A atomization humidification and dust suppression equipment for environmental engineering site construction

An atomization humidification and on-site construction technology, which is applied in the processing of building materials, construction, cleaning methods, etc., can solve the problems that the construction area cannot be fully atomized and humidified, the coverage area of atomization and humidification is small, and the soil is prone to dust. Ensure the effect of humidification and dust suppression, ensure the effect of water supply, and improve the effect of spray coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

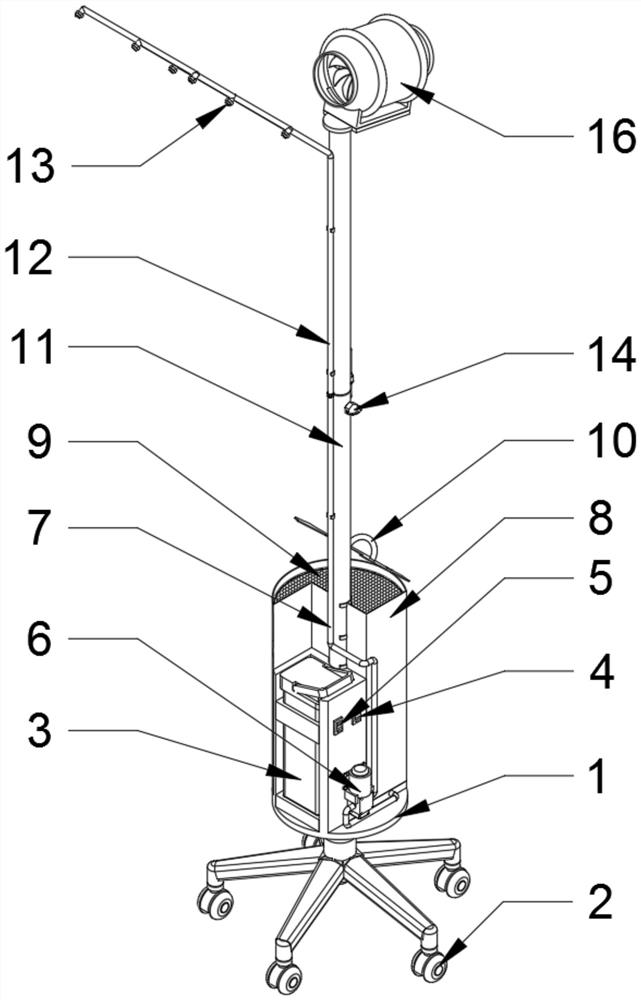

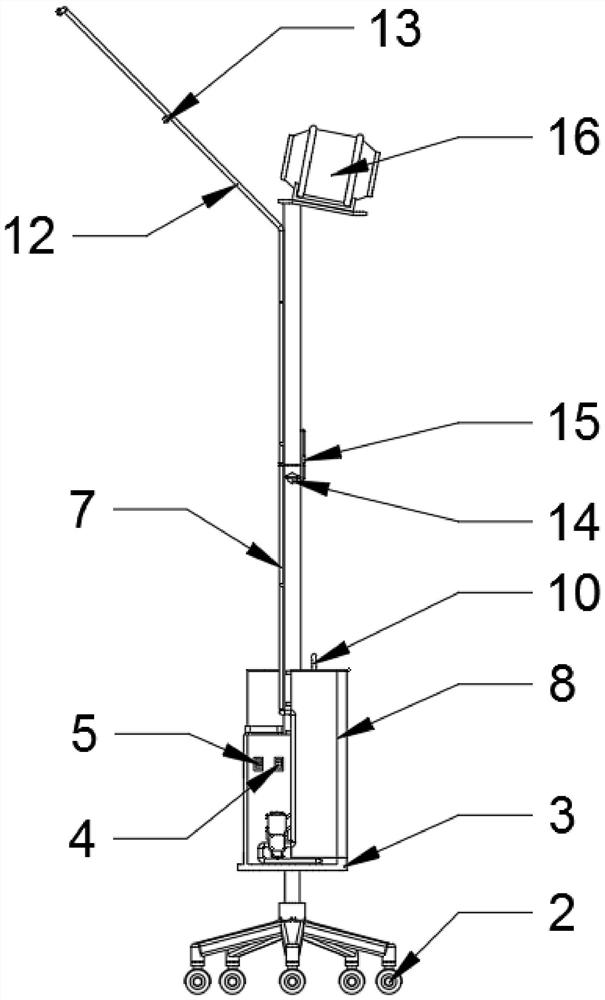

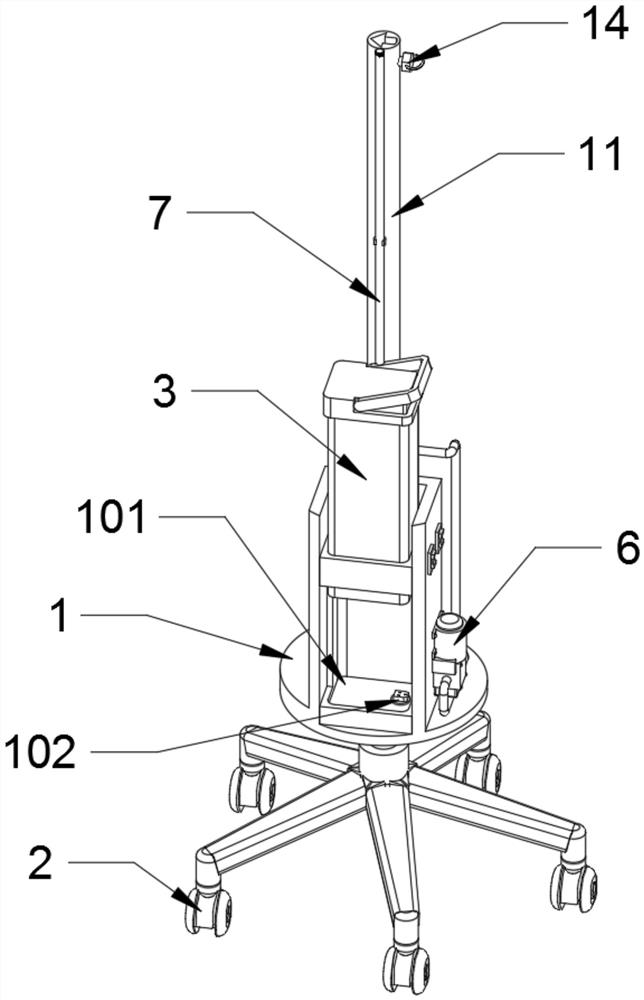

[0035] as attached figure 1 to attach Figure 10 Shown:

[0036]The invention provides an atomization, humidification and dust suppression equipment for environmental engineering site construction, including a base 1, a lithium battery placement slot 101, a main power supply socket 102, a universal wheel 2, a lithium battery 3, a power supply plug 301, and a water pump control switch 4 , fan control switch 5, small high-pressure pump 6, water supply pipe 7, water storage tank 8, filter screen 9, box cover 10, support column 11, spray pipe 12, threaded connection cap 1201, atomizing nozzle 13, fixing bolt 14, power supply Connector 15 and fan 16; the lithium battery 3 is installed on the bottom of the base 1, and a power supply plug 301 is provided at the bottom of the lithium battery 3, and the power supply plug 301 is connected to the water pump control switch 4 and the fan control switch through the main power supply jack 102 respectively. The water pump control switch 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com