Electrolyzed water reaction device with externally applied magnetic field and method for improving electrocatalytic properties

A technology of applying an external magnetic field and a reaction device, applied in the electrolysis process, electrolysis components, electrodes, etc., can solve the problems of oxygen evolution and hydrogen evolution performance that are not involved in the field of electrolysis water, and achieve the effect of improving performance and improving catalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

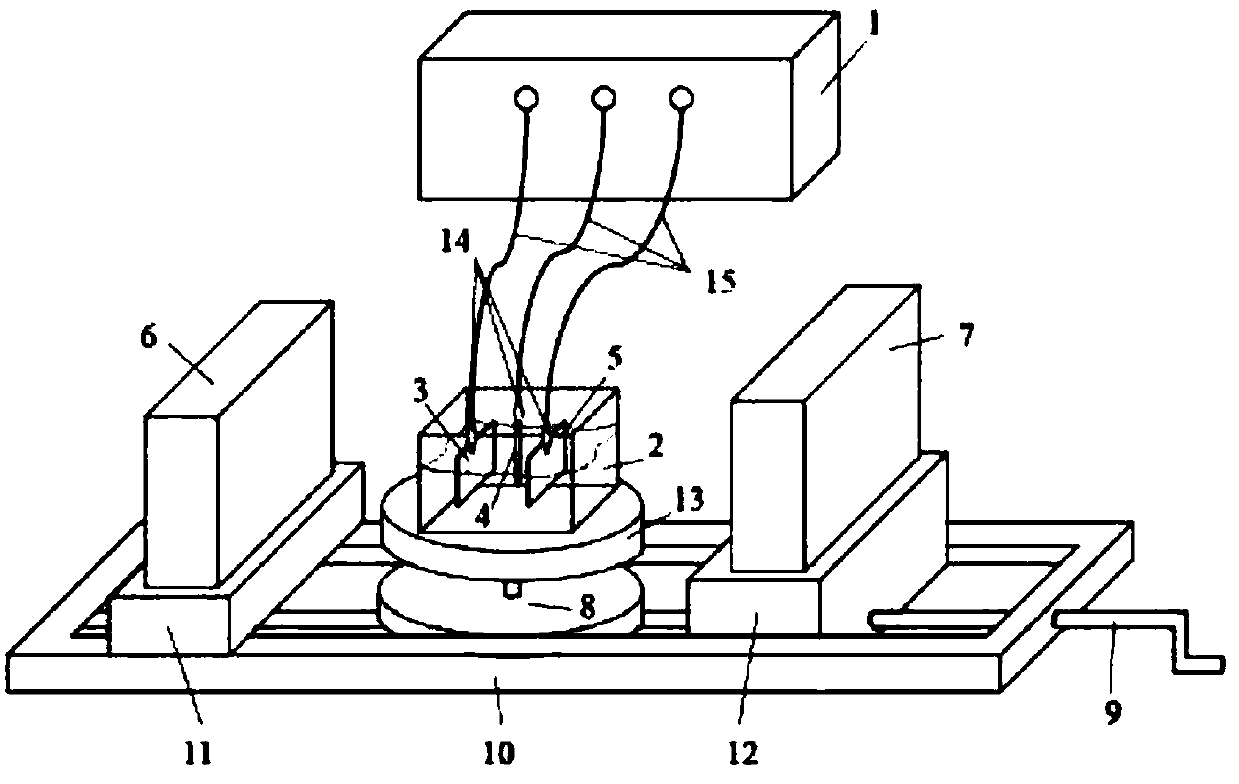

[0052] A layer of cobalt-containing precursor material was grown on the foamed Ni by the hydrothermal method, and then heat-treated at 400 °C in an air atmosphere for 4 hours, and finally the Co grown directly on the foamed Ni was obtained. 3 o 4 catalyst. The surface will be grown with Co 3 o 4 The Ni foam of the catalyst was used as the working electrode, and the CHI 760E electrochemical workstation was used to characterize the oxygen evolution performance of the catalyst in electrolysis of water, which was carried out in a three-electrode system electrolyzer at room temperature. Among them, the electrolyte is 1M KOH solution, the counter electrode is Pt sheet, and the reference electrode is Ag / AgCl electrode. The electrochemical behavior is mainly analyzed using linear sweep voltammetry (LSV) curves and Tafel curves, and the scanning speed of LSV is always set to 5mV / s.

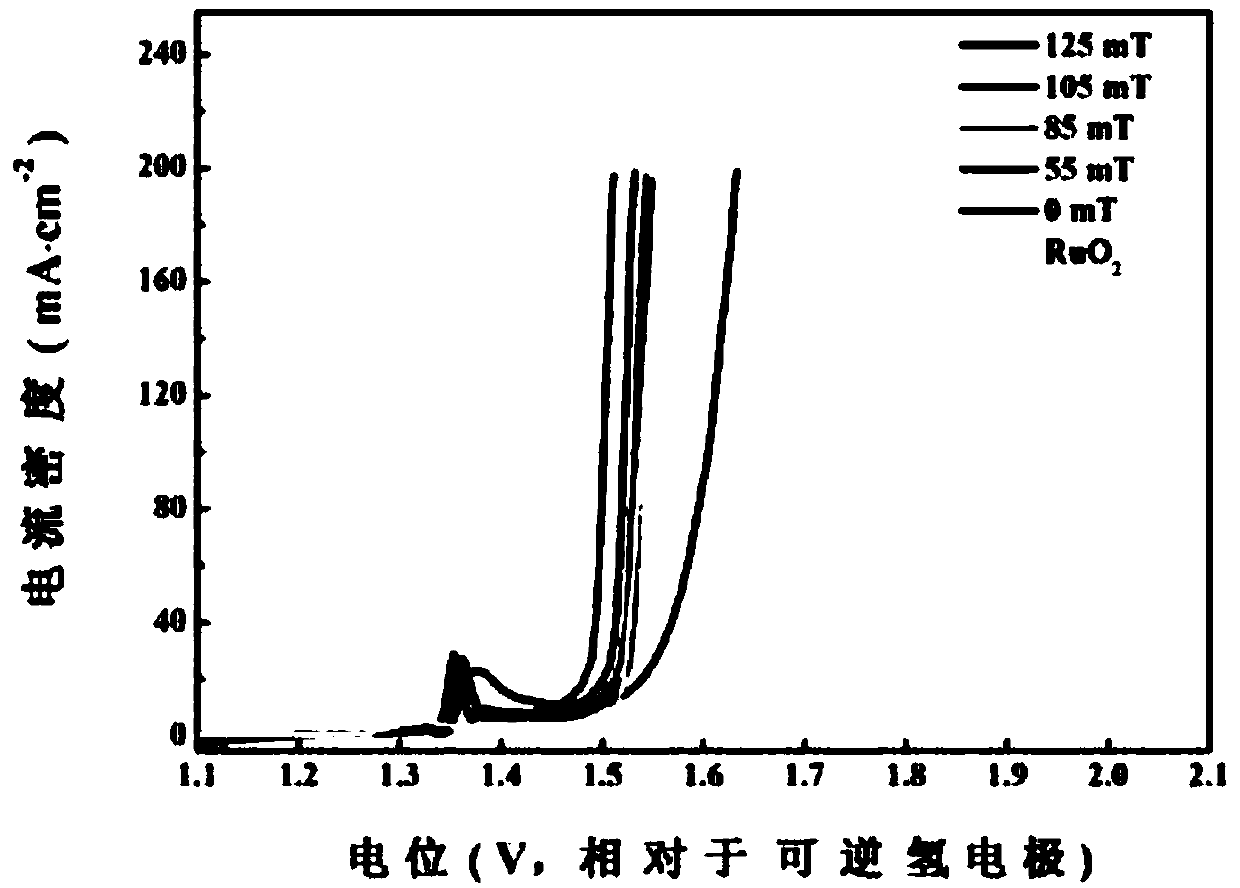

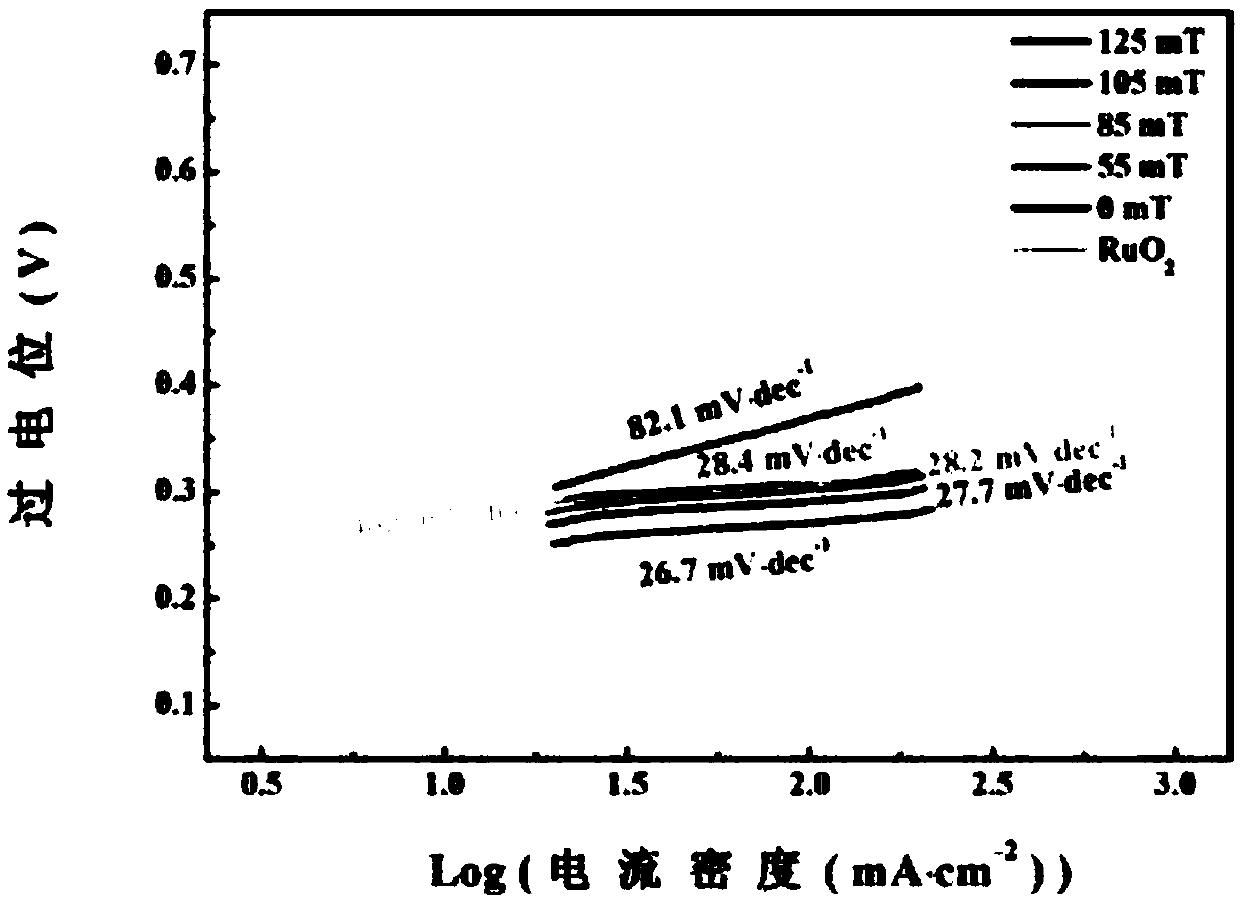

[0053] First test the Co when there is no external magnetic field 3 o 4 The LSV curve of the oxyg...

Embodiment 2

[0056] A layer of precursor material containing nickel and cobalt was grown on foamed Cu by hydrothermal method, and then it was heat-treated in a muffle furnace at 400°C for 3 hours to make NiCo 2 o 4 The catalysts are directly grown on foamed Cu. The surface will be grown with Co 3 o 4 The foam Cu of the catalyst was used as the working electrode, and the CHI 760E electrochemical workstation was used to characterize the oxygen evolution performance of the catalyst in electrolysis of water, which was carried out in a three-electrode system electrolyzer at room temperature. Among them, the electrolyte is 1M KOH solution, the counter electrode is Pt sheet, and the reference electrode is Ag / AgCl electrode. The electrochemical behavior is mainly analyzed using linear sweep voltammetry (LSV) curves and Tafel curves, and the scanning speed of LSV is always set to 5mV / s.

[0057] First test the NiCo when the magnetic field strength is 0 2 o 4 The LSV curve of the oxygen evolut...

Embodiment 3

[0062] NiCo 2 o 4 The catalyst powder was mixed with anhydrous ethanol and naphthol solvents and coated on the glassy carbon electrode to form a working electrode. The CHI 760E electrochemical workstation was used to characterize the oxygen evolution performance of the catalyst in electrolysis of water at room temperature in a three-electrode system electrolytic cell. Among them, the electrolyte is 1M KOH solution, the counter electrode is Pt sheet, and the reference electrode is Ag / AgCl electrode. The electrochemical behavior is mainly analyzed using linear sweep voltammetry (LSV) curves and Tafel curves, and the scanning speed of LSV is always set to 5mV / s.

[0063] Test NiCo first 2 o 4 The LSV curve of the oxygen evolution catalyst when the magnetic field strength is 0, and the catalytic performance without a magnetic field is obtained. After the test, adjust the strength of the applied magnetic field to 100mT and keep it constant, and then drive the rotation of the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com