Production process of outwards-buckled type paper cup cover

A production process and technology of paper cups, applied in the field of paper cup lids, can solve problems such as poor sealing, affecting use, and easy detachment of cup lids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

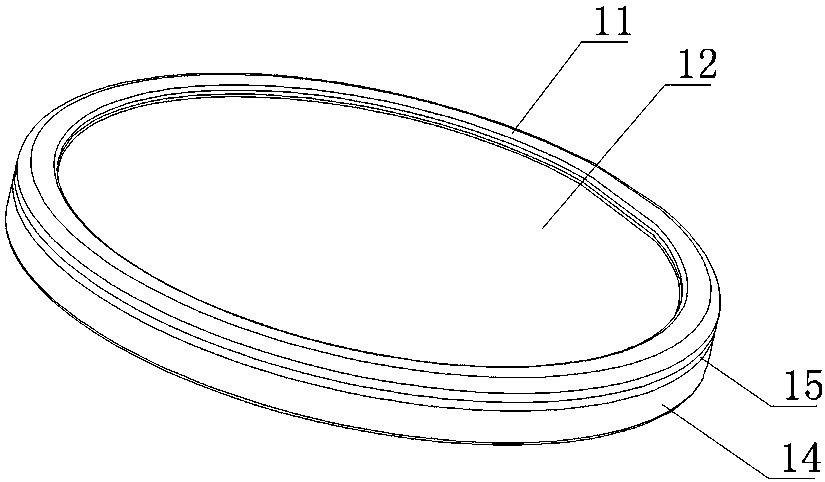

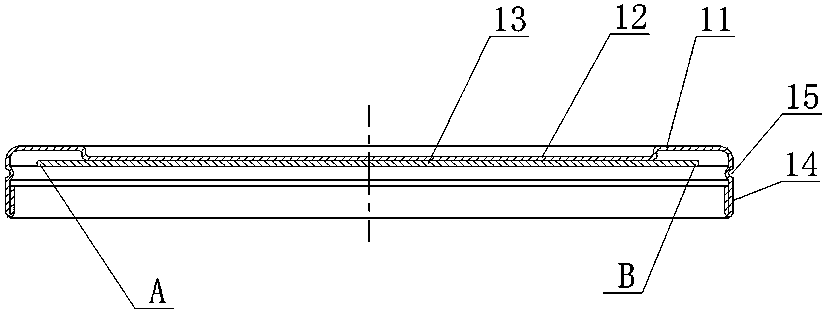

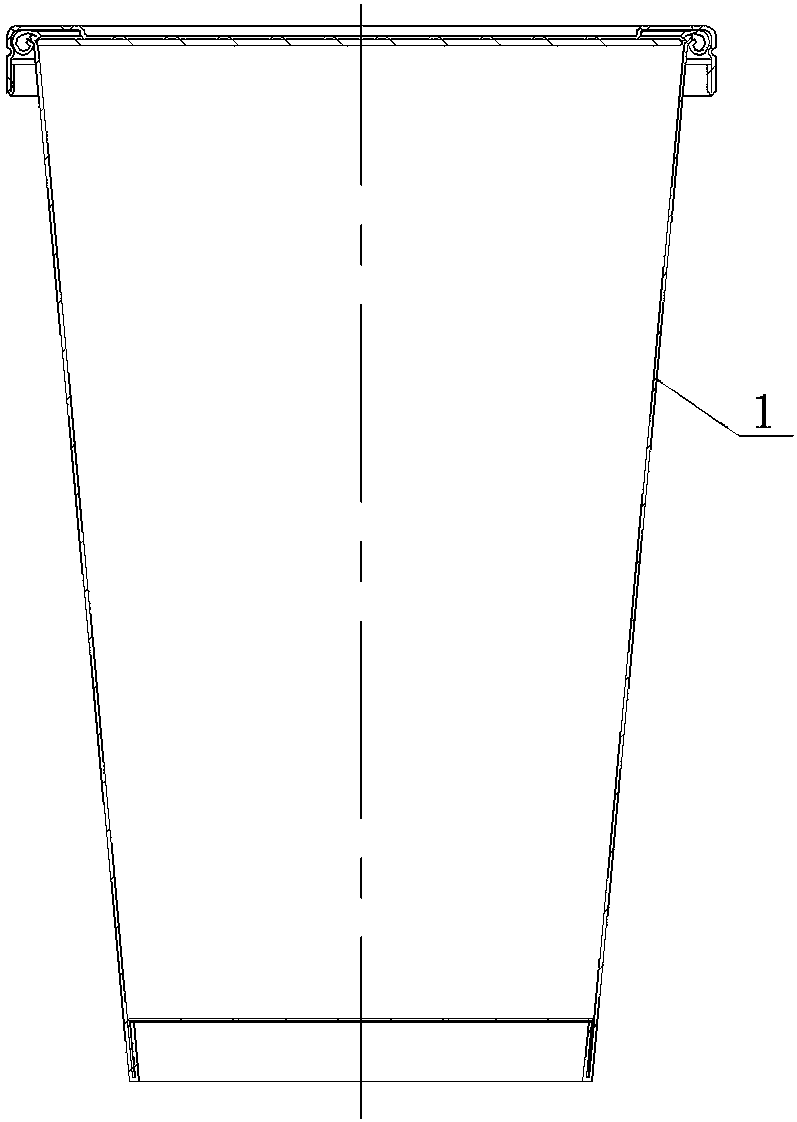

[0016] Such as Figure 1-5 As shown, the paper cup with an inner sill includes a cup body 1 made of paper sheets. The inner sill 3 protruding in the direction; the outer buckle type paper cup lid, including the lid body 11, the lid body 11 is provided with the outer edge 14 of the lid buckled outside the mouth of the paper cup, and the top center of the lid body 11 is provided with a lower The bottom of the sunken step 12 is pasted with the inner buckle paper 13 corresponding to the inner sill 3 of the paper cup. The inner buckle paper 13 and the cup lid body 11 have a certain eccentricity, and the A end of the inner buckle paper 13 is the largest Eccentric end, B end is the smallest eccentric end, when the paper cup cover covers the mouth of the paper cup with inner sill, the A end of the inner buckle paper 13 is inserted into the bottom of the inner sill of the paper cup to buckle the inner sill 3, and the B end leaves the paper cup Inner sill 3; the side wall of the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com