Preparation process of super-hydrophobic super-self-cleaning anti-pollution flashover insulator applied to electric power system

A technology of power system and preparation process, applied in insulators, antifouling/underwater coatings, circuits, etc., can solve the problems of decreased hydrophobicity and insufficient hydrophobicity, and achieve the effect of maintenance-free

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation process for an ultra-hydrophobic, ultra-self-cleaning, anti-pollution flashover insulator applied to a power system, comprising the following steps:

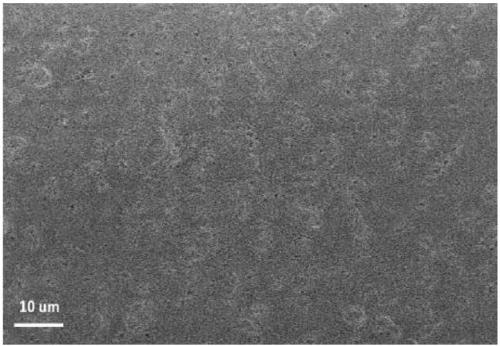

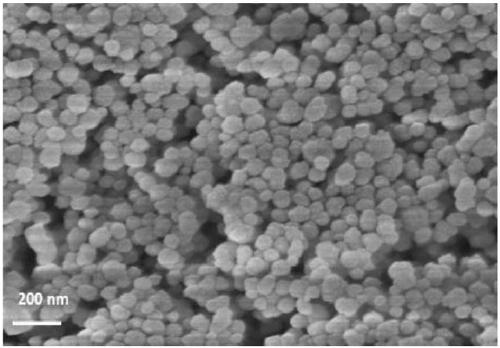

[0042] (1) Preparation of nano-silica particles: Dissolve 300mL of TEOS in ethanol to obtain a mixture of 3.5L of absolute ethanol and TEOS, and pour the mixture of TEOS and absolute ethanol into an electric stirring paddle, dripping In a 5L flask with a capacity of funnel and condenser, the dropping funnel contains ammonia solution prepared according to the volume ratio of distilled water and ammonia water at 2:7, turn on the electric stirrer, and at the same time turn on and adjust the switch of the dropping funnel to make 180mL of ammonia The aqueous solution was evenly dropped into the three-necked flask at a rate of 15mL / min. After the distilled aqueous solution of ammonia was added dropwise, continue stirring for 1 hour to obtain nano-silica sol. Dry the nano-silica sol in a drying oven at 120°C for 24 ...

Embodiment 2

[0047] All the other are the same as Example 1, except that: the consumption of TEOS in the step (1) is 400ml, and the nano-silica sol is dried in a drying oven at 115°C for 26h; The consumption of methyl siloxane is 0.6g, the consumption of dibutyltin dilaurate is 0.06g, the consumption of nano silicon dioxide is 6g, and described water bath temperature is 58 ℃, and the consumption of acidic ultrapure water is 6ml; Described step ( 4) The temperature of the middle oven is 115°C, and the baking time is 25 minutes.

Embodiment 3

[0049] All the other are the same as Example 1, except that: the consumption of TEOS in the step (1) is 350ml, and the nano-silica sol is dried in a drying oven at 125°C for 22h; The consumption of methyl siloxane is 0.4g, the consumption of dibutyltin dilaurate is 0.04g, the consumption of nano silicon dioxide is 4g, and described water bath temperature is 62 ℃, and the consumption of acidic ultrapure water is 4ml; Described step ( 4) The temperature of the middle oven is 125°C, and the baking time is 15 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com