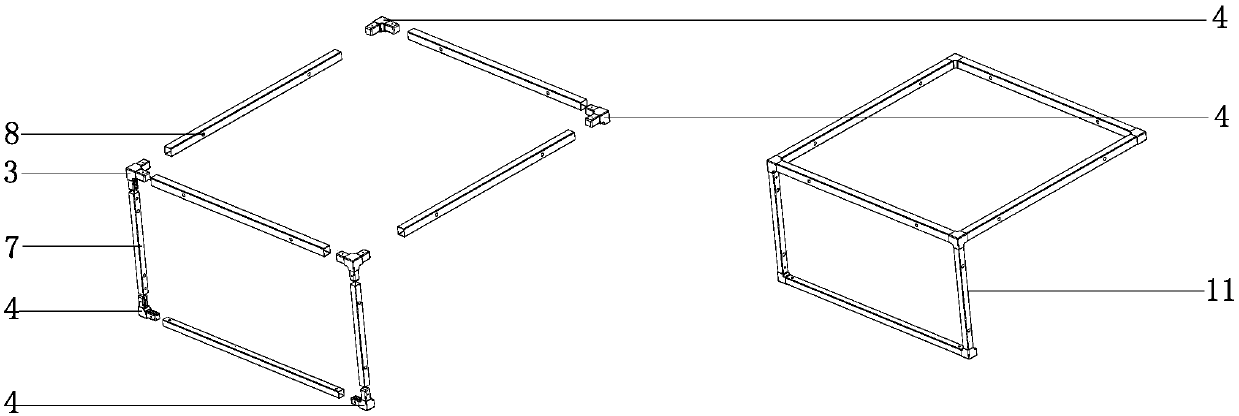

[0039] The difference between this embodiment on the basis of Embodiment 1 is that this embodiment includes the following Figure 4 As shown in the frame C12, the frame C12 is specifically a rectangular frame composed of 8 pipe bodies 7 coupled with 4 three-way pieces 3 and 3 two-way pieces 4 connected to each other, and a frame surface is surrounded by four pipe bodies 7 According to the description, among the four sides of the rectangular frame, two adjacent sides are frameless surfaces, and two adjacent side surfaces opposite to it are framed surfaces.

[0040] In this example, if Figure 8 The two frames A10 shown in the vertical state perpendicular to each other are respectively arranged on the two frameless surfaces of the frame C12, and between the frames A10 and the frame A10, and between the frame A10 and the frame C12 are all passed through intersecting The pipe bodies 7 are mated and connected, and the installation holes 19 at the intersections of the pipe bodies 7...

Embodiment 3

[0042] The difference between this embodiment on the basis of Embodiment 1 is that this embodiment includes the following Figure 5As shown in the frame D13, the frame D13 is specifically a rectangular frame composed of 11 pipe bodies 7 and 6 three-way pieces 3 and two two-way pieces 4 connected to each other, and four pipe bodies 7 form a frame surface According to the description, one of the four sides of the rectangular frame is a frameless surface, and the rest are all framed surfaces.

[0043] In this example, if Figure 9 The furniture C shown is an armless sofa frame composed of a frame D13 and a vertically placed frame A10, wherein the frame A10 and the frame D13 are connected to each other through the pipe body 7, and the intersecting pipe body 7 The positions corresponding to the body 7 are provided with installation holes 19, through which screws pass through the installation holes 19 to realize the combined assembly between the frames, thereby completing the assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com