Full-automatic sorting and conveying system for parts

A conveying system, fully automatic technology, applied in the direction of sorting, conveyor objects, transportation and packaging, etc., can solve the problems of heavy manual workload, low accuracy rate, complex system as a whole, and achieve simple structure and high accuracy rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

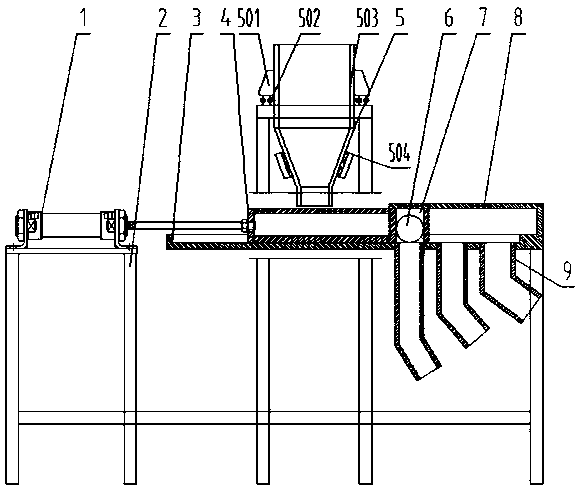

[0012] see figure 1 , a fully automatic sorting and conveying system for parts, comprising a chute 3, a slider 4, a discharge pipe 9, and a feeding device 5, characterized in that: the front end of the slider 4 is provided with a material receiving trough 7, and the The chute 3 is provided with a guide rail groove compatible with the slide block 4, and a cover plate 8 is fixed above the rear portion of the chute 3, and the lower end surface of the cover plate 8 is aligned with the upper end surface of the slide block 4, so that Below the rear part of the chute 3, several groups of discharge pipes 9 are fixed, and the widths of the multiple groups of discharge pipes 9 increase from front to rear, and the discharge pipes 9 are aligned with the receiving trough 7 along the vertical plane. The rear end of the slide block 4 is connected with the piston rod of the cylinder 1, the feeding device 5 is made up of a hopper 503 and a vibrator 504, the tapered outlet at the lower end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com